CHAPTER NINE: QUALITY AND QUANTITY CONTROL

9.1 INTRODUCTION

Most of the above characteristics are related to products. Similarly, some of the quality characteristics of services are meeting promised due dates, safety, comfort, security, less waiting time and so forth. So, the various dimensions of quality are performance, features, reliability, conformance, durability, serviceability, aesthetics, perceived quality, safety, comfort, security, commitment to due dates, less waiting time, etc.

9.2 QUALITY

Different meaning could be attached to the word quality under different circumstances. The word quality does not mean the quality of manufactured product only. It may refer to the quality of the process (i.e., men, material, and machines) and even that of management. Where the quality manufactured product referred as or defined as “Quality of product as the degree in which it fulfills the requirement of the customer. It is not absolute but it judged or realized by comparing it with some standards”. Quality begins with the design of a product in accordance with the customer specification further it involved the established measurement standards, the use of proper material, selection of suitable manufacturing process etc., quality is a relative term and it is generally used with reference to the end use of the product.

Crosby defined as “Quality is conformance to requirement or specifications”.

Objectives:

a) Fundamental factors affecting quality

b) Importance of quality control

c) Quality Circles, Six sigma

d) Total Quality Management (TQM), Just In Time (JIT)

e) ISO 9000 Series, ISO 14000 Series

f) Inspection

Juran defined as “Quality is fitness for use”. “The Quality of a product or service is the fitness of that product or service for meeting or exceeding its intended use as required by the customer.” Dimensions of quality

a) Performance – How well the product or service performs the customers intended use. e.g. the speed of a computer.

b) Features- the special characteristics that appeal to customers e.g. power seats on a car.

c) Reliability- the likelihood of breakdowns, malfunctions and the need for repairs.

d) serviceability – the speed, cost, and convenience of repairs and maintenance

e) Durability- the effects on human sense- the look, feel, taste, smell or sound.

f) Customer service- the treatment received by customers before, doing and after sale.

g) How well product protects users before during and after use.

Fundamental Factors Affecting Quality

The nine fundamental factors (9 M’s), which are affecting the quality of products and services, are: markets, money, management, men, motivation, materials, machines and mechanization.

Modern information methods and mounting product requirements.

1. Market: Because of technology advancement, we could see many new products to satisfy customer wants. At the same time, the customer wants are also changing dynamically. So, it is the role of companies to identify needs and then meet it with existing technologies or by developing new technologies.

2. Money: The increased global competition necessitates huge outlays for new equipments and process. This should be rewarded by improved productivity. This is possible by minimizing quality costs associated with the maintenance and improvements of quality level.

3. Management: Because of the increased complex structure of business organization, the quality related responsibilities lie with persons at different levels in the organization.

4. Men: The rapid growth in technical knowledge leads to development of human resource with different specialization. This necessitates some groups like, system engineering group to integrate the idea of full specialization.

5. Motivation: If we fix the responsibility of achieving quality with each individual in the organization with proper motivation techniques, there will not be any problem in producing the designed quality products.

6. Materials: Selection of proper materials to meet the desired tolerance limit is also an important consideration. Quality attributes like, surface finish, strength, diameter etc., can be obtained by proper selection of material.

7. Machines and mechanization: In order to have quality products which will lead to higher productivity of any organization, we need to use advanced machines and mechanize various operations.

8. Modern information methods: The modern information methods help in storing and retrieving needed data for manufacturing, marketing and servicing.

9. Mounting product requirements: Product diversification to meet customers taste leads to intricacy in design, manufacturing and quality standards. Hence, companies should plan adequate system to tackle all these requirements.

9.3 CONTROL

The process through which the standards are established and met with standards is called control.

This process consists of observing our activity performance, comparing the performance with some standard and then taking action if the observed performance is significantly too different from the standards.

The control process involves a universal sequence of steps as follows:

1. Choose the control object

2. Choose a unit of measure

3. Set the standard value

4. Choose a sensing device which can measure

5. Measure actual performance

6. Interpret the difference between actual and standard

7. Taking action.

Need for Controlling Quality

In the absence of quality, the following will result:

1. No yardstick for comparing the quality of goods/services.

2. Difficulty in maintaining consistency in quality.

3. Dissatisfied customers due to increased maintenance and operating costs of products/services.

4. Increased rework cost while manufacturing products/providing services.

5. Reduced life time of the products/services.

6. Reduced flexibility with respect to usage of standard spare parts.

7. Hence, controlling quality is an essential activity.

1.6 QUALITY CONTROL

Quality Control (QC) may be defined as a system that is used to maintain a desired level of quality in a product or service. It is a systematic control of various factors that affect the quality of the product. It depends on materials, tools, machines, type of labour, working conditions etc.

QC is a broad term, it involves inspection at particular stage but mere inspection does not mean QC. As opposed to inspection, in quality control activity emphasis is placed on the quality future production. Quality control aims at prevention of defects at the source, relies on effective feedback system and corrective action procedure. Quality control uses inspection as a valuable tool. According to Juran “Quality control is the regulatory process through which we measure actual quality performance, compare it with standards, and act on the difference”. Another definition of quality control is from ANSI/ASQC standard (1978) quality control is defined as “The operational techniques and the activities which sustain a quality of product or service that will satisfy given needs; also the use of such techniques and activities”. Alford and Beatty define QC as “In the broad sense, quality control is the mechanism by which products are made to measure up to specifications determined from customers, demands and transformed into sales engineering and manufacturing requirements, it is concerned with making things right rather than discovering and rejecting those made wrong”.

Types of Quality Control QC is not a function of any single department or a person. It is the primary responsibility of any

supervisor to turn out work of acceptable quality. Quality control can be divided into three main sub-areas, those are:

1. Off-line quality control,

2. Statistical process control, and

3. Acceptance sampling plans.

1. Off-line quality control: Its procedure deal with measures to select and choose controllable product and process parameters in such a way that the deviation between the product or process output and the standard will be minimized. Much of this task is accomplished through product and process design.

Example: Taguchi method, principles of experimental design etc.

2. Statistical process control: SPC involves comparing the output of a process or a service with a standard and taking remedial actions in case of a discrepancy between the two. It also involves determining whether a process can produce a product that meets desired

specification or requirements. On-line SPC means that information is gathered about the product, process, or service while it is functional. The corrective action is taken in that operational phase. This is real-time basis.

3. Acceptance sampling plans: A plan that determines the number of items to sample and the acceptance criteria of the lot, based on meeting certain stipulated conditions (such as the risk of rejecting a good lot or accepting a bad lot) is known as an acceptance sampling plan.

Steps in Quality Control

Following are the steps in quality control process:

1. Formulate quality policy.

2. Set the standards or specifications on the basis of customer’s preference, cost and profit.

3. Select inspection plan and set up procedure for checking.

4. Detect deviations from set standards of specifications.

5. Take corrective actions or necessary changes to achieve standards.

6. Decide on salvage method i.e., to decide how the defective parts are disposed of, entire scrap or rework.

7. Coordination of quality problems.

8. Developing quality consciousness both within and outside the organization.

9. Developing procedures for good vendor-vendee relations.

Objectives of Quality Control

Following are the objectives of quality control:

1. To improve the companies income by making the production more acceptable to the

customers, i.e., by providing long life, greater usefulness, maintainability etc.

2. To reduce companies cost through reduction of losses due to defects.

3. To achieve interchangeability of manufacture in large scale production.

4. To produce optimal quality at reduced price.

5. To ensure satisfaction of customers with productions or services or high quality level, to build

customer goodwill, confidence and reputation of manufacturer.

6. To make inspection prompt to ensure quality control.

7. To check the variation during manufacturing.

The broad areas of application of quality control are incoming material control, process control and product control.

Benefits of Quality Control

Improving the quality of products and services.

Increasing the productivity of manufacturing processes, commercial business, corporations.

Reducing manufacturing and corporate costs.

Determining and improving the marketability of products and services.

Reducing consumer prices of products and services.

Improving and/or assuring on time deliveries and availability.

Assisting in the management of an enterprise.

Seven Tools for Quality Control

To make rational decisions using data obtained on the product, or process, or from the consumer, organizations use certain graphical tools. These methods help us learn about the characteristics of a process, its operating state of affairs and the kind of output we may expect from it. Graphical methods are easy to understand and provide comprehensive information; they are a viable tool

for the analysis of product and process data. These tools are effect on quality improvement. The seven quality control tools are:

1. Pareto charts 2. Check sheets 3. Cause and effect diagram

4. Scatter diagrams 5. Histogram 6. Graphs or flow charts

7. Control charts

9.4 QUALITY CIRCLES

The quality circles begun in Japan in 1960s.

The concept of quality circles is based on the participating style of management. It assumes that productivity will improve through an uplift of morale and motivations which are in turn achieved through consultation and discussion in informal groups.

One organizational mechanism for worker participation in quality is the quality circle. It is typically an informal group of people that consists of operators, supervisors, managers and soon who get together to improve ways to make the product or deliver the service.

According to Juran, quality circle defined as “a group of work force level people, usually from within one department, who volunteer to meet weekly (on company time) to address quality problems that occur within their department.”

Quality circle members select the problems and are given training is problem-solving techniques. A quality circle can be an effective productivity improvement tool because it generates new ideas and implements them. Where the introduction of quality circle is capably planned and where the company environment is supporting they are highly successful. The benefits fall into two categories: those are measurable saving and improvement in the attitudes and behavior of people.

Quality circles pursue two types of problems, those concerned with the personal well being of the worker and those concerned with the well being of company. Benefits of Quality Circle The most important benefit of quality circles is their effect on people’s attitudes fall into three categories:

1. Quality Circles Effect on Individual Characteristics

(a) Quality circles enable the individual to improve personal capabilities—group participation

and learning specific problem-solving tools.

(b) Quality circles increase the individual’s self-respect.

(c) Quality circles help worker change certain personality characteristics—shy person become as active.

2. Quality Circles Effect on Individuals Relations with Other

(a) Quality circles increase the respect of the supervisor for the worker.

(b) Quality circles increase workers understanding of the difficulties faced by supervisors— problem selection, solving and implementations.

(c) Quality circle increase management’s respect for worker.

3. Quality Circles Effect on Workers and Their Attributes

(a) Quality circles change some workers negative attitudes.

(b) Quality circle reduces conflict stemming from the working environment.

(c) Quality circles help workers to understand better the reasons while many problems solved quickly.

Quality circles, as a management tool, are based on the following basic principles of people:

(a) People want to do a good job.

(b) People want to be recognized as intelligent, interested employees and to participate in

decisions affecting their work.

(c) People want information to better understand goals and problems of their organization and make informed decisions.

(d) Employees want recognition and responsibility and a feeling of self-esteem. Motivational methods are not enough for successful quality circle programs. Management support, technical knowledge, and statistical procedures are essential.

9.5 TOTAL QUALITY MANAGEMENT

Now-a-days, customers demand products/services with greater durability and reliability at the most economic price. This forces producers to strictly follow quality procedures right from design till shipment and installation of the products. So that goal of any competitive industry is to provide a product or service at the most economical costs, ensuring full customer satisfaction.

This can be achieved through Total Quality Management (TQM), because, quality is not a technical function, but a systemic process extending throughout all phases of the business, e.g., marketing, design, development, engineering, purchasing, production/operations.

As per Feigebaum, “Total Quality Management is an effective system of integrating the quality development, quality maintenance and quality improvement efforts of various groups in an organization so as to enable marketing, engineering, production and service at the most economical levels which allow for full customer satisfaction”.

Benefits of TQM

The benefits of TQM can be classified into the following two categories:

1. Customer satisfaction oriented benefits.

2. Economic improvements oriented benefits.

1. Customer satisfaction oriented benefits: The benefits under this category are listed below:

(a) Improvement in product quality.

(b) Improvement in product design.

(c) Improvement in production flow.

(d) Improvement in employee morale and quality consciousness.

(e) Improvement of product service.

(f) Improvement in market place acceptance.

2. Economic improvements oriented benefits: The benefits under this category are as follows:

(a) Reductions in operating costs.

(b) Reductions in operating losses.

(c) Reductions in field service costs.

(d) Reductions in liability exposure.

9.6 SIX SIGMA MAINTENANCE

It is the application of six sigma principles in maintenance. Six sigma is a maintenance process that focuses on reducing the variation in business production processes. By reducing variation, a business can achieve tighter control over its operational systems, increasing their cost effectiveness and encouraging productivity breakthrough. Six sigma is a term created at Motorola to describe the goal and process used to achieve breakthrough levels of quality improvement. Sigma is the Greek symbol used by statisticians to

refer to the six standard deviations. The term six sigma refers to a measure of process variation (six standard deviations) that translates into an error or defect rate of 3.4 parts per million. To achieve quality performance of six sigma level, special sets of quality improvement

methodologies and statistical tools developed. These improvement methods and statistical tools are taught to a small group of workmen known as six sigma champions who are assigned full-time responsibility to define, measure, analyze, improve and control process quality. They also facilitate the improvement process by removing the organizational roadblocks encountered. Six sigma methodologies improve any existing business process by constantly reviewing and re-tuning the process.

To achieve this, six sigma uses a methodology known as DMAIC (Define opportunities, Measure performance, Analyse opportunity, Improve performance, Control performance). This six sigma process is also called DMAIC process. Six sigma relies heavily on statistical

techniques to reduce failures and it incorporates the basic principles and techniques used in Business, Statistics, and Engineering. Six sigma methodologies can also be used to create a brand new business process from ground up using design for six sigma principles.

Six Sigma Maintenance Process The steps of six sigma maintenance are same as DMAIC process. To apply six sigma in

maintenance, the work groups that have a good understanding of preventive maintenance techniques in addition to a strong leadership commitment. Six sigma helps in two principal inputs to the maintenance cost equation: Reduce or eliminate the need to do maintenance

(reliability of equipment), and improve the effectiveness of the resources needed to accomplish maintenance. Following are the steps involved in six sigma maintenance process.

Define

This step involves determining benchmarks, determining availability and reliability requirements, getting customer commitments and mapping the flow process.

Measure

This step involves development of failure measurement techniques and tools, data collection process, compilation and display of data.

Analysis

This step involves checking and verifying the data and drawing conclusions from data. It also involves determining improvement opportunities, finding root causes and map causes.

Improve

This step involves creating model equipment and maintenance process, total maintenance plan and schedule and implementing those plans and schedule.

Control

This step involves monitoring the improved programme. Monitor improves performance and assesses effectiveness and will make necessary adjustments for the deviation if exists.

Lean Maintenance

Lean maintenance is the application of lean principle in maintenance environments.

Lean system recognizes seven forms of waste in maintenance. They are over production, waiting, transportation, process waste, inventory, waste motion and defects. In lean maintenance, these wastes are identified and efforts are made for the continuous improvement in process by eliminating the wastes. Thus, lean maintenance leads to maximize yield, productivity and profitability. Lean maintenance is basically equipment reliability focused and reduces need for maintenance troubleshooting and repairs. Lean maintenance protects equipments and system from the route causes of malfunctions, failures and downtime stress. From the sources of waste uptime can be

improved and cost can be lowered for maintenance.

9.7 ISO 9000 SERIES

ISO stands for International Organization for Standardization. It is an international body, which consists of representatives from more than 90 countries. The national standard bodies of these countries are the members of this organization. Bureau of Indian Standards (BIS) are the Indian representative to ISO, ISO and International Electro Technical Commission (IEC)) operate jointly as a single system. These are non-governmental organizations, which exist to provide common standards on international trade of goods and services.

ISO 9000 standards expect firms to have a quality manual that meets ISO guidelines, documents, quality procedures and job instructions, and verification of compliance by third-party auditors.

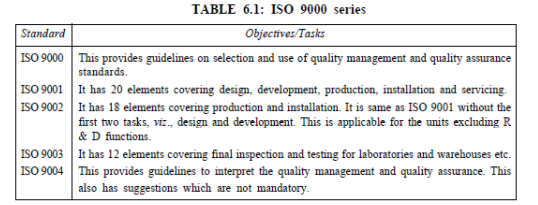

ISO 9000 series has five international standards on quality managements. They are:

1. ISO 9000 — Quality management and Quality assurance standards

2. ISO 9001 — Quality systems: Quality in design

3. ISO 9002 — Quality systems: Production and Installation

4. ISO 9003 — Quality systems: Final inspection and test

5. ISO 9004 — Quality management and systems

Objectives of ISO 9000 Series

The objectives of ISO 9000 series is listed in Table 6.1.

Benefits of ISO 9000 Series

ISO 9000 series provides several tangible and intangible benefits which are listed below:

1. This gives competitive advantage in the global market.

2. Consistency in quality, since ISO helps in detecting non-conformity early which makes it possible to take corrective action.

3. Documentation of quality procedures adds clarity to quality system.

4. ISO 9000 ensures adequate and regular quality training for all members of the organization.

5. ISO helps the customers to have cost effective purchase procedure.

6. The customers while making purchases from companies with ISO certificate need not spend much on inspection and testing. This will reduce the quality cost and lead-time.

7. This will help in increasing productivity.

8. This will aid to improved morale and involvement of workers.

9. The level of job satisfaction would be more.

Steps in ISO 9000 Registration

1. Selection of appropriate standard from ISO 9001, ISO 9002 and ISO 9003 using the guidelines

given in ISO 9000.

2. Preparation of quality manual to cover all the elements in the selected model.

3. Preparation of procedures and shop floor instructions which are used at the time of implementing the system. Also document these items.

4. Self-auditing to check compliance of the selected model.

5. Selection of a registrar and making application to obtain certificate for the selected model.

A registrar is an independent body with knowledge and experience to evaluate any one of the three models of the company’s quality system (ISO 9002). Registrars are approved and certified by acridities.

The registrar, on successful verification and assessment will register the company. Before selecting a registrar, one should know the following:

1. Accreditors of the registrar.

2. Background and credibility of the registrar.

3. Cost of registration through the proposed registrar.

4. Expected harmony between the company and the potential registrar while working towards

implementing ISO model in the company.

9.8 JUST-IN-TIME (JIT) MANUFACTURING

Introduction

Just-In-Time (JIT) Manufacturing is a philosophy rather than a technique. By eliminating all waste and seeking continuous improvement, it aims at creating manufacturing system that is response to the market needs.

The phase just in time is used to because this system operates with low WIP (Work-In- Process) inventory and often with very low finished goods inventory.

Products are assembled just before they are sold, subassemblies are made just before they are assembled and components are made and fabricated just before subassemblies are made. This leads to lower WIP and reduced lead times. To achieve this organizations have to be

excellent in other areas e.g. quality. According to Voss, JIT is viewed as a “Production methodology which aims to improve overall

productivity through elimination of waste and which leads to improved quality”. JIT provides an efficient production in an organization and delivery of only the necessary parts in the right quantity, at the right time and place while using the minimum facilities”.

Benefits of JIT

The most significant benefit is to improve the responsiveness of the firm to the changes in the market place thus providing an advantage in competition. Following are the benefits of JIT:

1. Product cost—is greatly reduced due to reduction of manufacturing cycle time, reduction of waste and inventories and elimination of non-value added operation.

2. Quality—is improved because of continuous quality improvement programmes.

3. Design—Due to fast response to engineering change, alternative designs can be quickly brought on the shop floor.

4. Productivity improvement.

5. Higher production system flexibility.

6. Administrative and ease and simplicity.

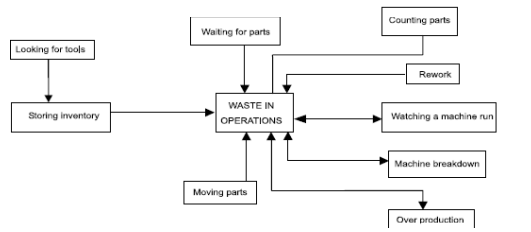

SEVEN WASTES

Shiego Shingo, a Japanese JIT authority and engineer at the Toyota Motor Company identifies seven wastes as being the targets of continuous improvement in production process. By attending to these wastes, the improvement is achieved.

1. Waste of over production eliminate by reducing set-up times, synchronizing quantities and

timing between processes, layout problems. Make only what is needed now.

2. Waste of waiting eliminate bottlenecks and balance uneven loads by flexible work force and equipment.

3. Waste of transportation establish layouts and locations to make handling and transport unnecessary if possible. Minimize transportation and handling if not possible to eliminate.

4. Waste of processing itself question regarding the reasons for existence of the product and then why each process is necessary.

5. Waste of stocks reducing all other wastes reduces stocks.

6. Waste of motion study for economy and consistency. Economy improves productivity and consistency improves quality. First improve the motions, then mechanise or automate otherwise.

There is danger of automating the waste.

7. Waste of making defective products develop the production process to prevent defects from being produced, so as to eliminate inspection. At each process, do not accept defects and makes no defects. Make the process fail-safe. A quantify process always yield quality product.

Fig. 4.8 Wastes in operations

Benefits of JIT

The most significant benefit is to improve the responsiveness of the firm to the changes in the market place thus providing an advantage in competition. Following are the benefits of JIT:

1. Product cost—is greatly reduced due to reduction of manufacturing cycle time, reduction of waste and inventories and elimination of non-value added operation.

2. Quality—is improved because of continuous quality improvement programmes.

3. Design—Due to fast response to engineering change, alternative designs can be quickly brought on the shop floor.

4. Productivity improvement.

5. Higher production system flexibility.

6. Administrative and ease and simplicity.

Disadvantages of JIT approach

a) Faculty forecasting may lead to stock outs.

b) JIT requires establishment of system to link p buyers of suppliers

c) lack of safety stocks makes the firm vulnerable to fail.

d) Removes advantage of bill buying e.g. reduced prices.

e) Requires much training to break down barriers between functions within the organization

9.9 INSPECTION

Inspection is an important tool to achieve quality concept. It is necessary to assure confidence to manufacturer and aims satisfaction to customer. Inspection is an indispensable tool of modern manufacturing process. It helps to control quality, reduces manufacturing costs, eliminate scrap losses and assignable causes of defective work.

The inspection and test unit is responsible for appraising the quality of incoming raw materials and components as well as the quality of the manufactured product or service. It checks the components at various stages with reference to certain predetermined factors and detecting and sorting out the faulty or defective items. It also specified the types of inspection devices to use and the procedures to follow to measure the quality characteristics. Inspection only measures the degree of conformance to a standard in the case of variables.

In the case of attributes inspection merely separates the nonconforming from the conforming. Inspection does not show why the nonconforming units are being produced. Inspection is the most common method of attaining standardization, uniformity and quality of

workmanship. It is the cost art of controlling the production quality after comparison with the established standards and specifications. It is the function of quality control. If the said item does not fall within the zone of acceptability it will be rejected and corrective measure will be applied to see that the items in future conform to specified standards.

Objectives of Inspection

1. To detect and remove the faulty raw materials before it undergoes production.

2. To detect the faulty products in production whenever it is detected.

3. To bring facts to the notice of managers before they become serous to enable them discover weaknesses and over the problem.

4. To prevent the substandard reaching the customer and reducing complaints.

5. To promote reputation for quality and reliability of product.

Purpose of Inspection

1. To distinguish good lots from bad lots.

2. To distinguish good pieces from bad pieces.

3. To determine if the process is changing.

4. To determine if the process is approaching the specification limits.

5. To rate quality of product.

6. To rate accuracy of inspectors.

7. To measure the precision of the measuring instrument.

8. To secure products-design information.

9. To measure process capability.

Types of Inspection

Types of inspection are:

1. Floor inspection 2. Centralized inspection

3. Combined inspection 4. Functional inspection

5. First piece inspection 6. Pilot piece inspection

7. Final inspection

1. Floor Inspection

In this system, the inspection is performed at the place of production. It suggests the checking of materials in process at the machine or in the production time by patrolling inspectors. These inspectors move from machine to machine and from one to the other work centres. Inspectors have to be highly skilled. This method of inspection minimize the material handling, does not disrupt the line layout of machinery and quickly locate the defect and readily offers field and correction.

Advantages

1. Detection of errors of the source reduces scrap and rework.

2. Correction is done before it affects further production, resulting in saving cost of unnecessary work on defective parts.

3. Material handling time is reduced.

4. Job satisfaction to worker as he can’t be held responsible for bad work at a later date.

5. Greater number of pieces can be checked than a sample size.

6. Does not delay in production.

Disadvantages

1. Delicate instruments can be employed.

2. Measuring or inspection equipment have to be recalibrated often as they are subjected to wear

or dust.

3. High cost of inspection because of numerous sets of inspections and skilled inspectors.

4. Supervision of inspectors is difficult due to vibration.

5. Pressure on inspector.

6. Possibility of biased inspection because of worker.

Suitability

1. Heavy products are produced.

2. Different work centres are integrated in continuous line layout.

2. Centralised Inspection

Inspection is carried in a central place with all testing equipment, sensitive equipment is housed in air-conditioned area. Samples are brought to the inspection floor for checking. Centralised inspection may locate in one or more places in the manufacturing industry.

Advantages

1. Greater degree of inspection due to sensitive equipment.

2. Less number of inspectors and tools.

3. Equipment needs less frequency of recalibration.

4. Cost of inspection is reduced.

5. Unbiased inspection.

6. Supervision of inspectors made possible.

7. No distraction to the inspector.

Disadvantages

1. Defects of job are not revealed quickly for prevention.

2. Greater material handling.

3. High cost as products are subjected to production before they are prevented.

4. Greater delay in production.

5. Inspection of heavy work not possible.

6. Production control work is more complicated.

7. Greater scrap.

3. Combined Inspection

Combination of two methods whatever may be the method of inspection, whether floor or central.

The main objective is to locate and prevent defect which may not repeat itself in subsequent operation to see whether any corrective measure is required and finally to maintain quality economically.

4. Functional Inspection

This system only checks for the main function, the product is expected to perform. Thus an electrical motor can be checked for the specified speed and load characteristics. It does not reveal the variation of individual parts but can assure combined satisfactory performance of all parts put together. Both manufacturers and purchasers can do this, if large number of articles are needed at regular intervals. This is also called assembly inspection.

5. First Piece or First-Off Inspections

First piece of the shift or lot is inspected. This is particularly used where automatic machines are employed. Any discrepancy from the operator as machine tool can be checked to see that the product is within in control limits. Excepting for need for precautions for tool we are check and disturbance in machine set up, this yields good result if the operator is careful.

6. Pilot Piece Inspection

This is done immediately after new design or product is developed. Manufacturer of product is done either on regular shop floor if production is not disturbed. If production is affected to a large extent, the product is manufactured in a pilot plant. This is suitable for mass production and products involving large number of components such as automobiles aeroplanes etc., and modification are design or manufacturing process is done until satisfactory performance is assured or established.

7. Final Inspection

This is also similar to functional or assembly inspection. This inspection is done only after completion of work. This is widely employed in process industries where there is not possible such as, electroplating or anodizing products. This is done in conjunction with incoming material inspection.

Methods of Inspection

There are two methods of inspection. They are: 100% inspection and sampling inspection.

1. 100% INSPECTION

This type will involve careful inspection in detail of quality at each strategic point or stage of manufacture where the test is involved is non-destructive and every piece is separately inspected. It requires more number of inspectors and hence it is a costly method. There is no sampling error.

This is subjected to inspection error arising out of fatigue, negligence, difficulty of supervision etc.

Hence, completer accuracy of influence is seldom attained. It is suitable only when a small number of pieces are there or a very high degree of quality is required. Example: Jet engines, aircraft, medical and scientific equipment.

2. SAMPLING INSPECTION

In this method randomly selected samples are inspected. Samples taken from different patches of products are representatives. If the sample proves defective, the entire concerned is to be rejected or recovered. Sampling inspection is cheaper and quicker. It requires less number ofInspectors. It is subjected to sampling errors but the magnitude of sampling error can be estimated. In the case of destructive test, random or sampling inspection is desirable. This type of inspection governs wide currency due to the introduction of automatic machines or equipments which are less susceptible to chance variable and hence require less inspection, suitable for inspection of products which have less precision importance and are less costly. Example: Electrical bulbs, radio bulbs, washing machine etc.

Drawbacks of Inspection

Following are the disadvantages of inspection:

1. Inspection adds to the cost of the product but not for its value.

2. It is partially subjective, often the inspector has to judge whether a products passes or not.

3. Fatigue and Monotony may affect any inspection judgment.

4. Inspection merely separates good and bad items. It is no way to prevent the production of bad items.

REVIEW QUESTIONS

i. Discuss the different types of inspection.

ii. Discuss the seven tools for quality control.

iii. Discuss the fundamental factors affecting quality.

iv. Discuss the ‘9 M’’s of quality of product or service.

v. Explain the benefits of TQM.

vi. What are the benefits of ISO 9000 series?