CHAPTER TEN: PLANT LOCATION AND LAYOUT

10.1 INTRODUCTION AND MEANING

Plant location or the facilities location problem is an important strategic level decision making for an organization. One of the key features of a conversion process (manufacturing system) is the efficiency with which the products (services) are transferred to the customers.

This fact will include the determination of where to place the plant or facility. The selection of location is a key-decision as large investment is made in building plant and machinery. It is not advisable or not possible to change the location very often. So an improper location of plant may lead to waste of all the investments made in building and machinery, equipment.

Before a location for a plant is selected, long range forecasts should be made anticipating future needs of the company. The plant location should be based on the company’s expansion plan and policy, diversification plan for the products, changing market conditions, the changing sources of raw materials and many other factors that influence the choice of the location decision. The purpose of the location study is to find an optimum location one that will result in the greatest advantage to the organization.

10.2 NEED FOR SELECTING A SUITABLE LOCATION

The need for selecting a suitable location arises because of three situations

I. When starting a new organisation, i.e., location choice for the first time.

II. In case of existing organisation.

III. In case of Global Location.

Objectives:

a) Need for Selecting a Suitable Location

b) Factors Influencing Plant/Facility Location

c) Discuss the location Theories

d) Describe the location Models

I. In Case of Location Choice for the First Time or New Organisations

Cost economies are always important while selecting a location for the first time, but should keep in mind the cost of long-term business/organisational objectives. The following are the factors to be considered while selecting the location for the new organisations:

1. Identification of region:

The organisational objectives along with the various long-term considerations about marketing, technology, internal organisational strengths and weaknesses, region specific resources and business environment, legal-governmental environment, social environment and geographical environment suggest a suitable region for locating the operations facility.

2. Choice of a site within a region: Once the suitable region is identified, the next step is choosing the best site from an available set. Choice of a site is less dependent on the organisation’s long-term strategies. Evaluation of alternative sites for their tangible and

intangible costs will resolve facilities-location problem. The problem of location of a site within the region can be approached with the following cost oriented non-interactive model, i.e., dimensional analysis.

3. Dimensional analysis: If all the costs were tangible and quantifiable, the comparison and selection of a site is easy. The location with the least cost is selected. In most of the cases intangible costs which are expressed in relative terms than in absolute terms. Their relative

merits and demerits of sites can also be compared easily. Since both tangible and intangible costs need to be considered for a selection of a site, dimensional analysis is used. Dimensional analysis consists in computing the relative merits (cost ratio) for each of the cost

items for two alternative sites. When starting a new factory, plant location decisions are very important because they have direct

bearing on factors like, financial, employment and distribution patterns. In the long run, relocation of plant may even benefit the organization. But, the relocation of the plant involves stoppage of production, and also cost for shifting the facilities to a new location. In addition to these things, it will introduce some inconvenience in the normal functioning of the business. Hence, at the time of starting any industry, one should generate several alternate sites for locating the plant. After a critical analysis, the best site is to be selected for commissioning the plant.

Location of warehouses and other facilities are also having direct bearing on the operational performance of organizations.

The existing firms will seek new locations in order to expand the capacity or to place the existing facilities. When the demand for product increases, it will give rise to following decisions:

Whether to expand the existing capacity and facilities.

Whether to look for new locations for additional facilities.

Whether to close down existing facilities to take advantage of some new locations.

II. In Case of Location Choice for Existing Organization

In this case a manufacturing plant has to fit into a multi-plant operations strategy. That is, additional plant location in the same premises and elsewhere under following circumstances:

1. Plant manufacturing distinct products.

2. Manufacturing plant supplying to specific market area.

3. Plant divided on the basis of the process or stages in manufacturing.

4. Plants emphasizing flexibility.

The different operations strategies under the above circumstances could be:

1. Plants manufacturing distinct products: Each plant services the entire market area for the organization. This strategy is necessary where the needs of technological and resource inputs are specialized or distinctively different for the different product-lines.

For example, a high quality precision product-line should not be located along with other product-line requiring little emphasis on precision. It may not be proper to have too many contradictions such as sophisticated and old equipment, highly skilled and semi-skilled

personnel, delicates processes and those that could permit rough handlings, all under one roof and one set of managers. Such a setting leads to much confusion regarding the required emphasis and the management policies. Product specialization may be necessary in a highly competitive market. It may be necessary to exploit the special resources of a particular geographical area. The more decentralized these pairs are in terms of the management and in terms of their physical location, the better would be the planning and control and the utilization of the resources.

2. Manufacturing plants supplying to a specific market area: Here, each plant manufactures almost all of the company’s products. This type of strategy is useful where market proximity consideration dominates the resources and technology considerations. This strategy requires great deal of coordination from the corporate office. An extreme example of this strategy is that of soft drinks bottling plants.

3. Plants divided on the basis of the process or stages in manufacturing: Each production process or stage of manufacturing may require distinctively different equipment capabilities, labour skills, technologies, and managerial policies and emphasis. Since the products

of one plant feed into the other plant, this strategy requires much centralized coordination of the manufacturing activities from the corporate office that are expected to understand the various technological aspects of all the plants.

4. Plants emphasizing flexibility: This requires much coordination between plants to meet the changing needs and at the same time ensure efficient use of the facilities and resources. Frequent changes in the long-term strategy in order to improve be efficiently temporarily, are not healthy for the organization. In any facility location problem the central question is: ‘Is this a location at which the company can remain competitive for a long time?’

For an established organization in order to add on to the capacity, following are the ways:

(a) Expansion of the facilities at the existing site: This is acceptable when it does not violate the basic business and managerial outlines, i.e., philosophies, purposes, strategies and capabilities.

For example, expansion should not compromise quality, delivery, or customer service.

(b) Relocation of the facilities (closing down the existing ones): This is a drastic step which can be called as ‘Uprooting and Transplanting’. Unless there are very compelling reasons, relocation is not done. The reasons will be either bringing radical changes in technology, resource availability or other destabilization.

All these factors are applicable to service organizations, whose objectives, priorities and strategies may differ from those of hardcore manufacturing organizations.

III. In Case of Global Location

Because of globalization, multinational corporations are setting up their organizations in India and Indian companies are extending their operations in other countries. In case of global locations there is scope for virtual proximity and virtual factory.

10.3 VIRTUAL PROXIMITY

With the advance in telecommunications technology, a firm can be in virtual proximity to its customers. For a software services firm much of its logistics is through the information/ communication pathway. Many firms use the communications highway for conducting a large

portion of their business transactions. Logistics is certainly an important factor in deciding on a location—whether in the home country

or abroad. Markets have to be reached. Customers have to be contacted. Hence, a market presence in the country of the customers is quite necessary.

10.4 VIRTUAL FACTORY

Many firms based in USA and UK in the service sector and in the manufacturing sector often out sources part of their business processes to foreign locations such as India. Thus, instead of one’s own operations, a firm could use its business associates’ operations facilities. The Indian BPO firm is a foreign-based company’s ‘virtual service factory’. So a location could be one’s own or one’s business associates. The location decision need not always necessarily pertain to own operations.

10.5 REASONS FOR A GLOBAL/FOREIGN LOCATION

A. Tangible Reasons

The tangible reasons for setting up an operations facility abroad could be as follows:

Reaching the customer: One obvious reason for locating a facility abroad is that of capturing a share of the market expanding worldwide. The phenomenal growth of the GDP of India is a big reason for the multinationals to have their operations facilities in our country. An

important reason is that of providing service to the customer promptly and economically which is logistics-dependent. Therefore, cost and case of logistics is a reason for setting up manufacturing facilities abroad. By logistics set of activities closes the gap between production of goods/services and reaching of these intended goods/services to the customer to his satisfaction. Reaching the customer is thus the main objective. The tangible and intangible gains and costs depend upon the company defining for it as to what that ‘reaching’ means. The tangible costs could be the logistics related costs; the intangible costs may be the risk of operating is a foreign country. The gains are the

immediate gains; the intangible gains are an outcome of what the company defines the concepts of reaching and customer for it.

The other tangible reasons could be as follows:

(a) The host country may offer substantial tax advantages compared to the home country.

(b) The costs of manufacturing and running operations may be substantially less in that foreign country. This may be due to lower labour costs, lower raw material cost, better availability of the inputs like materials, energy, water, ores, metals, key personnel etc.

(c) The company may overcome the tariff barriers by setting up a manufacturing plant in a foreign country rather than exporting the items to that country.

B. Intangible Reasons

The intangible reasons for considering setting up an operations facility abroad could be as follows:

1. Customer-related Reasons

(a) With an operations facility in the foreign country, the firm’s customers may feel secure that the firm is more accessible. Accessibility is an important ‘service quality’ determinant.

(b) The firm may be able to give a personal tough.

(c) The firm may interact more intimately with its customers and may thus understand their requirements better.

(d) It may also discover other potential customers in the foreign location.

2. Organizational Learning-related Reasons

(a) The firm can learn advanced technology. For example, it is possible that cutting-edge technologies can be learn by having operations in an technologically more advanced country.

The firm can learn from advanced research laboratories/universities in that country. Such learning may help the entire product-line of the company.

(b) The firm can learn from its customers abroad. A physical location there may be essential towards this goal.

(c) It can also learn from its competitors operating in that country. For this reason, it may have to

be physically present where the action is.

(d) The firm may also learn from its suppliers abroad. If the firm has a manufacturing plant there, it will have intensive interaction with the suppliers in that country from whom there may be much to learn in terms of modern and appropriate technology, modern management methods, and new trends in business worldwide.

3. Other Strategic Reasons

(a) The firm by being physically present in the host country may gain some ‘local boy’ kind of psychological advantage. The firm is no more a ‘foreign’ company just sending its products across international borders. This may help the firm in lobbying with the government of that country and with the business associations in that country.

(b) The firm may avoid ‘political risk’ by having operations in multiple countries.

(c) By being in the foreign country, the firm can build alternative sources of supply. The firm could, thus, reduce its supply risks.

(d) The firm could hunt for human capital in different countries by having operations in those countries. Thus, the firm can gather the best of people from across the globe.

(e) Foreign locations in addition to the domestic locations would lower the market risks for the firm. If one market goes slow the other may be doing well, thus lowering the overall risk.

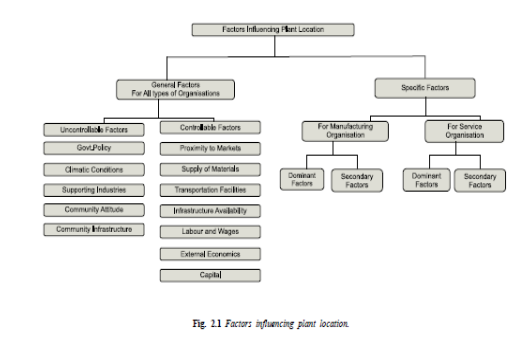

10.6 FACTORS INFLUENCING PLANT LOCATION/FACILITY LOCATION

Facility location is the process of determining a geographic site for a firm’s operations.

Managers of both service and manufacturing organizations must weigh many factors when assessing the desirability of a particular site, including proximity to customers and suppliers, labour costs, and transportation costs.

Location conditions are complex and each comprises a different Characteristic of a tangible(i.e. Freight rates, production costs) and non-tangible (i.e. reliability, Frequency security, quality) nature. Location conditions are hard to measure. Tangible cost based factors such as wages and products costs can be quantified precisely into what makes locations better to compare. On the other hand non-tangible features, which refer to such characteristics as reliability, availability and security, can only be measured along an ordinal or even nominal scale. Other non-tangible features like the percentage of employees that are unionized can be measured as well. To sumthis up non tangible features are very important for business location decisions. It is appropriate to divide the factors, which influence the plant location or facility location on the basis of the nature of the organisation as:

1. General locational factors, which include controllable and uncontrollable factors for all type of organisations.

2. Specific locational factors specifically required for manufacturing and service organizations.

Location factors can be further divided into two categories:

1. Dominant factors are those derived from competitive priorities (cost, quality, time, and flexibility) and have a particularly strong impact on sales or costs.

2. Secondary factors also are important, but management may downplay or even ignore some of them if other factors are more important.

General Locational Factors

Following are the general factors required for location of plant in case of all types of organisations.

Controllable Factors

1. Proximity to markets

2. Supply of materials

3. Transportation facilities

4. Infrastructure availability

5. Labour and wages

6. External economies

7. Capital

Fig. 2.1 Factors influencing plant location.

Uncontrollable Factors

1. Government policy

2. Climate conditions

3. Supporting industries and services

4. Community and labour attitudes

5. Community Infrastructure

Controllable Factors

1. Proximity to markets: Every company is expected to serve its customers by providing goods and services at the time needed and at reasonable price organizations may choose to locate facilities close to the market or away from the market depending upon the product. When the buyers for the product are concentrated, it is advisable to locate the facilities close to the market.

Locating nearer to the market is preferred if

• The products are delicate and susceptible to spoilage.

• After sales services are promptly required very often.

• Transportation cost is high and increase the cost significantly.

• Shelf life of the product is low.

Nearness to the market ensures a consistent supply of goods to customers and reduces the cost of transportation.

2. Supply of raw material: It is essential for the organization to get raw material in right qualities and time in order to have an uninterrupted production. This factor becomes very important if the materials are perishable and cost of transportation is very high.

General guidelines suggested by Yaseen regarding effects of raw materials on plant location are:

• When a single raw material is used without loss of weight, locate the plant at the raw material source, at the market or at any point in between.

• When weight loosing raw material is demanded, locate the plant at the raw material source.

• When raw material is universally available, locate close to the market area.

• If the raw materials are processed from variety of locations, the plant may be situated so as to minimize total transportation costs.

Nearness to raw material is important in case of industries such as sugar, cement, jute and cotton textiles.

3. Transportation facilities: Speedy transport facilities ensure timely supply of raw materials to the company and finished goods to the customers. The transport facility is a prerequisite for the location of the plant. There are five basic modes of physical transportation, air, road, rail, water and pipeline. Goods that are mainly intended for exports demand a location near to the port or large airport. The choice of transport method and hence the location will depend on relative costs, convenience, and suitability. Thus transportation cost to value added is one of the criteria for plant location.

4. Infrastructure availability: The basic infrastructure facilities like power, water and waste disposal, etc., become the prominent factors in deciding the location. Certain types of industries are power hungry e.g., aluminum and steel and they should be located close to the power station or location where uninterrupted power supply is assured throughout the year. The non-availability of power may become a survival problem for such industries. Process industries like paper, chemical, cement, etc., require continuous. Supply of water in large amount and good quality, and mineral content of water becomes an important factor. A waste disposal facility for process industries is an important factor, which influences the plant location.

5. Labour and wages: The problem of securing adequate number of labour and with skills specific is a factor to be considered both at territorial as well as at community level during plant location. Importing labour is usually costly and involve administrative problem. The history of labor relations in a prospective community is to be studied. Prospective community is to be studied. Productivity of labour is also an important factor to be considered. Prevailing wage patterns, cost of living and industrial relation and bargaining power of the unions’ forms in important considerations.

6. External economies of scale: External economies of scale can be described as urbanization and location economies of scale. It refers to advantages of a company by setting up operations in a large city while the second one refers to the “settling down” among other companies of related Industries. In the case of urbanization economies, firms derive from locating in larger cities rather than in smaller ones in a search of having access to a large pool of labour, transport facilities, and as well to increase their markets for selling their products and have access to a much wider range of business services.

Location economies of scale in the manufacturing sector have evolved over time and have mainly increased competition due to production facilities and lower production costs as a result of lower transportation and logistical costs. This led to manufacturing districts where many companies of related industries are located more or less in the same area. As large corporations have realized that inventories and warehouses have become a major cost factor, they have tried reducing inventory costs by launching “Just in Time” production system (the so called Kanban System).

This high efficient production system was one main factor in the Japanese car industry for being so successful. Just in time ensures to get spare parts from suppliers within just a few hours after ordering. To fulfill these criteria corporations have to be located in the same area increasing their market and service for large corporations.

7. Capital: By looking at capital as a location condition, it is important to distinguish the physiology of fixed capital in buildings and equipment from financial capital. Fixed capital costs as building and construction costs vary from region to region. But on the other hand buildings can also be rented and existing plants can be expanded. Financial capital is highly mobile and does not very much influence decisions. For example, large Multinational Corporations such as Coca_Cola operate in many different countries and can raise capital where interest rates are lowest and conditions are most suitable.

Capital becomes a main factor when it comes to venture capital. In that case young, fast growing (or not) high tech firms are concerned which usually have not many fixed assets. These firms particularly need access to financial capital and also skilled educated employees.

Uncontrollable Factors

1. Government policy: The policies of the state governments and local bodies concerning labour laws, building codes, safety, etc., are the factors that demand attention. In order to have a balanced regional growth of industries, both central and state governments in

our country offer the package of incentives to entrepreneurs in particular locations. The incentive package may be in the form of exemption from a safes tax and excise duties for a specific period, soft loan from financial institutions, subsidy in electricity charges and investment subsidy. Some of these incentives may tempt to locate the plant to avail these facilities offered.

2. Climatic conditions: The geology of the area needs to be considered together with climatic conditions (humidity, temperature). Climates greatly influence human efficiency and behaviour. Some industries require specific climatic conditions e.g., textile mill will require humidity.

3. Supporting industries and services: Now a day the manufacturing organization will not make all the components and parts by itself and it subcontracts the work to vendors. So, the source of supply of component parts will be the one of the factors that influences the

location. The various services like communications, banking services professional consultancy services and other civil amenities services will play a vital role in selection of a location.

4. Community and labour attitudes: Community attitude towards their work and towards the prospective industries can make or mar the industry. Community attitudes towards supporting trade union activities are important criteria. Facility location in specific location is not desirable even though all factors are favouring because of labour attitude towards management, which brings very often the strikes and lockouts.

5. Community infrastructure and amenity: All manufacturing activities require access to a community infrastructure, most notably economic overhead capital, such as roads, railways, port facilities, power lines and service facilities and social overhead capital like schools, universities and hospitals.

These factors are also needed to be considered by location decisions as infrastructure is enormously expensive to build and for most manufacturing activities the existing stock of infrastructure provides physical restrictions on location possibilities.

2 Specific Locational Factors for Manufacturing Organisation

Dominant Factors

Factors dominating location decisions for new manufacturing plants can be broadly classified in six groups. They are listed in the order of their importance as follows.

1. Favorable labour climate

2. Proximity to markets

3. Quality of life

4. Proximity to suppliers and resources

5. Utilities, taxes, and real estate costs

1. Favorable labour climate: A favorable labour climate may be the most important factor in location decisions for labour-intensive firms in industries such as textiles, furniture, and consumer electronics. Labour climate includes wage rates, training requirements, attitudes toward work, worker productivity, and union strength. Many executives consider weak unions oral low probability of union organizing efforts as a distinct advantage.

2. Proximity to markets: After determining where the demand for goods and services is greatest, management must select a location for the facility that will supply that demand. Locating near markets is particularly important when the final goods are bulky or heavy and

outbound transportation rates are high. For example, manufacturers of products such as plastic pipe and heavy metals all emphasize proximity to their markets.

3. Quality of life: Good schools, recreational facilities, cultural events, and an attractive lifestyle contribute to quality of life. This factor is relatively unimportant on its own, but it can make the difference in location decisions.

4. Proximity to suppliers and resources: In many companies, plants supply parts to other facilities or rely on other facilities for management and staff support. These require frequent coordination and communication, which can become more difficult as distance increases.

5. Utilities, taxes, and real estate costs: Other important factors that may emerge include utility costs (telephone, energy, and water), local and state taxes, financing incentives offered by local or state governments, relocation costs, and land costs.

Secondary Factors There are some other factors needed to be considered, including room for expansion, construction costs, accessibility to multiple modes of transportation, the cost of shuffling people and materials between plants, competition from other firms for the workforce, community attitudes, and many others. For global operations, firms are emphasizing local employee skills and education and the local infrastructure.

10.7 SPECIFIC LOCATIONAL FACTORS FOR SERVICE ORGANISATION

Dominant Factors

The factors considered for manufacturers are also applied to service providers, with one important addition — the impact of location on sales and customer satisfaction. Customers usually look about how close a service facility is, particularly if the process requires considerable customer contact.

Proximity to Customers

Location is a key factor in determining how conveniently customers can carry on business with a firm. For example, few people would like to go to remotely located dry cleaner or supermarket if another is more convenient. Thus the influence of location on revenues tends to be the dominant factor.

Transportation Costs And Proximity To Markets

For warehousing and distribution operations, transportation costs and proximity to markets are extremely important. With a warehouse nearby, many firms can hold inventory closer to the customer, thus reducing delivery time and promoting sales.

Location of Competitors

One complication in estimating the sales potential at different location is the impact of competitors.

Management must not only consider the current location of competitors but also try to anticipate their reaction to the firm’s new location. Avoiding areas where competitors are already well established often pays. However, in some industries, such as new-car sales showrooms and fast food chains, locating near competitors is actually advantageous. The strategy is to create a critical mass, whereby several competing firms clustered in one location attract more customers than the total number who would shop at the same stores at scattered locations. Recognizing this effect, some firms use a follow –the leader strategy when selecting new sites.

Secondary Factors

Retailers also must consider the level of retail activity, residential density, traffic flow, and site visibility. Retail activity in the area is important, as shoppers often decide on impulse to go shopping or to eat in a restaurant. Traffic flows and visibility are important because businesses’ customers arrive in cars. Visibility involves distance from the street and size of nearby buildings and signs. High residential density ensures nighttime and weekend business when the population in the area fits the firm’s competitive priorities and target market segment.

10.8 LOCATION THEORIES

ALFRED WEBER’S THEORY OF THE LOCATION OF INDUSTRIES

Alfred Weber (1868–1958), with the publication of Theory of the Location of Industries in 1909, put forth the first developed general theory of industrial location. His model took into account several spatial factors for finding the optimal location and minimal cost for manufacturing plants.

The point for locating an industry that minimizes costs of transportation and labour requires analysis of three factors:

1. The point of optimal transportation based on the costs of distance to the ‘materialindex’—the ratio of weight to intermediate products (raw materials) to finished product.

2. The labour distortion, in which more favorable sources of lower cost of labour may justify greater transport distances.

3. Agglomeration and degglomerating.

Agglomeration or concentration of firms in a locale occurs when there is sufficient demand for support services for the company and labour force, including new investments in schools and hospitals. Also supporting companies, such as facilities that build and service machines and financial services, prefer closer contact with their customers.

Degglommeration occurs when companies and services leave because of over concentration of industries or of the wrong types of industries, or shortages of labour, capital, affordable land, etc. Weber also examined factors leading to the diversification of an industry in the horizontal relations between processes within the plant. The issue of industry location is increasingly relevant to today’s global markets and transnational corporations. Focusing only on the mechanics of the Weberian model could justify greater

transport distances for cheap labour and unexploited raw materials. When resources are exhausted or workers revolt, industries move to different countries.

10.9 LOCATION MODELS

Various models are available which help to identify the ideal location. Some of the popular models are:

1. Factor rating method

2. Weighted factor rating method

3. Load-distance method

4. Centre of gravity method

5. Break even analysis

1 Factor Rating Method

The process of selecting a new facility location involves a series of following steps:

1. Identify the important location factors.

2. Rate each factor according to its relative importance, i.e., higher the ratings is indicative of prominent factor.

3. Assign each location according to the merits of the location for each factor.

4. Calculate the rating for each location by multiplying factor assigned to each location with basic factors considered.

5. Find the sum of product calculated for each factor and select best location having highest total score.

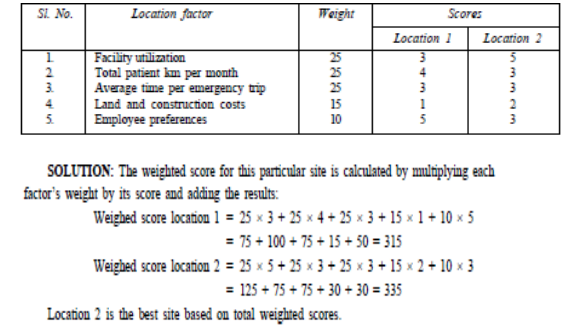

ILLUSTRATION 1: Let us assume that a new medical facility, Health-care, is to be located in Delhi. The location factors, factor rating and scores for two potential sites are shown in the following table. Which is the best location based on factor rating method?

The total score for location 2 is higher than that of location 1. Hence location 2, is the best choice.

2 Weighted Factor Rating Method

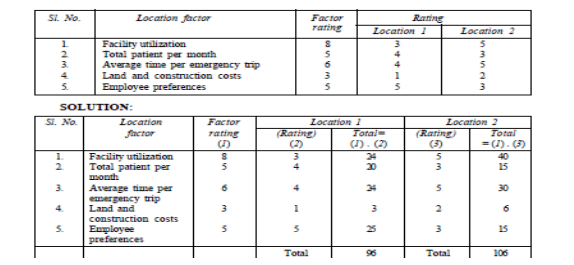

In this method to merge quantitative and qualitative factors, factors are assigned weights based on relative importance and weightage score for each site using a preference matrix is calculated. The site with the highest weighted score is selected as the best choice.

ILLUSTRATION 2: Let us assume that a new medical facility, Health-care, is to be located in Delhi. The location factors, weights, and scores (1 = poor, 5 = excellent) for two potential sites are shown in the following table. What is the weighted score for these sites? Which is the best location?