CHAPTER SEVEN: PRODUCTION CONTROL:

7.1 INTRODUCTION TO PRODUCTION PLANNING AND CONTROL

Production planning and control is a tool available to the management to achieve the stated objectives. Thus, a production system is encompassed by the four factors. i.e., quantity, quality, cost and time. Production planning starts with the analysis of the given data, i.e., demand for products, delivery schedule etc., and on the basis of the information available, a scheme of utilization of firms resources like machines, materials and men are worked out to obtain the target in the most economical way.

Once the plan is prepared, then execution of plan is performed in line with the details given in the plan. Production control comes into action if there is any deviation between the actual and planned. The corrective action is taken so as to achieve the targets set as per plan by using control techniques. Thus production planning and control can be defined as the “direction and coordination of firms’ resources towards attaining the prefixed goals.” Production planning and control helps to achieve uninterrupted flow of materials through production line by making available the materials at right time and required quantity.

7.3 NEED FOR PRODUCTION PLANNING AND CONTROL

The present techno-economic scenario of India emphasize on competitiveness in manufacturing.

Objectives of the topic:

a) Introduction and Meaning of production control.

b) Need for Production Planning and Control

c) Objectives of Production planning and control

d) Phases of Production Planning and control

e) Functions of Production Planning and control

Indian industries have to streamline the production activities and attain the maximum utilization of firms’ resources to enhance the productivity. Production planning and control serves as a useful tool to coordinate the activities of the production system by proper planning and control system. Production system can be compared to the nervous system with PPC as a brain.

Production planning and control is needed to achieve:

1. Effective utilization of firms’ resources.

2. To achieve the production objectives with respect to quality, quantity, cost and timeliness of delivery.

3. To obtain the uninterrupted production flow in order to meet customers varied demand with respect to quality and committed delivery schedule.

4. To help the company to supply good quality products to the customer on the continuous basis at competitive rates.

Production planning is a pre-production activity. It is the pre-determination of manufacturing requirements such as manpower, materials, machines and manufacturing process. Ray wild defines “Production planning is the determination, acquisition and arrangement of all facilities necessary for future production of products.” It represents the design of production system. Apart from planning the resources, it is going to organize the production. Based on the estimated demand for company’s products, it is going to establish the production programme to meet the targets set using the various resources.

Production Control

In spite of planning to the minute details, most of the time it is not possible to achieve production 100 per cent as per the plan. There may be innumerable factors which affect the production system and because of which there is a deviation from the actual plan. Some of the factors that affect are:

1. Non-availability of materials (due to shortage, etc.);

2. Plant, equipment and machine breakdown;

3. Changes in demand and rush orders;

4. Absenteeism of workers; and

5. Lack of coordination and communication between various functional areas of business.

Thus, if there is a deviation between actual production and planned production, the control function comes into action. Production control through control mechanism tries to take corrective action to match the planned and actual production. Thus, production control reviews the progress of the work, and takes corrective steps in order to ensure that programmed production takes place. The essential steps in control activity are:

1. Initiating the production,

2. Progressing, and

3. Corrective action based upon the feedback and reporting back to the production planning.

7.5 OBJECTIVES OF PRODUCTION PLANNING AND CONTROL

Following are the objectives of production planning and control:

1. Systematic planning of production activities to achieve the highest efficiency in production of goods/services.

2. To organize the production facilities like machines, men, etc., to achieve stated production objectives with respect to quantity and quality time and cost.

3. Optimum scheduling of resources.

4. Coordinate with other departments relating to production to achieve regular balanced and uninterrupted production flow.

5. To conform to delivery commitments.

6. Materials planning and control.

7. To be able to make adjustments due to changes in demand and rush orders.

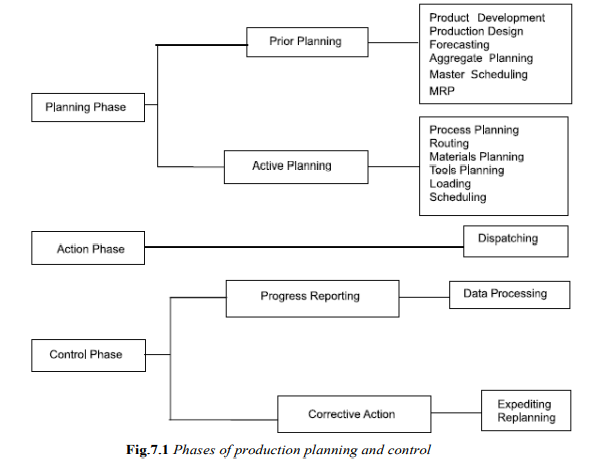

7.6 PHASES OF PRODUCTION PLANNING AND CONTROL

Production planning and control has three phases namely:

A. Planning Phase

B. Action Phase

C. Control Phase

A. Planning Phase

Planning is an exercise of intelligent anticipation in order to establish how an objective can be achieved or a need fulfilled in circumstances, which are invariably restrictive. Production planning determines the optimal schedule and sequence of operations economic batch quantity, machine assignment and dispatching priorities for sequencing.

It has two categories of planning namely

1. Prior planning

2. Active planning.

PRIOR PLANNING Prior planning means pre-production planning. This includes all the planning efforts, which are taking place prior to the active planning.

Modules of pre-planning

The modules of prior planning are as follows:

1. Product development and design is the process of developing a new product with all the features, which are essential for effective use in the field, and designing it accordingly. At the design stage, one has to take several aspects of design like, design for selling, design for

manufacturing and design for usage.

2. Forecasting is an estimate of demand, which will happen in future. Since, it is only an estimate based on the past demand, proper care must be taken while estimating it. Given the sales forecast, the factory capacity, the aggregate inventory levels and size of the work force, the manager must decide at what rate of production to operate the plant over an intermediate

planning horizon.

3. Aggregate planning aims to find out a product wise planning over the intermediate planning horizon.

4. Material requirement planning is a technique for determining the quantity and timing for the acquisition of dependent items needed to satisfy the master production schedule.

ACTIVE PLANNING The modules of active planning are: Process planning and routing,

Materials planning. Tools planning, Loading, Scheduling etc.

1. Process planning and routing is a complete determination of the specific technological process steps and their sequence to produce products at the desired quality, quantity and cost. It determines the method of manufacturing a product selects the tools and equipments, analyses how the manufacturing of the product will fit into the facilities. Routing in particular prescribes the flow of work in the plant and it is related to the considerations of layout, temporary locations for raw materials and components and materials handling systems.

2. A material planning is a process which determines the requirements of various raw materials/subassemblies by considering the trade-off between various cost components like, carrying cost, ordering cost, shortage cost, and so forth.

3. Tools’ planning determines the requirements of various tools by taking process specification (surface finish, length of the job, overall depth of cut etc.), material specifications (type of material used, hardness of the material, shape and size of the material etc.) and equipment specifications (speed range, feed range, depth of cut range etc.).

4. Loading is the process of assigning jobs to several machines such that there is a load balance among the machines. This is relatively a complex task, which can be managed with the help of efficient heuristic procedures.

5. Scheduling is the time phase of loading and determines when and in what sequence the work will be carried out. This fixes the starting as well as the finishing time for each job.

B. Action Phase

Action phase has the major step of dispatching. Dispatching is the transition from planning phase to action phase. In this phase, the worker is ordered to start manufacturing the product. The tasks which are included in dispatching are job order, store issue order, tool order, time ticket, inspection order, move order etc. The job order number is the key item which is to be mentioned in all other reports/orders. Stores issue order gives instruction to stores to issue materials for manufacturing the product as per product specifications. As per tooling requirements for manufacturing the product, the tool order instruct the tool room to issue necessary tools. Time ticket is nothing but a card which is designed to note down the actual time taken at various processes. This information is used for

deciding the costs for future jobs of similar nature and also for performing variance analysis, which helps to exercise control.

Job order is the official authorization to the shop floor to start manufacturing the product. Generally, the process sequence will contain some testing and inspection. So, these are to be instructed to inspection wing in the form of inspection order for timely testing and inspection so that the amount of rework is minimized. The manufacture of product involves moving raw materials/subassemblies to the main line. This is done by a well-designed materials handling system. So, proper instruction is given to the materials handling facilities for major movements of materials/subassemblies in the form of a move order. Movements which involve less distance and fewer loads are managed at the shop floor level based on requests from operators.

C. Control Phase

The control phase has the following two major modules:

1. Progress reporting, and

2. Corrective action.

1. Progress Reporting

In progress reporting, the data regarding what is happening with the job is collected. Also, it helps to make comparison with the present level of performance. The various data pertaining to materials rejection, process variations, equipment failures, operator efficiency, operator absenteeism, tool life, etc., are collected and analyzed for the purpose of progress reporting. These data are used for performing variance analysis, which would help us to identify critical areas that deserve immediate attention for corrective actions.

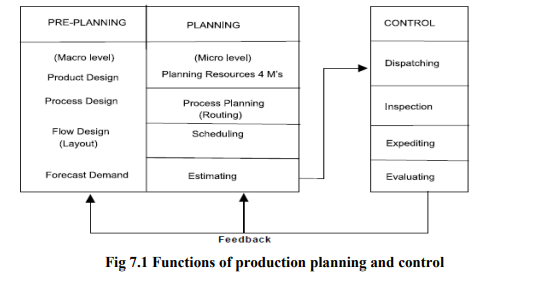

7.7 FUNCTIONS OF PRODUCTION PLANNING AND CONTROL

Functions of production planning and controlling is classified into:

1. Pre-planning function

2. Planning function

3. Control function

The functions of production planning and controlling are depicted in the Fig. 5.2.

1. PRE-PLANNING FUNCTION

Pre-planning is a macro level planning and deals with analysis of data and is an outline of the planning policy based upon the forecasted demand, market analysis and product design and development. This stage is concerned with process design (new processes and developments, equipment policy and replacement and work flow (Plant layout). The pre-planning function of PPC is concerned with decision-making with respect to methods, machines and work flow with respect to availability, scope and capacity.

2. PLANNING FUNCTION

The planning function starts once the task to be accomplished is specified, with the analysis of four M’s, i.e., Machines, Methods, Materials and Manpower. This is followed by process planning (routing). Both short-term (near future) and long-term planning are considered. Standardization, simplification of products and processes are given due consideration.

3. CONTROL FUNCTION

Control phase is effected by dispatching, inspection and expediting materials control, analysis of work-in-process. Finally, evaluation makes the PPC cycle complete and corrective actions are taken through a feedback from analysis. A good communication, and feedback system is essential to enhance and ensure effectiveness of PPC.

7.8 ROUTING

Routing may be defined as the selection of path which each part of the product will follow while being transformed from raw materials to finished products. Path of the product will also give sequence of operation to be adopted while being manufactured. In other way, routing means determination of most advantageous path to be followed from department to department and machine to machine till raw material gets its final shape, which involves the following steps:

(a) Type of work to be done on product or its parts.

(b) Operation required to do the work.

(c) Sequence of operation required.

(d) Where the work will be done.

(e) A proper classification about the personnel required and the machine for doing the work.

For effective production control of a well-managed industry with standard conditions, the routing plays an important role, i.e., to have the best results obtained from available plant capacity. Thus routing provides the basis for scheduling, dispatching and follow-up.

Techniques of Routing

While converting raw material into required goods different operations are to be performed and the selection of a particular path of operations for each piece is termed as ‘Routing’. This selection of a particular path, i.e. sequence of operations must be the best and cheapest to have the lowest cost of the final product. The various routing techniques are:

1. Route card: This card always accompanies with the job throughout all operations. This indicates the material used during manufacturing and their progress from one operation to another. In addition to this the details of scrap and good work produced are also recorded.

2. Work sheet: It contains

(a) Specifications to be followed while manufacturing.

(b) Instructions regarding routing of every part with identification number of machines and work place of operation.

This sheet is made for manufacturing as well as for maintenance.

3. Route sheet: It deals with specific production order. Generally made from operation sheets.

One sheet is required for each part or component of the order. This includes the following:

(a) Number and other identification of order.

(b) Symbol and identification of part.

(c) Number of pieces to be made.

(d) Number of pieces in each lot—if put through in lots.

(e) Operation data which includes:

(i) List of operation on the part.

(ii) Department in which operations are to be performed.

(iii) Machine to be used for each operation.

(iv) Fixed sequence of operation, if any.

(f) Rate at which job must be completed, determined from the operation sheet.

4. Move order: Though this is document needed for production control, it is never used for routing system. Move order is prepared for each operation as per operation sheet. On this the quantity passed forward, scrapped and to be rectified are recorded. It is returned to planning office when the operation is completed.

REVIEW QUESTION

i. What do you mean by production planning and control?

ii. Why do you need production planning and control?

iii. What are the objective of production planning and control?

iv. Discuss the phases of production planning?

v. Explain the techniques of routing