Many companies attempt to track down new technologies and product through systematic market research. The results of this research are usually translated by the marketing department into several new products idea which are then discussed with research and development and the engineering department. These discussions are often the starting point for projects aimed at improving current products or the developments of new ones.

The process of new product development

Depending on the nature of the product and the type of company the development process, starting with conceptualization and ending with introduction to the market will pass through several stages

- Products development. In this phase the idea supplied by the marketing department are translated into a few concrete, but still relatively abstract. Functional design. Such designs describe the functions that the product to be developed will have to fulfill for the user. From these functional designs, the most promising design is selected to be elaborated further.

- Product design. In this phase the functional design is worked out in detail – proposals are made about the materials to be used. The physical properties that the product must satisfy. E t c. Often several products designs are produced which meet the functional design and these can be presented to potential clients at an early stage. In order to get the first reaction and impressions concept testing. This information enables the engineers to focus on the most promising design. Subsequently the product design is elaborated in the form of prototype can also be presented to potential buyers and users.

- Production planning. The manufacturability of the product has already been considered during the product design stage the production requirements are taken into account. After the prototype has been approved. Preparation for production can be started. If it concerns a technically complex products this phase may take a lot of time and it may be necessary to purchase new production equipment. The capacity requirements of this new equipment will have to be determined based on. Among other things, Market exploration and sale forecasts. Production planning frequently ends with a number of production series

- Start of the production. Products from the pre production series are subjected to through examination: based on the result of this examination the product design or the setting of the machines might be adopted so as to limit future production and quality problems to a minimum. One of the problems that might occur in this phase is changing the specifications. Every change is documented in a change – order send by the engineering department to the purchasing department in order to discuss this with the supplier. This phase means a lot of work for the purchaser involved in the project.

Every change in the specification has to be approved by the supplier, the consequences for the total costs have to be analyzed, the change product needs to be tested again, etc. This is one of the reason why it takes so long for a new product to become available for customers. Only when the problem have been taken care of, can actual production commence. It goes without saying it is possible to refine this sequence of steps, depending on the nature of the product and the type of company. As the development process advances, the specifications become more rigid and it becomes more difficult to introduce changes. The consequence for purchasing is

that its latitude decreases and the cost of technical changes introduces at a later stage in the process become higher.

Once a suitable material or construction has been found, tested and approved, the willingness to consider any alternatives (in the form of a different material, component or a substitute product from another supplier) will be limited at a later stage. Any alternative will have to be tested and approved again, which implies not only a lot of work but also risks. This desire to reduce technical risk may result in specific components being channeled in the direction of one particular supplier because of positive experiences with this supplier in the past.

The buyer is put in a difficult situation since it is awkward to negotiate with such suppliers. Based on his job perceptions, a buyer will always attempt to have more than one supplier to fall back on. For the buyer to go out into the market, the product preferably must be described in terms of functional specifications rather than in terms of supplier or brand specifications. There exists therefore, a kind of natural conflicts in the way the engineers and buyers operate which can only be solved by cross functional development teams.

Communications between buyers and first tier suppliers

Large manufacturers communicate with their first tier suppliers in product development as follows:

- Purchasing engineering. This is a specialist function to provide the liaison between the engineering department and the purchasing department. Purchasing engineers are members of the design teams, where they will evaluate designs against purchasing-specific criteria. It is their task to bring in specific supply market knowledge and new supplier at an early stage of design.

- Early supplier involvement (ESI) suppliers who have proved in the past to be ‘best-inclass’ are invited to participate in the company’s development projects at an early stage. In this way they are able to criticize future designs, suggest alternative materials, come up with ideas for more efficient manufacturing, etc as a stage where engineering changes can be made without severe cost consequences.

- Residential engineering. A next step is to co-locate engineers from the suppler on a more or less permanent basis within the organization in order to work on design or.

benefits of early supplier involvement

In accessing the benefits of early supplier involvement, companies need to differentiate between short-term and long-term benefits (Van Echtelt, 2004). Short-term benefits may result from improved product quality, reduction of product cost, reduction of development time and reduction of development cost. These benefits result from the supplier’s in-depth knowledge of components and technologies, which enables them to match component designs better with their manufacturing capabilities.

Long-term benefits may consist of more efficient and effective collaboration in future new product development projects, the alignment of future technology strategies, a better access to the technology resources of the supplier and the contribution of suppliers to product differentiation. Involving buyers in development processes at an early stage can result in contribution of new

knowledge and better understanding of:

- Construction

- Suitable materials

- Suppliers

- Supplier knowledge

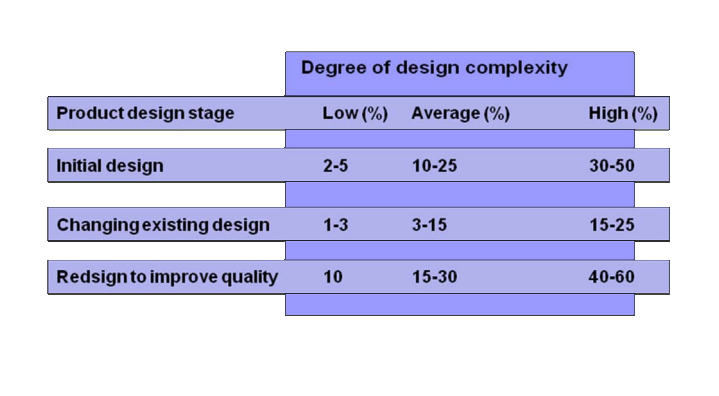

Involving the supplier in new product development can also result in considerable savings. The following shows the degree of design complexities with each of product design stage.