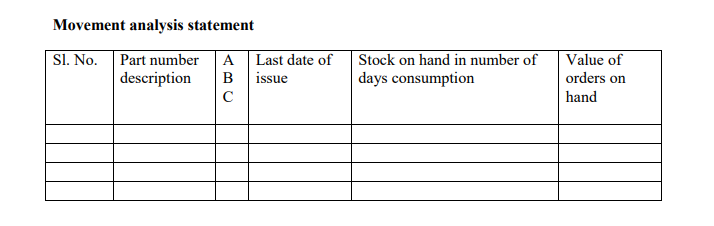

The combing process of combining the stock records and movement analysis has been found very effective in locating such stocks in the total inventory. Stock issue cards should be combed and items which have not been consumed (non-moving) for a period of one year must be isolated. A list of such items and their value in terms of money and time must be made. Similarly, such lists must be prepared for items which have not moved for 2 years, 3 years, and 5 years and above. Such lists can then be put up to top management for disposal action. Care must be taken to prepare a separate list of imported spares and insurance items.

Whenever changes in production programme, design and product lines are contemplated, a senior executive from materials management must definitely be kept in the picture. This helps in several ways. He is in a position to inform top management of the amount of stock of materials on hand that are likely to be rendered obsolete if and when the changes are introduced. This could even guide the management as to when the changes could be made so that the existing stock can be consumed in full. The materials manager in turn can freeze further orders for such materials and try to negotiate with the suppliers to take back the stock.

For some items he can introduce the buy-back clause wherein the suppliers takes back items not consumed within a specific period. For new items which may be required, he can try to develop sources and place orders so that changes can be expeditiously introduced. All this highlights that a close coordination is required in order to avoid stock piling obsolete and surplus items. Selective control based on ABC analysis, accurate forecasting techniques and proper preservation minimise such accumulation. In the case of storage of perishable items the Central Warehousing Corporation has devised a scheme to enlarge its scope to cover certain specialized lines of storage. The schemes drawn up by the corporation include setting up a chain of cold storage plants for potatoes, and fruit, and storage facilities for certified seeds.

Many organizations have introduced formal documentation in introducing changes in design or product. It is called the ‗Effective Point Advice.‘ This is popularly known as EPA. Here, the proposed changes, details of new materials and products required, details of materials and the products which will be invalid/obsolete when the change occurs and the approximate date when the change is expected to be introduced are detailed and circulated to concerned departments.

EPA thereby helps in tapering off the stocks of ‗invalid‘ items, cancellation of orders for such items, placing orders for buying and/or manufacturing new items and related activities. EPA systems help in better coordination for profitable introduction of changes with minimum ‗side effects‘ such as the accumulation of obsolete items. The reclamation of scrap has not attracted the attention of the top management in Indian Industry. Optimal utilization of scrap would allow conservation of the use of scarce natural resources, such as iron ore. This is because scrap is an important element which goes into the manufacture of steel and castings. It is possible to salvage scrap for usage within the firm in some cases.

Press parts are normally made from sheets and plates. The off-cuts generated during such process can be profitably utilized in making smaller press components such as washers. Rationalizing the supply size, changes in process such as reversing the dies may result in minimization of scrap. Big organizations have a full-fledged scrap salvaging department. These departments segregate the scrap into categories, like turnings, borings, plate cuttings, end pieces of billets, punching etc. Colour coding the scrap is also done to avoid the mixing of different categories of scrap. It is also advantageous to the end-users in each category and supply of scrap at the appropriate time for production. Often informing the production department at the right time about the volume of scrap generated enables prevention of excessive scrap through timely changes in production methods, tooling and materials.