CHAPTER FIVE: CAPACITY PLANNING:

5.1 CAPACITY PLANNING

Design of the production system involves planning for the inputs, conversion process and outputs of production operation. The effective management of capacity is the most important responsibility of production management. The objective of capacity management (i.e., planning and control of capacity) is to match the level of operations to the level of demand. Capacity planning is to be carried out keeping in mind future growth and expansion plans, market trends, sales forecasting, etc. It is a simple task to plan the capacity in case of stable

demand. But in practice the demand will be seldom stable. The fluctuation of demand creates problems regarding the procurement of resources to meet the customer demand. Capacity decisions are strategic in nature. Capacity is the rate of productive capability of a facility. Capacity is usually expressed as volume of output per period of time. Production managers are more concerned about the capacity for the following reasons:

Sufficient capacity is required to meet the customers demand in time.

Capacity affects the cost efficiency of operations.

Capacity affects the scheduling system.

Capacity creation requires an investment.

Capacity planning is the first step when an organization decides to produce more or new products.

OBJECTIVES OF THE STUDY:

a) Understand, appreciate and explain the importance of capacity planning.

b) Discuss ways of defining and measuring capacity.

c) Describe the factors that determine effective capacity alternatives.

d) Discuss the major considerations related to developing capacity alternatives.

An Operations Manager is supposed to identify tactics and formulate a strategy in order to answer the basic questions with respect to capacity handling. These questions are:

1. What kind of capacity is needed?

2. How much is needed?

3. When is it needed?

Importance of Capacity Decisions

Capacity decisions impacts ability to meet future demands, affects operating costs. These decisions often act as a major determinant of initial costs, as they involve long-term commitment. These decisions affect competitiveness and gives ease of management. Capacity

Decisions focus on globalization as it is more complex and impacts long range planning.

1. Ability to meet future demands.

Capacity essentially limits the rate of possible output.Having capacity to satisfy demand can allow a company of taking advantage of tremendous opportunities. An international automobile manufacturer of good repute increased its production by working on its capacity decision after its quality product received a lot more demand than it was originally anticipated.

2. Affects operating costs.

We already know that estimated or forecasted demand differs from actual demand, so the ideal concept of capacity matching demand is untrue. Organizations should be willing to take a critical decision to balance the cost of over and under capacity. Overcapacity reflects overkill of resources and under capacity shows a weak management philosophy to make best use of an available market.

3. Acts as a major determinant of initial costs.

It is typical to see that greater the capacity of a productive unit, greater would be the cost. This does not mean I am advocating a one to one relationship for higher capacity for production to costs; in fact larger units tend to cost proportionately less than smaller units. E.g. Pakistan Steel

Mill at Karachi is one good example, where higher costs are misunderstood as the mills capacity is not being fully utilized

4. Involves long-term commitment.

Once long term commitment of resources have been taken, the difficulty of reversing would cost more. Indicating a capacity increase or decrease for an organization set up would mean

additional costs.

5. Affects competitiveness.

This is very critical, if a firm has an excessive capacity or can quickly add capacity, which fact may serve as a barrier against entry by other firms.

6. Affects ease of management.

Capacity increase or decrease decisions involves management to answer the question of operating the organization as well as an increase or decrease in the plant capacity

7. Globalization adds complexity.

Capacity decision often involves making a decision in a foreign country which requires the management to know about the political, economic and cultural issues.

8. Impacts long range planning.

Capacity decisions extend beyond 18 months and thus get classified as long term in nature.

5.2 MEASUREMENT OF CAPACITY PLANNING

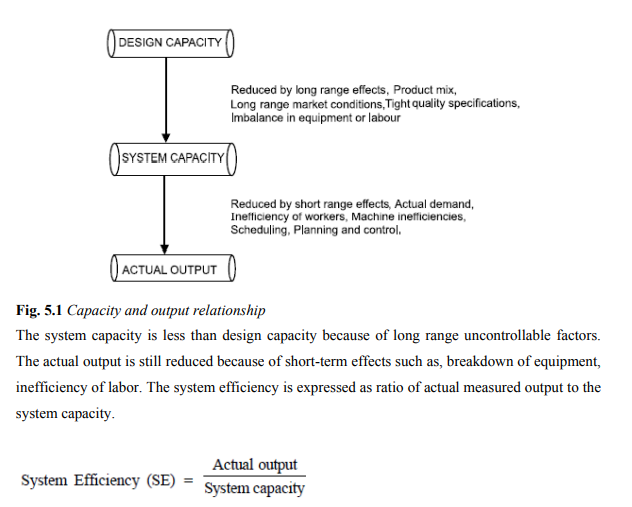

The capacity of the manufacturing unit can be expressed in number of units of output per period. In some situations measuring capacity is more complicated when they manufacture multiple products. In such situations, the capacity is expressed as man-hours or machine hours. The relationship between capacity and output is shown in Fig. 5.6. Design capacity: Designed capacity of a facility is the planned or engineered rate of output of goods or services under normal or full scale operating conditions. For example, the designed capacity of the cement plant is 100 TPD (Tonnes per day). Capacity of the sugar factory is 150 tonnes of sugarcane crushing per day.

System capacity: System capacity is the maximum output of the specific product or product mix the system of workers and machines is capable of producing as an integrated whole. System capacity is less than design capacity or at the most equal, because of the limitation of

product mix, quality specification, breakdowns. The actual is even less because of many factors affecting the output such as actual demand, downtime due to machine/equipment failure, unauthorized absenteeism.

4. Installed capacity: The capacity provided at the time of installation of the plant is called installed capacity.

5. Rated capacity: Capacity based on the highest production rate established by actual trials is referred to as rated capacity.

5.3 PROCESS OF CAPACITY PLANNING

Capacity planning is concerned with defining the long-term and the short-term capacity needs of an organization and determining how those needs will be satisfied. Capacity planning decisions are taken based upon the consumer demand and this is merged with the human, material and financial resources of the organization. Capacity requirements can be evaluated from two perspectives—long-term capacity strategies and short-term capacity strategies.

1. LONG-TERM CAPACITY STRATEGIES

Long-term capacity requirements are more difficult to determine because the future demand and technology are uncertain. Forecasting for five or ten years into the future is more risky and difficult. Even sometimes company’s today’s products may not be existing in the future. Long range capacity requirements are dependent on marketing plans, product development and lifecycle of the product. Long-term capacity planning is concerned with accommodating major changes that affect overall level of the output in long-term. Marketing environmental assessment and implementing the long-term capacity plans in a systematic manner are the major responsibilities of management. Following parameters will affect long range capacity decisions.

1. Multiple products: Company’s produce more than one product using the same facilities in order to increase the profit. The manufacturing of multiple products will reduce the risk of failure. Having more than one product helps the capacity planners to do a better job. Because products are in different stages of their life-cycles, it is easy to schedule them to get maximum

capacity utilisation.

2. Phasing in capacity: In high technology industries, and in industries where technology developments are very fast, the rate of obsolescence is high. The products should be brought into the market quickly. The time to construct the facilities will be long and there is no much time as the products should be introduced into the market quickly. Here the solution is phase in capacity on modular basis. Some commitment is made for building funds and men towards facilities over a period of 3–5 years. This is an effective way of capitalising on technological breakthrough.

3. Phasing out capacity: The outdated manufacturing facilities cause excessive plant closures and down time. The impact of closures is not limited to only fixed costs of plant and machinery. Thus, the phasing out here is done with humanistic way without affecting the community. The phasing out options makes alternative arrangements for men like shifting them to other jobs or to other locations, compensating the employees, etc.

2. SHORT-TERM CAPACITY STRATEGIES

Managers often use forecasts of product demand to estimate the short-term workload the facility must handle. Managers looking ahead up to 12 months, anticipate output requirements for different products, and services. Managers then compare requirements with existing capacity and then take decisions as to when the capacity adjustments are needed. For short-term periods of up to one year, fundamental capacity is fixed. Major facilities will not be changed. Many short-term adjustments for increasing or decreasing capacity are possible. The adjustments to be required depend upon the conversion process like whether it is capital intensive or labour intensive or whether product can be stored as inventory. Capital intensive processes depend on physical facilities, plant and equipment. Short-term capacity can be modified by operating these facilities more or less intensively than normal. In labour intensive processes short-term capacity can be changed by laying off or hiring people or by giving overtime to workers. The strategies for changing capacity also depend upon how long

the product can be stored as inventory. The short-term capacity strategies are:

1. Inventories: Stock of finished goods during slack periods to meet the demand during peak

period.

2. Backlog: During peak periods, the willing customers are requested to wait and their orders are fulfilled after a peak demand period.

3. Employment level (hiring or firing): Hire additional employees during peak demand period and lay-off employees as demand decreases.

4. Employee training: Develop multi-skilled employees through training so that they can be rotated among different jobs. The multi-skilling helps as an alternative to hiring employees.

5. Subcontracting: During peak periods, hire the capacity of other firms temporarily to make the component parts or products.

6. Process design: Change job contents by redesigning the job.

Strategy Formulation With respect to Capacity Planning

1. Capacity strategy for long-term demand which focus on demand patterns and takes into account growth rate and variability

2. Facilities that focus on cost of building and operating

3. Technological changes relate to rate and direction of technology changes

4. Behavior of competitors

5. Availability of capital and other inputs

Key Decisions of Capacity Planning

It is important to identify the key decisions in order to carry out a correct capacity planning decision.

Some of the common key decisions are

1. Amount of capacity needed

2. Timing of changes

3. Need to maintain balance

4. Extent of flexibility of facilities

Steps for Capacity Planning Strategy

It is important to understand how to formulate a capacity planning strategy

1. Estimate future capacity requirements

2. Evaluate existing capacity

3. Identify alternatives

4. Conduct financial analysis

5. Assess key qualitative issues

6. Select one alternative

7. Implement alternative chosen

8. Monitor results

5.4 ROUTING

Routing may be defined as the selection of path which each part of the product will follow while being transformed from raw materials to finished products. Path of the product will also give sequence of operation to be adopted while being manufactured.

In other way, routing means determination of most advantageous path to be followed from department to department and machine to machine till raw material gets its final shape, which involves the following steps:

(a) Type of work to be done on product or its parts.

(b) Operation required to do the work.

(c) Sequence of operation required.

(d) Where the work will be done.

(e) A proper classification about the personnel required and the machine for doing the work.

For effective production control of a well-managed industry with standard conditions, the routing plays an important role, i.e., to have the best results obtained from available plant capacity. Thus routing provides the basis for scheduling, dispatching and follow-up.

Techniques of Routing While converting raw material into required goods different operations are to be performed and the selection of a particular path of operations for each piece is termed as ‘Routing’. This selection of a particular path, i.e. sequence of operations must be the best and cheapest to have the lowest cost of the final product. The various routing techniques are:

1. Route card: This card always accompanies with the job throughout all operations. This indicates the material used during manufacturing and their progress from one operation to another. In addition to this the details of scrap and good work produced are also recorded.

2. Work sheet: It contains

(a) Specifications to be followed while manufacturing.

(b) Instructions regarding routing of every part with identification number of machines and work

place of operation.

This sheet is made for manufacturing as well as for maintenance.

3. Route sheet: It deals with specific production order. Generally made from operation sheets.

One sheet is required for each part or component of the order. These includes the following:

(a) Number and other identification of order.

(b) Symbol and identification of part.

(c) Number of pieces to be made.

(d) Number of pieces in each lot—if put through in lots.

(e) Operation data which includes:

(i) List of operation on the part.

(ii) Department in which operations are to be performed.

(iii) Machine to be used for each operation.

(iv) Fixed sequence of operation, if any.

(f) Rate at which job must be completed, determined from the operation sheet.

4. Move order: Though this is document needed for production control, it is never used for routing system. Move order is prepared for each operation as per operation sheet. On this the quantity passed forward, scrapped and to be rectified are recorded. It is returned to planning office when the operation is completed.

REVIEW QUESTIONS

i. How do you measure capacity?

ii. Discuss the importance of Capacity Decisions.

iii. Explain the techniques of routing.

iv. What are the key decision of capacity planning

v. Briefly discuss the short-term