INTRODUCTION TO PROJECT QUALITY MANAGEMENT

Definition of terms

Quality

Quality is extremely hard to define, and it is simply stated: “Fit for use or purpose.” It is all about meeting the needs and expectations of customers with respect to functionality, design, reliability, durability, & price of the product

Quality management

Coordinated activities to direct and control an organization with regard to quality.

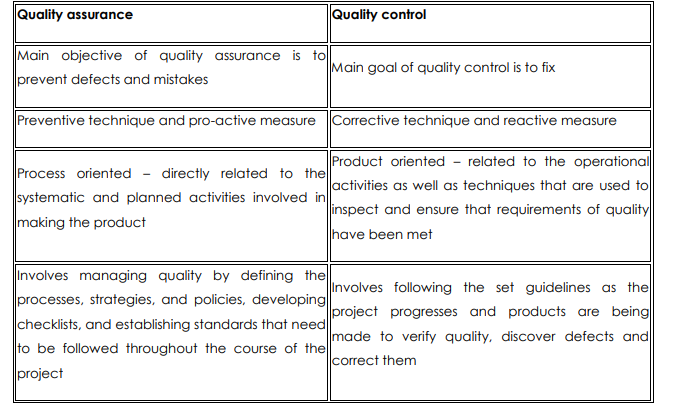

Difference between quality control and quality assurance

The key concepts of quality management

Produce goods or services that respond specifically to customer needs.

To ensure the survival of the company with profit obtained through quality.

Identify the most critical problems and solve them with the highest priority.

Talk to reason and make decisions based on factual data.

Administer the company throughout the process and not by its results.

Methodically reduce wastage by isolating the root causes.

The customer is king. Do not serve them without quality products.

Prevention should have the highest importance.

When using „trial and error‟ never allow a problem to repeat

Importance of quality management

1. It helps an organization achieve greater consistency in tasks and activities that are involved in the production of products and services.

2. It increases efficiency in processes, reduces wastage, and improves the use of time and other resources.

3. It helps improve customer satisfaction.

4. It enables businesses to market their business effectively and exploit new markets.

5. It makes it easier for businesses to integrate new employees, and thus helps businesses manage growth more seamlessly.

6. It enables a business to continuously improve their products, processes, and systems.

Historical background of quality management

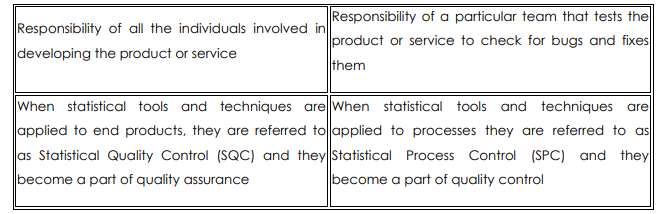

The concept of Quality Management has its origins in the work of statistician Walter Shewhart, who was conducting research on the analysis of industrial processes while working at Bell Laboratories in the early 20th century. Shewhart realized manufacturing processes produced data that he could measure and analyze to determine their conformity to ideal standards of stability and control, and he could apply remedies that would bring any deviations back into line. This revolutionary approach highlighted the advantage of process-centered applications of Quality over older product-centered approaches. This concept is now referred to as statistical quality control (SQC) and is the backbone of the initial exploration of Quality in manufacturing. In the 1940s, the Second World War prompted the American government to implement Quality standards based on SQC for military vendors. This improved

Quality in the short term, but most civilian manufacturers failed to incorporate process improvement throughout their organizations. After the war, engineers W. Edwards Deming and Joseph M. Juran worked as consultants in Japan as Japanese industry worked to recover from the war and transform their economy to focus on civilian production of goods and services. Deming and Juran

worked with Japanese manufacturers to create the concept of Total Quality, in which Quality extends beyond the manufacturing process to all organizational processes and instills the values of Quality in every worker. As a result of this Total Quality transformation, Japan became a manufacturing powerhouse, vastly increasing its market share at the expense of American manufacturers who had

yet to recognize the value of Total Quality. In the 1980s, American manufacturers and legislators began to recognize the

crises of poor Quality in American manufacturing. The American response, built on Deming‟s and Juran‟s work in Japan, was Total Quality Management (TQM).

The first ISO 9000 standard for Quality appeared in 1987, and it continues to be the globally recognized standard for Quality accreditation across many industries.

Since 2000, ISO 9000 has evolved to meet the needs of a changing marketplace. Globalization and emerging technologies have expanded both the scope of Quality and the tools used to meet Quality standards. New approaches, such as Six Sigma developed by Motorola, have achieved remarkable levels of productivity and variation reduction to produce goods and services that are free from defects. Quality is now seen as an approach that can be applied to any organization, including services, government, healthcare, education, and even nascent technology like Bitcoin and Blockchain.

The quality Gurus

Changing trends in quality management

Quality as a Way of Life for Businesses

Quality as a Way of Life for Businesses For your business, quality should not be only the responsibility of the quality department. It should be a way of life for all the people of all the designations working across functions in the company. Proper standard operating procedures (SOP) and checklists should be implemented, wherever required and wherever possible. Quality must be the core component of any process, project or function throughout the company and business.

2. Integrated Quality Approach

It is important to have an integrated, holistic and a centrally well-coordinated quality approach, encompassing all the functions and processes, as well as inter-function processes.

3. Strategic Role of Quality Department

Strategic Role of Quality Department Quality should play an important role at a

strategic level. As a business leader, you may consider introducing well coordinated and centrally monitored quality management initiatives such as lean principles or Six Sigma. However, it should not be done randomly, but in a well planned out manner. Priority processes should be identified and pilot project run to see the efforts required and the results achieved – in terms of improvement of processes, output quality, reduced efforts and costs, impact on revenue, etc.

4. Stringent Quality Standards across Value Chain.

Stringent Quality Standards across Value Chain It is not only important to enhance the quality management in your company, but also to partner with the competent suppliers and vendors, who have highest quality standards for their products and services. This shall provide you with the high quality input material and services, in line with the quality standards of your final products and services for your customers.

Quality management process

A Quality Management Process is a set of procedures that are followed to ensure that the deliverables produced by a team are “fit for purpose”. The start of the Quality Management Process involves setting quality targets, which are agreed with the customer. A “Quality Assurance Process” and “Quality Control Process” are then undertaken, to measure and report the actual quality of deliverables. As part of the Quality Management Process, any quality issues are identified and resolved quickly.

The four main components of a quality management process are Quality Planning, Quality Assurance, Quality Control and Continuous Improvement.

1. Quality Planning

Determines which quality standards are necessary and provides guidance to stakeholders on how quality management will be performed on the project. It will include: Stakeholder expectations – this section should document specifically what the customer expects in terms of project quality. Including whether they have specified any external quality standards and what their priorities are in terms of

the areas affected by quality. Success criteria (as defined in the business case) in addition to the defined success criteria this section should also define acceptable tolerances for achievement of those objectives. Standards applicable (internal and external) – the project environment may require that the Quality Plan incorporates the requirements of external

standards. These could range from the Company‟s own quality standards to ISO 9000 or Health and Safety at Work Legislation. Roles and responsibilities concerned with quality – these may include quality assurance testing, supervision and management roles

The process that will be followed – these will be documented in a systematic way and will govern the mechanisms for the product of the product

specifications and testing procedures.

How continuous improvement will be actioned – this may include making adjustments to processes where they are proven to be unsatisfactory.

Project assurance techniques – This section will describe how assurance will be performed and who is responsible. It will define policies of quality reviews and audits of the management process.

Quality control measures – will define control measures that will be used Interactions with other processes such as configuration management, change control and how these links will be established.

2. Quality Assurance

Quality reviews are a key tool for quality assurance but could also be used for quality control. The way they will be conducted will be set out in the Quality

Plan. Four overall objectives for review:

Provide assurance that the project is proceeding according to agreed plans/processes.

Measure effectiveness of agreed plans/processes

Capture lessons learned

Identify areas of non-compliance and opportunities for improvement

Quality Assurance covers the whole project lifecycle and is not concentrated on any particular phase. It ensures that the other processes (mainly Planning and Control) are being adequately performed and that the project is adhering to any corporate standards that are relevant to the project.

Quality Assurance involves pre-planned, regular reviews and independent audits to verify that work is being carried out consistently in accordance with defined procedures and to provide confidence to stakeholders the project will satisfy relevant quality requirements and standards.

3. Quality Control

Quality control consists of inspection, testing and quality measurement verifies that the projects deliverables conform to specification, is fit for purpose and meet stakeholder‟s expectations. Quality control techniques are varied and the technique used should be driven by the nature of the project. The most obvious example of quality control is the inspections and tests that are done to check

whether a product meets its specification. The exact inspection method used depends entirely on the technical nature of the product being developed by the project. Inspections that may be relevant:

Construction – part of Quality Control would be to check the strength of the concrete. Aircraft – part of Quality Control would be to check the quality of the welding·

Process – part of Quality Control may be to pilot before making live. Having inspected the products and gained the data on their performance, we need to identify any problems and understand the causes – tools that can be used to

display the inspection data are:

Histogram – plots frequency of variables. The height of the bar shows how often a particular result occurs and the number of bars indicates the range of results

Scatter Chart – used where there are 2 variable and we want to see if there is a relationship between them, i.e. the strength of number of cubes against recorded outside temperatures may show relationship between strength and temperature.

Control Chart – plots value for each of a number of outputs of the same process.

It also sets tolerances for the values measured. This allows us to identify if the process is in or out of control. For example plotting the results for the test of each weld on the ship to ensure our welding process was within acceptable control limits

Run Chart – plots the history of a single variable. For example if a key performance criterion for a project was the variance between actual and cost, this variable could be plotted over time to track its variation and identify trends.·

Tools for understanding causes or prioritising areas for action:

Pareto Chart – this is a type of histogram that orders the information in a particular way. This is sometime called the 80:20 rule; 80% of the observable faults are cause by 20% of the root causes. This enables us to direct problem solving where it will be most effective.

Process Control Chart – a graphical representation of a process showing activities and decision points. A flow is used to show how different parts of a system interrelate. It can help the project team identify where quality problems

may occur or redesign a process to correct problems.

Cause and Effect – is simply a graphical technique to help develop an understanding of how certain causes may lead to a particular effect. This section may also define how the project should control change and perform configuration management

4. Continuous Improvement

There may be opportunities to improve management processes during the life of the project or information that assists the management of future projects. Continual systematic approaches to quality improvements such as adherence to Total Quality Management (TQM), ISO 9000, Six Sigma or any external industry standards, can be used.

This is part of corporate governance – if there is a variance on a project then it must be corrected, however the root cause of the problem must be understood to ensure that the same problem does not occur on further projects. A continuous systematic approach to Quality Management creates steady growth and improvement to keep a Company focused on its goals and priorities.