1.1 Introduction

Determining what materials and services to purchase is the first and one of the most crucial steps in the procurement process. Responsibility for this determination varies with the requirement. In many cases, the using department is responsible. For example, Plant Engineering is responsible for developing equipment requirements. Plant Operations develops requirements for operating

supplies such as drill bits, lubricating oils, and related items. Administrative Services initiates requirements for office supplies, equipment, and services.

The responsibility for determining which component materials to specify for newly designed products is a complex issue, complicated by the frequently conflicting interests, orientations, and biases of the many departments that have an interest in the end item or service. For example, Engineering may desire design excellence. Marketing may demand nonstandard and unique features. Operations prefers long production runs utilizing existing equipment, requiring few operators, and using high-quality, easy-to-work materials. Purchasing prefers to buy readily available materials from several dependable sources at reasonable prices.

Historically, Purchasing contributions to the organization’s success have been seen as being in two basic areas:

- ensuring the timely availability of required supplies and services and

- Obtaining them at economic prices.

However, these contributions are greatly expanded when purchasing is included at the beginning of the design process. For instance, as material requirements are developed, purchasing should ensure that only essential needs are incorporated in the requirement. The description of the requirement (usually a specification) should not contain features that unduly limit competition among qualified suppliers. Further, purchasing can help the designer to be sensitive to the relative availability and cost of the alternative materials that may satisfy product requirements. Timely availability of required materials and services usually is enhanced by the availability of two or more qualified sources or carefully structured strategic alliances.

1.2 Purchase requisitions/statement of work

The most common method of informing purchasing of material needs is through a purchase requisition. Users may also transmit their needs by phone, by word of mouth or through a computer generated method. Although there are a variety of purchase requisition formats, every requisition should contain the following;

Description of required material or service

Quantity and date required

Estimated unit cost

Operating account to be charged

Date of requisition (this starts the tracking cycle)

Date required

Authorized signature

Although varieties of formats exist, at a minimum a purchase requisition should include a detailed description of the material or service, the quantity, date required ,estimated cost and authorization. This form of communication for a specific need is called a requisition. A requisition is an electronic or paper form that provides some critical information about the need. A typical requisition will provide a description of the product (e.g a valve) the material and color (brass, red valve), the quantity required (20 red brass valves), the intended purpose (20 red brass valves to be used in a maintenance project for equipment XYZ) and the required date for delivery (three weeks).

Sometimes a service is required. For instance, marketing may want to purchase an advertising campaign R & D may need a clinical trial or human resources may need to print a brochure. In this case, the user will complete a statement of work (SOW) that specifies the work that is to be completed, when it is need and what type of service provider is required.

A standard purchase requisition or SOW is used most often for routine, noncomplex items that are increasingly being transmitted through online requisitioning systems linking users with purchasing. An online requisition system is an internal system designed primarily to save time through efficient communication and tracking of material requests. Users should use these systems only if

they require purchasing involvement. It is possible that users have access to other systems that will allow them to purchase an item directly from a supplier such as corporate procurement card. In that ease requisitions forwarded to purchasing are unnecessary.

There are wide differences across organizations in the quality and use of electronic purchase requisition systems. A system that simply requires users to submit to purchasing what they require for electronic transmission is similar to electronic mail. This type of system provides little added value except to speed the request to purchasing. Conversely, one system was so complex that users were afraid to use it.

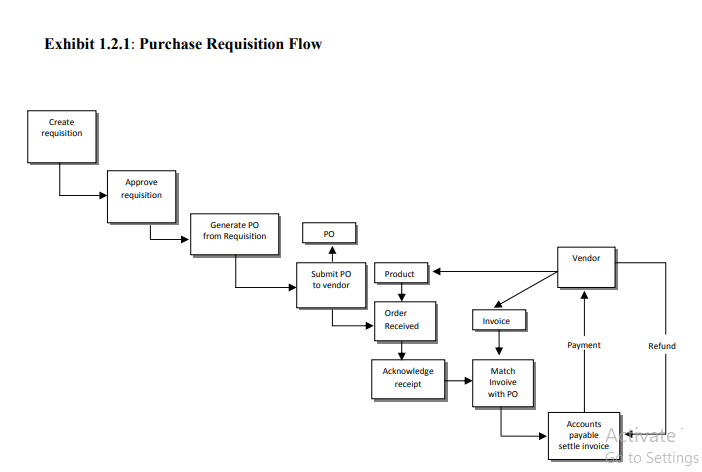

This type of system provides little added value except to speed the request to purchase. They bypassed online requisitioning and relied instead on the phone or intracompany mail. Exhibit 1.2.1 provides further details regarding how a purchase requisition is approved, converted into a purchase order, and ultimately prepared for delivery and payment. Although the user may suggest a supplier, purchasing has final selection authority.

For routine, off the shelf items, the requisition may contain all the information that purchasing requires. However, for technically complex or nonstandard items, Purchasing may require additional information or specifications with the requisition. Examples of such specifications include the grade of material method of manufacture and detailed measurements and tolerance. Purchasing may send an acknowledgment of the receipt of the purchase requisition to the requestor. This acknowledgment often takes the form of a confirming order requisition. The acknowledgement may be a separate form notifying the user that purchasing has received and is

processing the requisition, or it may he a copy of the original requisition. The confirmation verifies the accuracy of the user’s material request.

1.3 Methods of communicating material needs

There are various ways of communicating material needs, namely

1.3.1 Travelling purchase Requisitions/Bar Code

Materials needs are also communicated through a travelling purchase requisition – a form consisting of a printed card or a bar code with information about whom the item is purchased from. This method is used primarily for very small companies that have not automated their purchasing or inventory management process. Information on the card or the database entry associated with

the bar code can include the following;

- Description of item

- List of approved suppliers

- Prices paid to suppliers

- Reorder points

- Record of usage

A travelling requisition can be helpful because it can conserve time when reordering routine materials and supplies. When stock levels reach a specific reorder point an employee notifies purchasing by forwarding the traveling requisition maintained with the inventory or by electronically scanning the bar code into the ordering system. The employee notes the current stock level and desired delivery date. To eliminate the need to research information, the travelling requisition includes information required for the item on the card (or in the data base) that otherwise would require research by a buyer. For example the travelling requisition can include a list of approved suppliers, prices, a history of usage and ordering and lead time information. Historical ordering information is noted directly on the record over a period of time. As inventory systems are used less frequently. With an automated system, clerks simply enter the order requirement and the system generates a purchase requisition or automatically places an order.

1.3.2 Forecast and Customer Order

Customer orders can trigger a need for material requirements, particularly when changes to existing products require new components. Customer order can also signal the need to obtain existing materials. As companies increasingly customize products to meet the needs of individual customers, purchasing must be ready to support new material requirements. Market forecast can

also signal the need for material. An increasing product forecast, for example, may signal the need for additional or new material. If a supplier is already selected to provide that material, then an automated ordering system such as material requirements planning (MRP) systems may forward the material request to suppliers automatically.

1.3.3 Reorder Point System

A reorder point system is a widely used way to identify purchase needs. Such a system uses information regarded order quantity and demand forecast unique to each item or part number maintained in inventory. Each item in a reorder point system, which is usually computerized, has a predetermined order point and order quantity. When inventory is depleted to a given level the system notifies the materials control department (or the buyer, in some organizations) to issue a request to a supplier for inventory replenishment. This signal might be a blinking light on a screen, a message sent to the materials control departments e-mail address, or a computer report. Most recorder point systems are automated using predetermined ordering parameters (such as an economic order quantity, which considers inventory holding and order.

Most reorder point systems are automated using predetermined ordering parameters (such as an economic order quantity, which consider inventory holding and ordering costs). Electronic systems (such as material requirements planning systems) can instantly calculate reorder point parameters. Most systems can also calculate the cost tradeoffs between inventory holding costs, ordering cost

and forecast demand requirements. Reorder point systems are used for production and nonproduction items. An automated reorder point system efficiently identifies purchase requirements. This type of system can routinely provide visibility to current inventory levels and requirement of thousands of parts number. The reorder point system is the most common method for transmitting routine

material order requests today, particularly for companies that maintain spare part distribution centers.

1.3.4 Stock Checks

Stock checks (or cycle counts) involve the physical checking of inventory to verify that system records (also called the record on hand, or ROH) match actual on hand inventory levels also called the physical on-hand (POH) levels. If the physical inventory for an item is below the system amount, an adjustment to that part record can trigger a reorder request for additional inventory. Why might physical inventory be less than what the computerized system indicates should be on hand? Placing material in an incorrect location, damage that is not properly recorded, theft and short shipments from the supplier that receiving did not notice all can contribute to the POH being less than the ROH for example, at one major hardware retailer, missioning inventory on the shelf may be located in another area of the store, or may simply be missing because f a problem with the incorrect item being entered into the system. Smaller firms that rely on standard, easy-to-obtain items often use stock checks to determine material ordering requirements. In this environment, the stock check consists of physically visiting a part location to determine if there is enough inventories to satisfy user requirements. No purchase reorder is necessary if there is enough inventories to satisfy user requirements. No purchase reorder is necessary if there are enough inventories to cover expected requirements.

1.3.5 Cross-functional New-Product Development Teams

When users contact purchasing with a specific need, we say that purchasing is operating in a reactive manner. When purchasing works directly with internal customers to anticipate future requirements, such as during new product development purchasing is being proactive. What does it mean to anticipate a requirement? If purchasing is part of new product development teams, then the opportunity exists to see product designs at early stages of the process. Purchasing can begin to identify potential suppliers for expected requirements rather than reacting to an engineering requirements at a later date anticipating requirements can contribute to faster products development cycle times and better supplier evaluation and selection. As firms continue to be forced to reduce the time required to develop new products cross-functional interactions will increasingly be the means through which organizations identify, and hopefully anticipate, materials requirements in the purchasing process cycle.

However the need is clarified, the point here is that a requisition document is completed by requisitioner. A requisitioner is someone who is authorized by purchasing to complete the needs clarification process. In some cases, the person who expresses the need can also be the requisitioner. This occurs in case where the supplier has already been qualified, and the individual who has the need can go to a supplier’s online catalogue, order the product or service directly and pay for the item using a company purchasing credit card. In such cases, the item is typically low cost, and it is not worth the expense and trouble completing an entire requisition.

1.4 Developing the Right Purchase Description

Within the requisitioning, it is important to include a description of what is to be sourced. Why? If the time is not spent to describe the product or service purchasing will have no idea of what to go out and purchase! How purchasing accomplishes this will defer dramatically from one situation to the next.

There are two main problems common in the area of purchase descriptions:

- Requiring activities frequently fail to consider the cost implications of alternative proaches to describing their requirements.

- Purchasing departments often fail to conduct systematic procurement research and analysis on alternate materials when appropriate.

The word requirement means “need,” not product or service type, which is a solution to a need. All purchasing starts with need determination, and this process eventually is translated into products or services, which then direct us to potential suppliers and the cost of the solution. Under appropriate circumstances, need determination may include carefully screened suppliers. Jumping to a product skips the essential first step of identifying alternatives and can result in automatic supplier selection, locked-in high costs, mistakes causing very expensive change orders, and users doing the buying-all potentially uneconomical actions. For example, if the need is to join two pieces of material together, we can weld, bolt, glue, screw, or use other methods to fasten, that is, the need is

to “fasten together” and the requirement determination process is which method, then which product, then which supplier.

This kind of thinking also forces the investigation of new methods and helps prevent the continued use of obsolete products/procedures.

1.5 Classifying an Inventory Catalog

An inventory catalog should be coded according to several classifications, easily done today with computer data systems. A few classic classifications are:

1. Buying-Using Experience. Is the product/service a new buy, modified rebuy (same product type, slightly different need), or straight rebuy? This will determine the amount of effort needed to determine the requirement. Most of the straight rebuys are via systems contracts, electronic data interchange (EDI), and such; they should be “automated” with requirements changed as the need dictates.

2. Value-Volume Relationships. This is the familiar ABC inventory analysis, which usually starts with a finding that A items account for 80% of the dollars spent but represent just 20% of the physical volume, B items represent 15% of the dollars spent for 30% of the physical volume, and C items represent 5% of the dollars for 50% of the physical volume. This traditional analysis targets candidates for special study. Critical items that can shut the operation down also qualify as A items. Requirements for A items are obviously the top priority, for they are the real cost drivers.

3. Type of Product or Service. Capital goods, especially production machine tools, call for a vastly different requirement determination than most raw materials or maintenance, repair, and operating (MRO) supplies.

Coding your inventory catalog according to the above classifications have the following advantages:

- facilitate rapid computer

- printouts to give direction to purchasing research assignments.

- It helps the purchasing department focus activities to achieve the highest payoff.

- It also helps to explore the questions of simplification and standardization to avoid too many unnecessary requirements and/or slight variations adding little or nothing to value.

- Serving a medium of communication by enabling staff to tell which items are carried in the inventory, whether interchangeable items are carried in the inventory for missing items . etc

- Acting as an inventory control tool through reduction of duplicate records for identified parts.

1.6 The Importance of the Purchase Description

Once the buyer has known the need, he or she can now write the purchase description that forms the heart of any procurement. the process of describing purchase is known as specification. specification can be defined as a statement of needs. It defines what the purchaser wants to buy and, consequently, what the supplier is required to provide. Specifications can be simple or complex depending on the need. The success of the purchasing activity relies on the specification being a true and accurate statement of the buyer’s requirements.

Apart from being a means of identifying the goods or services required, a specification will form part of any future contract that might result from offers received. The specification forms part of an “Invitation to Offer” document. Other elements in the invitation

document include the “Conditions of Offer”, the “Conditions of Arrangement/Supply/Contract” and “Form of Offer” and response schedules.

Good specifications should:

• state the requirement clearly, concisely and logically in functional and performance terms unless specific technical requirements are needed;

• for goods, state what the item will be used for;

• contain enough information for offerors to decide and cost the goods or services they will offer and at what level of quality;

• permit offered goods or services to be evaluated against defined criteria by examination, trial, test or documentation;

• state the criteria for acceptance of goods or services by examination, trial, test or documentation;

• provide equal opportunity for all potential suppliers to offer goods or services which satisfies the needs of the user, including goods or services incorporating alternative solutions;

• form the fundamental basis of the contract between buyer and seller;

• not over-specify requirements; and

• not contain features that directly or indirectly discriminate against any suppliers

Whether a purchase order or contract will be performed to the satisfaction of the buyer frequently is determined at the time the purchase description is selected or written. In no other form of communication is there a greater need for clarity and precision of expression. The extent of this precision has a major bearing on the successful completion of the procurement.

Purchase descriptions serve a number of purposes. Some of these are used to do the following:

- Communicate to the buyer in the purchasing department what to buy

- Communicate to prospective suppliers what is required.

- Serve as the heart of the resulting purchase order.

- Establish the standard against which inspections, tests, and quality checks are made.

The purchase description can greatly influence the amount of competition. The amount of competition has a major impact on the purchase price. The type of purchase description also may affect the “depth” of competition: This depth of competition may have an even more pronounced effect on the purchase price.

1.7 Approaches to Describe What to Purchase (specifications)

1. Brand or Trade Name

The use of a brand name is the simplest way to describe what to purchase. A brand name is used by a manufacturer to distinguish a product and to aid in its promotion. Brand names ensure that the goodwill developed in satisfied customers is credited to the product. Such goodwill requires that the manufacturer provide consistent quality. Using a brand name description implies a reliance on

the integrity and the reputation of the manufacturer. When purchasing by brand name, the purchaser has every right to expect that follow-on purchases of the brand name will possess the same quality as the original. Normally the expression “or equal” should be used immediately following a brand name to facilitate competition. When using an “or equal” after a brand name, it is desirable to set forth those salient physical, functional, or other characteristics of the referenced product that are essential to the purchaser’s needs. The term or equal means that any proposed item should be able to perform the function to the same level of satisfaction as does the specified brand.

Although the use of brand names simplifies the procurement process, it tends to be expensive. Even when competition is introduced through the use of the “or equal” provision, higher prices tend to result than when several of the alternative descriptions of the item are employed. Brandname products generally are sold at higher prices than unbranded products of similar quality. There are several advantages and disadvantages in specifying brand names.

Advantages

- Describing the desired item is simple for the requiring department.

- Purchasing by brand name is relatively simple.

- Brand-name products tend to be more readily available than unbranded items.

- The use of a brand-name purchase description may be the most efficient method of obtaining a desired level of quality or skill when this level of quality cannot be defined easily.

- The branded item may be advertised so widely and successfully as to aid in promotion of the product in which it will be incorporated.

- Inspection of brand-name items is relatively simple.

- Testing of an item may be impractical. The purchaser may avoid such testing by relying on the brand-name manufacturer’s quality standards and test reports.

- The purchaser is assured that the manufacturer will stand behind his or her brand-name product.

Disadvantages

- Brand-name products usually cost more.

- Using brand-name products may mean that the purchaser is not taking advantage of improvements introduced by competitors of the brand-name manufacturer.

- The use of the “or equal” provision may mean that items are purchased from a variety of manufacturers. Since each manufacturer exercises its own quality control, the quality variation probably will be larger than if the item were purchased from one source only or purchased by detailed specification. When commonality of items from purchase to purchase is essential, the use of “or equal” is not desirable.

2. Samples

The need to develop a purchase description sometimes is avoided through the use of samples. Prospective suppliers are invited to match or duplicate the buyer’s sample. Such an approach may be appropriate when special, nonrepetitive items are to be purchased and quality requirements are not a significant factor.

Advantage

- Use of samples is a very simple method of communicating what is required.

- It is almost mandatory when purchasing materials requiring a specific color, feel, finish, or look, such as painted printed surfaces, fabric, style, film, packaging, signs, letterhead stationary, and the like.

Disadvantages

- Detailed tests and inspections may be required to determine that the furnished item meets the sample.

- The inspection on a requirement such as color may be very subjective.

- No definite standards are established either for record-keeping purposes or as the basis of future purchases.

- If the sample is exactly reproduced, all performance warranty responsibilities shift to the buyer as the supplier has performed as per the instructions from the buyer.

3. Standard Specifications

Recurring needs for a consistent level of quality have led industry and government to develop standard specifications for many items. Standard specifications include commercial standards, country specifications, and international specifications. Such standard specifications contain descriptions of the quality of materials and the quality of workmanship to be used in manufacturing the item. Testing procedures are included to ensure that those quality standards are met.

Advantages

- The use of standard specifications greatly facilitates communications. The requirer, purchaser, and supplier all know what is needed.

- The cost of developing a design specification is avoided.

- The use of standard specifications results in wider competition and lower prices.

- The use of standard specifications facilitates the firm’s standardization program, resulting in savings in purchase price, inspection, materials handling, and inventory carrying costs.

- Standardized items tend to be more readily available.

- Designs developed by professional societies are often state of the art and thoroughly tested.

Disadvantages

- Standard specifications may be dated. Accordingly, the buyer may not be taking advantage of the latest technology.

- The specification may call for inputs or processes that are difficult or expensive to achieve.

- Testing costs might be higher than with brand-name products, as there is less performance history.

- As with samples, responsibility for the suitability of the purchased item rests with the purchaser. Normally, the supplier who produces under a specification cited in a purchase order is not responsible for ensuring that the item will satisfy the customer’s need. (With a performance specification, this responsibility is shifted to the supplier.)

- The use of standard specifications results in the purchase of standardized items. The incorporation of such standardized items in the purchaser’s end product may conflict with marketing’s desire to sell a unique product.

4. Design Specifications

Design specifications* spell out in detail the materials to be used, their sizes, shapes, and tolerances, exact physical and chemical characteristics, and how the item is to be fabricated. They provide a completely defined item capable of manufacture by a competent manufacturer. They also describe test procedures to be used to verify that all stated requirements have been met. The specification must meet the requirements of many departments in the firm: Engineering’s concern for technical adequacy, Marketing’s concern with consumer acceptance, Manufacturing’s concern for ease of production, and Purchasing’s concern for availability and economy. As would be expected, design specifications often use commercial standards and other standard specifications.

Since design specifications frequently are the basis of competitive bidding, they must communicate what is needed without need for further clarification. Thus, critical dimensions must be spelled out in detail, and all necessary quality requirements must be fully described. Concomitantly the specification must avoid imposing unnecessary conditions that would disqualify an otherwise acceptable product because it fails to meet a nonessential condition. The design specification must convey a complete and accurate understanding of what is required. The same word or expression is subject to different interpretations by different people. The supplier will

interpret the specification to its own advantage.

A specification essentially is the means of transferring knowledge between minds. Each mind will test the words of a specification against its own experience. If the design specification is ambiguous, the ambiguity will be construed against. Blueprints and engineering drawings are included under the heading of design specifications. Blueprints and drawings should include a

statement of function.

When design specifications control performance under a purchase order or a contract, there is a presumption that the specifications are adequate for the purposes intended and that, if followed, the desired outcome will be obtained. There is an implied warranty that the specifications are adequate. Thus, the supplier who produces under the customer’s specification is not responsible for the suitability or acceptability of the resulting product. However, if the supplier knows (or perhaps from experience should know) that the desired product cannot be obtained, it cannot make a useless thing and expect to be paid for it. If the supplier knows (or should have known) that the specification is defective, it is obligated to notify the customer of the defect. The supplier discharges this obligation by making the defect known to the customer.

As might be expected, design specifications must be reviewed periodically and updated. Unfortunately, the use of design specifications tends to complicate purchase order administration (follow-up and expediting) and may increase costs, delay delivery result in delivery of obsolete items, and sharply increase inventory carrying costs. The use of design specifications may create a costly storage and distribution system for items that are not generally commercially available. There are several advantages and disadvantages in using design specifications.

Advantages

- The purchasing organization avoids having to purchase on a sole-source basis. savings can be enjoyed by avoiding sole-source situations.

- The purchasing organization avoids paying premium prices on branded goods.

- Design specifications facilitate the corporate standardization program, and many savings are enjoyed through such a program.

- They can solve the problem of “no supplier can design it,” if true.

Disadvantages

- Design specifications are expensive to develop. Both time and human resources are required.

- The purchaser is responsible for the adequacy of the specification and the buying firm may use obsolete technology.

- The use of design specifications may deny the purchaser the latest advances in both technical development and manufacturing processes.

- Using a design specification for material that is very similar to an item covered by a commercial standard may result in higher unit prices. Further, the item covered by the design specification will tend to be less readily available.

- The use of design specifications restricts competition to one approach or concept. As we have seen, competition of concepts resulting from use of a performance specification may lead to significant financial and time savings.

- Purchase through the use of design specifications tends to complicate the purchase order administration function. Late delivery of unique items is much more common than it is for standard ones.

- The purchaser usually assumes the inventory responsibility for such unique items.

5. Performance Specifications

Performance specifications generally describe a product by its capacity, function, or operation instead of by its physical, chemical, or quality characteristics. The supplier need only demonstrate acceptable performance to achieve acceptance of the product. A performance specification provides a description of the intended use of an item (whether component, plant, or equipment). A performance specification may include a statement of the qualitative nature of the item required. When necessary, it may set forth those minimum essential characteristics and standards to which such item must conform to satisfy its intended use. Performance specifications describe in words what the item is to do instead of describing the item in terms of its physical and chemical properties.

Although a performance specification is much shorter and easier to develop than a design specification, caution must be exercised in its development. Once again, engineering, marketing, manufacturing, and purchasing requirements must be considered.

The following general principles apply to the development of performance specifications:

- The performance specification must not be so narrow that it stifles creativity.

- While unnecessarily restrictive performance specifications are undesirable, the performance specification must be sufficiently specific to obtain desired objectives. If it is written too broadly, potential suppliers may choose not to respond because of the uncertainty and risk involved, their inability to relate work requirements to their talents and capabilities, or difficulties in estimating costs.

- The performance specification serves as the nucleus of the purchase order or contract. The resulting performance is a direct function of the quality, clarity, and completeness of the specification.

- The element of risk to the supplier inherent in producing under the performance specification should affect the type of pricing on the resulting purchase order (e.g., firm fixed price, fixed-price incentive). As with other approaches to defining and communicating the requirement, the use of performance specifications has inherent advantages and disadvantages.

Advantages

- Performance specifications are relatively easy to prepare.

- Their use tends to avail the purchaser of the latest technology.

- Using performance specifications ensures that the purchaser obtains the specified (desired) level of quality.

- When several already designed, developed, and produced items can meet the performance specification, the depth of competition is enhanced and purchase costs are reduced.

- Performance specifications allow a greater degree of innovation by suppliers. Under performance specifications, the supplier assumes the responsibility of providing a product suitable to the purchaser’s need.

Disadvantages

- Marginal suppliers look for loopholes in specifications. Care and effort must be taken to screen potential suppliers to ensure that only reputable ones are asked to submit proposals. The use of performance specifications is restricted by purchasing’s ability to select capable and ethical suppliers-the kind who do not look for loopholes.

- Competition tends to be reduced when the performance specification requires potential suppliers to perform considerable engineering in preparation for submitting a bid or proposal. Reduced competition may result in higher prices.

1.8 The general process of developing the specifications

Step 1: planning and analysis

The foundation of a good specification is in the planning and analyses which are undertaken before writing begins. Key people who can help such as purchasing staff, technical officers, project officers and managers and end users need to be involved. Planning and analysis will provide a better understanding of the requirement(s) and may reveal alternative solutions. Planning and analysis are particularly important when developing complex requirements. These may take some time to define, perhaps even years in the case of major equipment. The accuracy and detail of the definition is likely to improve as information is gathered and assimilated. Define the requirement(s) and then approach industry to see what is available to meet the department’s/agency’s needs. If industry is approached too early in the development process, there is the risk of deciding the solution to the problem before the requirement(s) is fully defined.

In some cases potential solutions may be discovered and explored which may allow refinement of needs. Think in terms of the performance required or the functions to be performed. In other cases, however, solutions may not be readily available or there could be the danger in stating a solution up front that may restrict offers of alternative solutions. In this situation, a full explanation of the

issue or problem is needed.

Breaking down the requirement(s) in terms of function and performance will better define the need. Defining the requirement(s) in terms of the lowest level functions or sub components should also help to discover conflicts and inconsistencies within the requirement(s). Alternative solutions, too, may be revealed in the process. Value analysis could be used to highlight and explore possible solutions. It is a complex cost analysis technique that requires expertise for its successful use. In simple terms, value analysis

looks for the optimum way of using materials, designs, equipment etc. to meet a (functional) requirement while providing savings over the life of the equipment or at the initial purchase stage. The technique is particularly useful in identifying potential, innovative solutions.

Step 2: Consultations and information gathering

Developing specifications requires consultation and can be perceived as an evolutionary process involving close and continuous liaison between the end-user, technical officers, project officers/managers, purchasing officers and the specification writer. Valuable information and advice relating to the requirement can be obtained by discussing it with purchasing officers, technical officers and other users of similar goods or services within the department/agency. Purchasing officers should be involved from the start of the process (that is, the information gathering and design stages).

Other sources of information include:

• other departments or agencies (including Federal and Local Governments);

• industry – either industry associations or particular companies (ensure that industry does not assume pre-offer negotiations);

• educational institutions, for example, universities and TAFE Institutes;

•Country standards;

• Industrial Supplies Office Ltd (ISO Queensland) which can assist in identifying and evaluating appropriate local industry capabilities; and

• other users of the goods or services.

These organizations may help to refine the requirement and also suggest potential solutions.

Step 3: writing specifications

• Use simple, clear language without jargon (to minimize misinterpretation).

• Define terms, symbols and acronyms (include a “Glossary of Terms”).

• Be concise.

• Do not explain the same requirement in more than one section.

• Define each aspect of the requirement in one or two paragraphs where possible.

• Adopt a user-friendly format.

• Number the sections and paragraphs.

• Seek feedback from someone unfamiliar with the requirement.

• Discuss the draft and refine it.

There are no fixed rules on formats and structures because each specification reflects a different requirement or need. A specification should list the functional, performance and technical characteristics separately. Refine the structure before writing by discussing with colleagues and purchasing officers. Include tables, sketches, diagrams, or statistical matter if these help to make the specification clearer. Be careful that these types of information do not limit the options for offerors to provide alternative solutions.

Step 4: Vetting specifications and obtaining approval

After writing the specification, ask a colleague who is unfamiliar with the requirement to critique it from a potential supplier’s view.

Try to identify improvements by considering:

• readability,

• simplicity of meaning,

• clarity, and

• logic.

Seek approval from the appropriate financial or purchasing delegates in the department/agency vetting the specification but before issuing it.

Step 5: issuing the specifications

The specification should be included as part of the “Invitation to Offer” document. The “Invitation to Offer” should target suppliers that are capable of meeting the specification by direct approach (after market analysis) or through advertising in newspapers, websites and industry magazines, etc.

Step 6: managing amendments to the specifications

Should a need arise to amend the specification during the “Invitation to Offer” process, the amendment should be authorized by the project manager. The amended specification should be noted in the project files and all offerors or potential offerors must be given a reasonable opportunity to offer to the new specification.

Step 7: Revising and storing the specifications

The specification should be reviewed at the end of the purchasing activity to ensure that it effectively defined the goods or services that were actually bought. If areas for improvement are identified, revise the specification with the benefit of hindsight. When the review of the specification has been completed and if it relates to goods or services that are likely to be purchased frequently, keep it on file. Before each purchase, review the specification to ensure that it reflects your department’s/agency’s needs at that time. Alternatively,

institute a program to review specifications on a regular basis.

1.9 Selecting the Right Approach to Describing Requirements

Although the decision on what type of purchase description to use may appear to be simple, many factors complicate the issue. For small, noncritical procurements, brand names or samples frequently best describe requirements. The use of a brand name as a purchase description is appropriate to:

- Obtain the desired level of quality or skill when these are not described easily,

- Gain the benefits of wide advertising of the brand-name item that would aid in promotion of the purchaser’s end product,

- Accommodate users who have a bias or prejudice (whether founded or unfounded) in favor of the brand. Such prejudices can be virtually impossible to overcome.

When brand names or samples are inappropriate for describing requirements, some type of is employed. When selecting or developing the specification, consideration must be given to the importance of competition and the desirability of avoiding unnecessarily restrictive criteria. Once a need has been identified and functionally described, and when the size of the contemplated purchase warrants, procurement research and analysis should be conducted to investigate the availability of commercial products able to meet the company’s need. Normally, these commercial products are described by one of the standard specifications. This research and analysis also should provide information to aid in selecting a procurement strategy appropriate to the situation.

Procurement research and analysis involves obtaining the following information as appropriate:

- The availability of products suitable to meet the need (with or without modification)

- The terms, conditions, and prices under which such products are sold

- Any applicable trade provisions or restrictions or controlling laws

- The performance characteristics and quality of available products, including quality control and test procedures followed by the manufacturers

- Information on the satisfaction of other users having similar needs

- Any costs or problems associated with integrating the item with those currently used

- Industry production practices, such as continuous, periodic, or batch production

- The distribution and support capabilities of potential suppliers

If a suitable commercial product is unavailable at a reasonable price, a determination should be made on whether to use a design or a performance specification.

Summary

Once the need or required function is determined, the purchase description forms the heart of the procurement. The organization’s satisfaction with the purchased item frequently is determined at the time the purchase description is selected or developed. Purchase descriptions communicate to the buyer what to purchase, communicate to prospective suppliers what is required, serve as the principal element of the resulting purchase order or contract, and establish standards for inspection. Five types of purchase descriptions have been described: brand or trade names, samples, standard specifications, design specifications, and performance specifications. Each has inherent advantages and disadvantages; no one approach is right or best in all circumstances.