1.1 Introduction

Purchasing describes the process of buying: learning of need, locating and selecting suppliers negotiating prices and other pertinent terms, and follow up to ensure delivery. It entails the following activities:

- Purchase needs identification through liaison with user departments.

- Identification of potential suppliers and negotiation.

- Selection of suppliers.

- Market research for important materials.

- Analysis of proposals.

- Issuance of purchase orders.

- Administration of contracts and resolutions of related problems

- Maintenance of purchasing records.

- Procurement is a broader term and includes purchasing stores, traffic, receiving, incoming inspection and salvage. Procurement and purchasing are used interchangeably, this is however somewhat imprecise. Procurements process or concept encompasses a

wider range of supply activities than those included in the purchasing functions .it includes the traditional role, with more buyer participation is related material activities.

These activities include;

- Development of material and service requirements and other specifications.

- Materials research and value analysis activities.

- Extensive market research.

- Conduct of all purchasing functions.

- Suppliers quality management

- Management of investments recovery activities (salvage of surplus and scrap)

Essentially therefore procurement tends to be broader and more proactive, focusing on strategic matters, rather than mere implementation of purchasing concept. Supply management is a system management concept employed by some organizations designed to optimize the factors of materials costs, quality and services. It is a process responsible for the development and management of a firm’s material management of a firm total supply system. It includes and expands the activities of the purchasing function and the procurement process. The other activities in supply management are:

- Early Purchasing Involvement (EPI) and Early Supplier Involvement (ESI) in product design and subsequent specification development for crucial items.

- Heavy use of cross–functional teams in supplier qualification and selection.

- It depicts effect to develop better, more responsive supplies than the term purchasing.

- Purchasing partnering and strategic alliances with supplies.

- Strengths Weaknesses Opportunities and Threats (SWOT) analysis.

- Continuous monitoring and improvement in the supply chain.

- Participation in strategic planning process.

Materials Management is the integration of related materials functions to provide cost effective delivery of material and services to an organization. It is an organizational concept from a managerial perspective designed to enhance coordination and control of

the various materials activities. Since action or decision taken at any point in the materials chain, usually impacts on a number of other activities or decision point in the chain, it is imperative to enhance reporting, communication and control procedures designed to enhance a coordinated decision making among the involved groups or departments. Materials management includes the following activities:

- Purchasing and supply management activities.

- Inventory management

- Receiving activities

- Stores and warehousing

- In-plant material movement

- Production planning, scheduling and control

- Traffic and transportation

- Scrap and surplus disposal.

Supply chain management is a system approach to managing the entire flow of information, materials and services from raw materials, supplier through factories, warehouses to end customers

1.2 The Evolution of Purchasing

Purchasing can be traced as far back as 2800 BC in cuneiform clay tablets purchasing orders. Curiously only during the past two countries has purchasing been addressed in trade books and text books. In 1832 Charles Babbage addressed purchasing in his book “On the Economy, Machinery and Manufacturing” The first book devoted specifically to purchasing, “The Handling of Railway Supplies: The Purchase and Disposition” published in 1887 was authored by Marshall M. Kirkman. The first college textbook on purchasing was authorized by Howard T. Lewis of Harvard University in 1933. Although interest of purchasing and supply function has been a phenomenon in the 20th, it was recognized as independent and importing function well before 1900. Growth of interest and attention to purchasing was rather uneven in the early 1900’s but by 1915, several books on purchase had appeared and several articles had been published in trade press primarily in the engineering journals.

Yet prior to World War I (1914-1918) most firms regarded the purchase function primarily as a clerical activity. However during the world war, the ability to obtain raw materials supplies ad services needed to keep the factories and mines operating were the key determinates of organizational success. Attention was given to the organization policies and procedures for purchase functions, and so it emerged as a recognized management activity. Historically since management interest has focused on research and development,

marketing, finance and operations, purchasing has frequently been subordinated to these functions. Mangers are however becoming aware impact on the bottom line that does any other functions. It is with such insights the purchasing has evolved and evolves through

the following four stages.

Passive stage– Purchasing function has no strategic direction and primarily reacts to the requests of other functions,

This stage is characterized by:

- High proportion and individual communications due to purchasing low visibility

- Supplier selections based on price and availability.

Independent stage– Purchasing functions adopts the latest purchasing techniques and processes, but its strategic direction is independent of the firms competitive strategic.

In this stage;

- Performance is based primary on cost reduction and efficiency measures.

- Coordination links are established between purchasing and technical discipline.

- Top management recognizes the importance of professional development.

- Top management recognizes the opportunities in purchasing for contribution to profitability

Supportive– Purchasing function support the firm’s competitive strategy by adoption purchasing techniques and products which strengthens the firm’s competitive position

In this stage;

- Purchase is included in sales proposal teams.

- Suppliers are considered a resource with emphases on experience motivation and attitude.

- Market product and suppliers are continuously monitored and analyzed.

Integrative stage- Purchasing strategy is fully integrated into the firm’s competitive strategy and constitutes part of an integrated effort among peers to formulate and implement a strategic plan. In this stage;

- Cross-functional training of purchasing professionals executive is made available

- Permanent lines of communication are established among other functional areas.

- Professional development focuses on strategic elements of the competitive strategy

- Purchasing performance is measures in terms of contributions to the firm’s success

1.3 The Role of the Purchasing Department

The purchasing department is expected by the management to fulfill the following five rights.

- Right Quality

- Right Suppliers

- Right Quantity

- Right Time

- Right Price

These rights are also referred to as the principles of purchasing. In order to undertake these rights the purchasing department delineates the following as in roles;

- To support company operations with an uninterrupted flow of materials and services.

- To buy competitively- Keep abreast of the forces of demand and supply that regulate prices and material availability on the market; understanding suppliers cost structure and ability to help reduce it further; price negotiation to help reach a fair price.

- To buy wisely- Continual search for better vales that yield the best combination of quality service and price; reconciling users needs with suppliers capabilities by use of cross functional teams;

- To keep inventory investment and inventory losses at a practical minimum.

- To develop effective and reliable sources of supply- “buy suppliers” not “products” e.g. co-operatives.

- To develop good relationship with suppliers community and good Continuing relationship with active suppliers- good relationship with potential suppliers is invaluable.

- To achieve maximum integration with other departments of the firm Understanding major needs of user departments and provide such support as; standardization of programmes, future price forecasting, make or buy analysis and providing a repository of information and data from suppliers.

- To handle the purchasing and supply management function proactively and in a professional cost effective manner- Continual analysis of activities to eliminate those that only marginally contribute to the effectiveness of the organization and establishing policies and procedures that achieve departments objectives in the most cost effective manner

1.4 The Contribution of Purchasing Department to the Overall Firm’s Performance

As a function, purchasing is common to all types of business operations. The purchasing department however is an organizational unit of a firm whose duties may include responsibility for part or all of the purchasing function and additional activities as well. As a matter of fact, the purchasing function is usually performed most effectively and efficiently by a centralized unit made of buying specialist who a time may work in conjunction with a more comprehensive cross-functional team of specialists.

Prior to the 1950, the purchasing department was a clerically oriented order placing unit. In the ensuing years however, managerial emphasis has focused on specialization of individual buying activities, professionalism and contribution to the firm’s profit. This emphasis by the management on the purchasing department has been borne out to of the realization of the profit potential of purchasing as a function. Every shilling saved in purchasing is equivalent to a new shilling in profit.

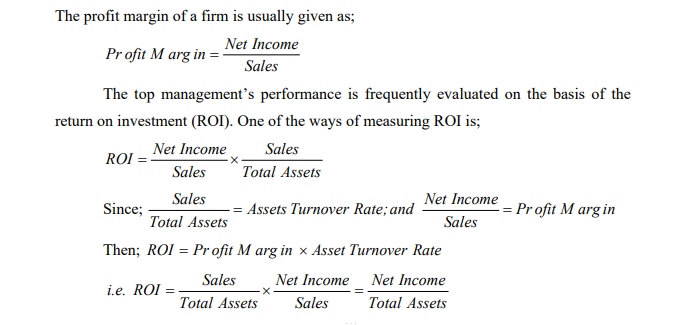

Since firm’s profit margins reflect ability to control cost relative to revenue. The assets turnover rate reflects management’s ability to effectively utilize the firm’s productive assets. Therefore, a firm’s management can improve ROI (managerial performance) by:

- Reducing costs relative to sales.

- Producing more sales from available assets (or increasing sales relatively faster than investment)

- By some combination of the two

Purchasing as such contribute to ROI by both increasing profit margins and by increasing the assets turnover rate.

1.5 The Relationship between Purchasing Department and other Departments

1. Purchasing and Design/Engineering

- Preparation of specifications for purchased material and components.

- Quality assurance or defect prevention

- Value analysis1 and Value engineering2

- Information to design departments regarding availability of materials, suppliers and costs.

- Agreement of alternatives when specified materials are not available.

- Issues arising from the increasing importance of buying rather that making, i.e. reduction of vertical integration.

- Importance of buying completer systems rather than individual components.

- evaluation of cheaper alternate materials;

- Building co-makership/designership relationship.

- Creation of a library of books, catalogues, journals and specifications for joint use by the design and purchasing departments.

2. Purchasing and Production or “User” Departments

- Preparation of material schedules to meet Just–In-Time (JIT) requirements.

- Ensuring that delivery schedules are maintained.

- Control of inventory to meet production requirements.

- Disposal of scrap and obsolete items

- Quality control or defect detection and correction

- Approval of “first off “samples.

- Make or buy decisions

- Sub-contracting decisions

- Suppliers development

- General involvement in such techniques and systems as production technology, computer integrated technology and MRP3 and MRPII4

3. Purchasing and Marketing

- Provision of sales forecasts on which purchasing can base its forwarded planning of materials and components.

- Ensuring that, by efficient buying, purchasing contributes to the maintenance of competitive prices.

- Obtaining materials on time to ensure that marketing and production meets the promised delivery dates.

- Exchange of information regarding customers and suppliers.

- Marketing implications of partnerships sourcing.

- Liaison with respect to reciprocal trading.

4. Purchasing and Finance

- Provision of accurate forecasts of purchase schedules since they have an impact on working capital and cash flow positions of the firm.

- Evaluation of potential income from unexpected buying opportunities against the potential income from other alternative uses of the firm’s capital.

- Co-ordination to arrive are at the right time to buy for the firm (purchasing department’s right time may not be the finance department’s right time)

- A co-operative relationship between purchasing and finance clearly impacts on the development of good supplier relationship e.g. through prompt payments.

Factors Considered When Establishing Purchasing Liaison5

- Expert knowledge required by the department concerned.

- Departmental objectives of all the department

- Responsibility held to every department and how they contribute to the effectiveness within the purchasing function.

- Materials requirements of various departments.

- The channel of communication –free flow of information

Limitations to development of purchasing liaison

- Department conflict due to differences in objects.

- Time is wasted due to slow decision making.

- Any failure in one department could lead to failure in other department.

Focuses in Purchasing and Supply

Historically purchasing focused on internal processes and tactics. In recent years however there has been progression from these focuses to;

1. Value Adding Benefits

Today many world–class organizations expect their purchasing and supply management function to focus on the following value-adding outputs of proactive purchasing.

- Quality- purchased materials and services should be virtually defect-free.

- Cost- strategic cost management through reduction total cost of acquiring, moving, holding, converting and supporting products containing purchased materials and services through out the supply chain.

- Time- the time required to bring a new product to the market can be reduced by 20-40% through the establishment of a world-class strategic supply management system.

- Technology- ensuring the supply base of the firm provides appropriate technology in a timely manner and ensuring that the technology which affects the firm’s core competences is carefully controlled when dealing with outside supplier.

- Continuity of supply- monitoring supply trends, developing appropriate supplier alliances and taking such other actions as required in reducing the risk of supply disruptions.

2. Strategic focus

- Integration- the firm’s strategy must be integrated with the firms marketing, conversion and finance strategies and that of the corporation.

- Business environment- purchasing must address the identifications of threat and opportunities in the supply environment.

- Technology- technology is often used as a strategic tool. Its control is therefore critical in order to insulate it from access from competitors.

- Component and commodity strategies- development of formalized market driven supply plans for critical purchased materials and services.

- Management Information System- ensuring a cost effective, timely and comprehensive information system to provide data necessary to make optimal supply decisions

- Supply base strategy- the supply base that the firm belongs to must be carefully developed and managed to ensure that the firm belongs to a successful value chain in an increasingly competitive market place.

- Centralization of development and management- while low-value adding activities are decentralized the development and management of the firms supply strategy is centralized.

- Use of senior procurement professional- the key supply relationships or alliance is assigned to senior procurement professional.

- Use of professional personnel- the purchasing department is manned by fewer but far more professional personnel.

1.6 Purchasing and Supply Organization Structure

In any given time there are several factors that determine whether purchasing and supply is a top level function reporting to the C.E.O or a Sub function reporting a top level executive such as the head of manufacturing. These factors are;

- Availability of materials- when materials are brought in volatile markets suggest to price instability and periodic shortages then it is wise t have purchasing as a top level function.

- Absolute shilling volume of purchase- where the magnitude of expenditure is high top level purchasing can produce significant profit through nit savings which add in thousand when large purchase are made.

- Percent of product cost represented by materials- if the material costs are 40% or more of its products cost small reductions in material costs increase profit significantly, as such top-level purchasing pays off.

- Types of materials purchased- Most large firms use a wide range of materials, many of whose prices and service arrangement can be influenced by creative purchasing performance. However in firms whose materials are standard top level purchasing can produce little profit.

Types of Organization Structures

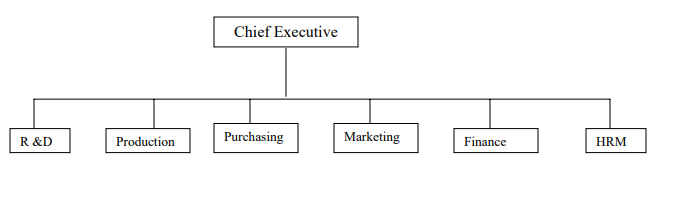

Organization theory identifies three types that represent distinct forms of organizational structures, namely: functional, divisional, and matrix.

1. Functional Organizational Structures

These are based on specializations required to perform the primary tasks of the organization. The specializations include; Research and Development (R and D), Production, Purchasing, Marketing, Finance, Human resource management. An illustration of a functional organizational structure is shown below:

Advantages of a Functional Organizational Structure

Advantages of a Functional Organizational Structure

- The CEO is in touch with all primary functions.

- It gives status to major functional areas.

- Communication and decision making within the function is made easy.

- It simplifies training of functional specialists

- It preserves strategic control at top management level.

Disadvantages of a Functional Organizational Structure

- Co-ordination with other functional areas may be unsatisfactory.

- Emphasis can be on narrow functional rather than wider organizational objectives.

- Tasks are entities in themselves, unrelated to a wider process.

- Many activities do not “add value.”

- Wasteful interdepartmental conflict and rivalry may be encouraged.

- Development of broadly trained managers is limited

- Satisfaction of external and internal customers and suppliers may be low.

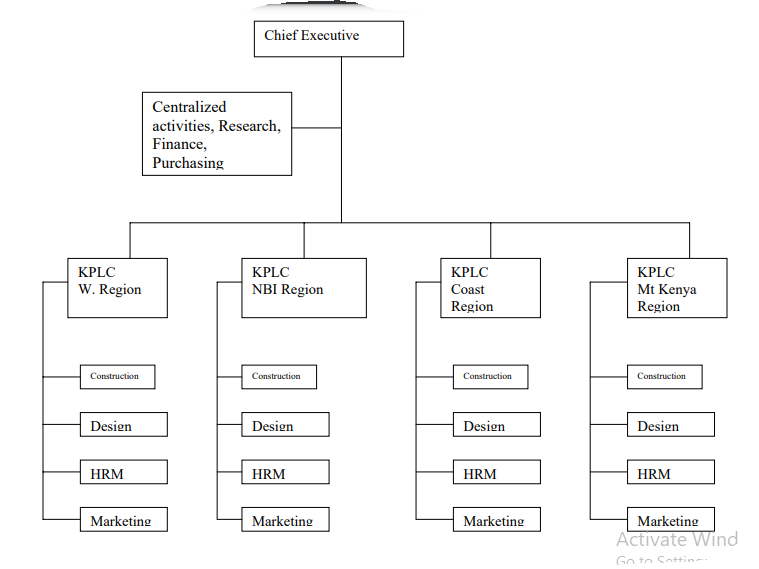

2. Divisional Organizational Structures

These are based on the outputs of the organization i.e. products or services. Other bases for divisionalization include geographical areas or processes. It is the organizational pattern for large, highly diversified organizations, often operating in several regions or countries. At some level, a divisionalized structure will be split into functionally based departments each responsible for a particular function or process. As shown in the illustration below;

Advantages of a Divisional Organizational Structure

- It concentrates on a product, services, geographical area, etc

- It allows units to adapt to local circumstances.

- It adapts to local legal, political and cultural factors.

- It allows general managers to attend to strategies.

- It provides a training ground for general management development.

Disadvantages of a Divisional Organizational Structure

- There is a possible confusion over whether authority and responsibility is centrally or divisionally located.

- There is a possible conflict between divisions.

- There is duplication of functional activities.

- It requires a number of general managers.

- It is expensive (high cost).

- Co-ordination may be complex where there are two many divisions.

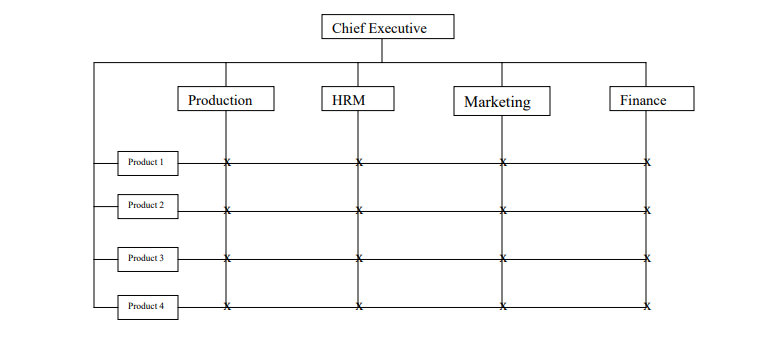

3. Matrix Organizational Structures

These are based on two forms of departmentalization: Functional and divisional members of matrix organizations are therefore simultaneously members of two sources of authority. A functional structure is shown below

Advantages of a Matrix Organizational Structure

- It establishes one person as the focal point for all matters of the organization.

- It makes it possible to respond to the needs of several projects simultaneously.

- It makes maximum use of a limited pool of function specialists.

- It ensures that functional expertise is equally available to all projects

- It provides excellent training for running a diversified organization.

Disadvantages of a Matrix Organizational Structure

- Unity of command is lost (members report to more than one head).

- Authority and responsibilities of managers overlap causing conflicts and gaps in efforts across units and respect of priorities.

- Places a premium on teamwork

- Slows down decision making

- It is difficult to explain to team members

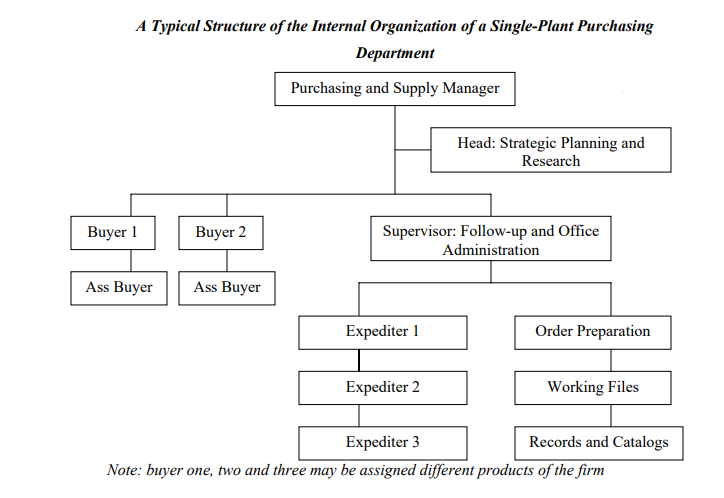

Purchasing and Supply Department Internal Organization in a Single Plant Firm

Purchasing and supply work naturally divides into five district classifications. This permits a high degree of specialization without creating motivational problems for the purchasing personnel. These classifications are;

- Management- emphasizes in development of policies procedures control and the mechanic of co-ordination of the purchasing depth

- Buying- includes working with users to come up with specifications investigating suppliers studying costs negotiations analysis bids and selecting suppliers

- Follow-up and expediting- includes supplier lesson work such as reviewing the stats of orders writing and phoning suppliers and occasionally visiting supplier plants.

- Strategic planning and research work- activities in this area include supply market studies, development of materials buying strategic development of supply base and partnering players, product research and vale analysis work and operating and information system analysis.

- Clerical activities- writing purchase order, main training fuels, catalogue and library materials, records for commodities supplies, prices and so on.

Purchasing and Supply Department Internal Organization in a Multi-Plant Firm

A Multi-plant firm faces an additional organizational questions not faced by single-plant firms. This is the determination of the extent to which purchasing and supply should be centralized at the corporate level or decentralize the function to individual plants giving them full authority to conduct all of their purchasing activities.

Advantages of Multi-plant Centralization

- Greater buyer specialization- permit greater technical specialization leading to development to more knowledgeable and more highly skilled buying personnel

- Economics of scale- by consolidating requirement large purchases are made leading to quantity discounts, rebates and favorable prices.

- Easier purchasing, coordination and control- this permits control and administration of important policies and consistency of purchasing ethics, budgets compliance, supplier relations and consistency of purchasing practices.

- Effective planning and research work- centralization of firm wide purchasing requirements provide the staff with know-how to improve purchasing and supply research work. This allows greater strategic materials planning with more depth and greeter efficiency.

- Lower administration cost- since less staffing is required in a centralized structure is less costly than the decentralized structure.

- Holding and ordering costs will be lower

Advantages of Multi-plant Decentralization

- Easier co-ordination with operating departments- decentralization allows the buyer to be close to the user thus, coordination becomes easier. It becomes easier to form buyer-user teams.

- Speed of operation- transmittal of information from plant to headquarters makes the purchasing procedure long than when the purchasing department is located a the plant.

- Effective use of local sources- with the plants geographically dispersed it is difficult for a centralized purchasing department to locate and develop potentially good supplier near each plant.

- Plant autonomy- fundamental principal of management holds that the delegation of responsibility must be accompanied by delegation of adequate authority to carry out that responsibility. This is crucial especially where plant contribution to a company’s bottom-line is the responsibility of the plant manager.

- Allows integrated problem solving instead of functional specialization.

Note: advantages of each are the disadvantages of the other

Factors affecting Feasibility and Desirability of Centralization

- Similarity of materials usage

- Plant department size

- Geographical dispersion of plants

- Volume to be materials used

- Availability of storage space

- Urgency of material requirements