Measuring store metrics is critical for providing managers with a clear vision of potential issues and opportunities for improvements. Metrics are tied directly to the business strategy and operation‘s success drives the financial results of the organization. If stores are going to contribute to be a source for adding value to the supply chain then they need to measure their performance with perfect metrics. Key objectives in designing stores operations include increasing productivity, reducing cycle time, and increasing accuracy.

There are number of reasons compelling store logistics professionals to investigate productivity solutions. Dynamic fuel costs have professionals up and downstream in the supply chain scrambling to find cost cutting measures and higher operating efficiencies. Large enterprises continue to seek to reduce the number of stocking locations and drive more productivity from the remaining distribution

centers. Literature has shown that cost and space pressures outweigh the pressures to improve operations because of rising customer demands for faster and more tailored fulfillment. However, the best performing companies are focused on winning in both these dimensions: by creating faster throughput and more workflow agility in their store, they are able to satisfy customer demands while lowering logistics costs.

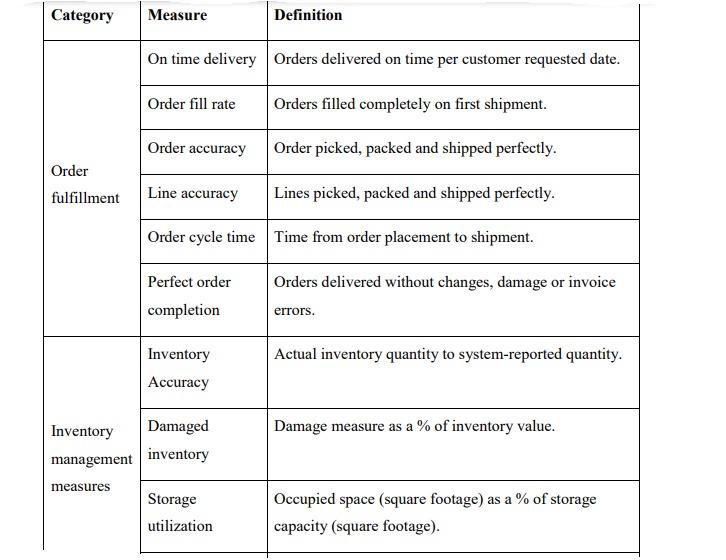

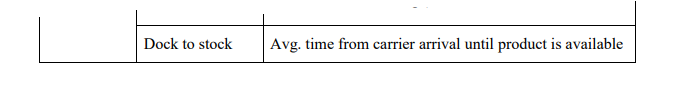

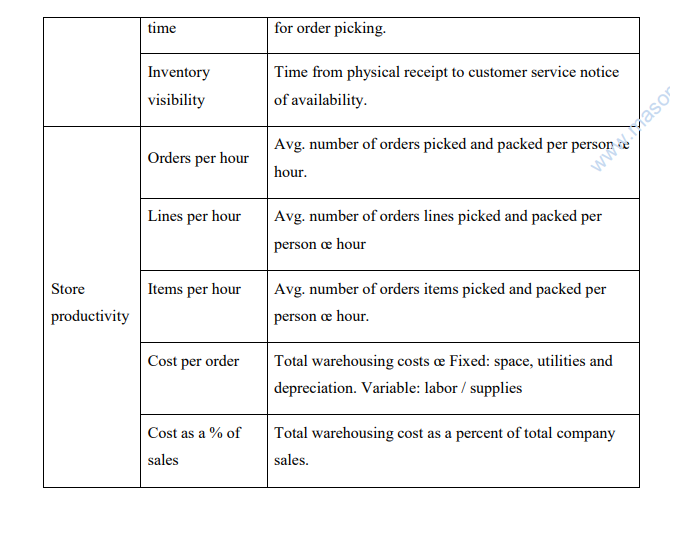

Many times these objectives may conflict with one another, because, a method that focuses on productivity may not provide a short enough cycle time or a method that focuses on accuracy may sacrifice productivity. Researchers and managers typically attempt to find a set of measures which collectively capture most, if not all, of the performance dimensions thought to be important, over both short-and long-term horizons. The metrics for measuring performance in a warehouse fall into three main categories which includes, order fulfillment, inventory management and labor productivity. The various metrics for measuring the performance is as shown in the table