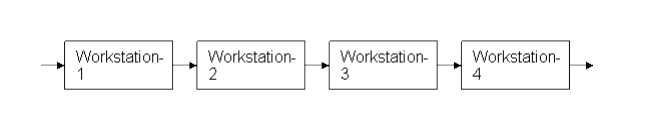

In this type of layout the machines and equipment‘s are arranged in one line depending upon the sequence of operations required for the product. It is also called as line layout. The material moves to another machine sequentially without any backtracking or deviation i.e the output of one machine becomes input of the next machine. It requires a very little material handling.

It is used for mass production of standardized products.

Advantages of Product layout:

• Low cost of material handling, due to straight and short route and absence of backtracking

• Smooth and continuous operations

• Continuous flow of work

• Lesser inventory and work in progress

• Optimum use of floor space

• Simple and effective inspection of work and simplified production control

• Lower manufacturing cost per unit

Disadvantages of Product layout:

• Higher initial capital investment in special purpose machine (SPM)

• High overhead charges

• Breakdown of one machine will disturb the production process.

• Lesser flexibility of physical resources.