CHAPTER FOUR: OPERATION PLANNING

4.1 INTRODUCTION AND MEANING

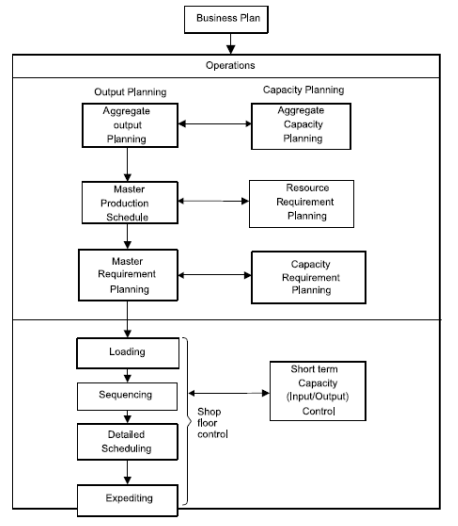

Operations planning and scheduling systems concern with the volume and timing of outputs, the utilization of operations capacity at desired levels for competitive effectiveness. These systems must fit together activities at various levels, form top to bottom, in support of one another, as shown in Fig. 5.3. Note that the time orientation ranges from long to short as we progress from top to bottom in the hierarchy. Also, the level of detail in the planning process ranges from broad at the top to detail at the bottom.

4.2 COMPONENTS OF OPERATIONS PLANNING AND SCHEDULING SYSTEM

1. The Business Plan

The business plan is a statement of the organization’s overall level of business activity for the coming six to eighteen months, usually expressed in terms of outputs (in volume of sales) for its various product groups, a set of individual products that share or consume common blocks of capacity in the manufacturing process. It also specifies the overall inventory and backlog levels that will be maintained during the planning period. The business plan is an agreement between all functional areas—finance, production, marketing, engineering, R & D—about the level of activity and the products they are committed to support. The business plan is not concerned with all the details and specific timing of the actions for executing the plan. Instead, it determines a feasible general posture for competing to achieve its major goals. The resulting plan guides the lower-level, more details decisions.

OBJECTIVES OF THE STUDY:

a) Student should know the components of operation planning

b) The student should know aggregate planning strategies and guideline

c) Master Production Schedule(MPS) and Material Requirement Planning(MRP)

2. Aggregate Production (Output) Planning

The process of determining output levels of product groups over the coming six to eighteen months on a weekly or monthly basis. It identifies the overall level of outputs in support of the business plan. The plan recognizes the division’s existing fixed capacity and the company’s overall policies for maintaining inventories and backlogs, employment stability and subcontracting.

3. Aggregate Capacity Planning

It is the process of testing the feasibility of aggregate output plans and evaluating overall capacity utilization. A statement of desired output is useful only if it is feasible. Thus, it addresses the supply side of the firm’s ability to meet the demand. As for aggregate output plans, each plant, facility, or division requires its own aggregate capacity plan.

Capacity and output must be in balance, as indicated by the arrow between them in Fig. 1.5. A capacity plan translates an output plan into input terms, approximating how much of the division’s capacity will be consumed. Although these basic capacities are fixed, management can manipulate the short-term capacities by the ways they deploy their work force, by subcontracting, or by using multiple work shifts to

adjust the timing of overall outputs. As a result, the aggregate planning process balances output levels, capacity constraints, and temporary capacity adjustments to meet demand and utilize capacity at desired levels during the coming months. The resulting plan sets limits on the master production schedule.

4. Master Production Scheduling (Mps)

MPS is a schedule showing week by week how many of each product must be produced according to customer orders and demand forecasts. Its purpose is to meet the demand for individual products in the product group. This more detailed level of planning disaggregates the product groups into individual products and indicates when they will be produced. The MPS is an important link between marketing and production. It shows when incoming sales orders can be scheduled into production, and when each shipment can be scheduled for delivery. It also takes into account current backlogs so that production and delivery schedules are realistic.

5. Resource Requirement Planning

Resource requirement planning (rough-cut capacity planning) is the process of testing the feasibility of master production schedule in terms of capacity. This step ensures that a proposed MPS does not inadvertently overload any key department, work centre, or machine, making the MPS unworkable.

6. Material Requirement Planning

Material requirement planning (MRP) is a system of planning and scheduling the time phased material requirements for releasing materials and receiving materials that enable the master production schedule to be implemented. Thus, the master production schedule is the driving force for material requirements planning. MRP provides information such as due dates for components that are subsequently used for shop floor control. Once this information is available, it enables managers to estimate the detailed requirements for each work centres.

7. Capacity Requirement Planning

Capacity requirement planning (CRP) is an iterative process of modifying the MPS or planned resources to make capacity consistent with the production schedule. CRP is a companion process used with MRP to identify in detail the capacity required to execute the material requirement planning. At this level, more accurate comparisons of available and needed capacity for scheduled workloads are possible.

8. Shop Floor Control

Shop floor control involves the activities that execute and control shop operations namely loading, sequencing, detailed scheduling and expediting jobs in production. It coordinates the weekly and daily activities that get jobs done. Individual jobs are assigned to machines and work centres (loading), the sequence of processing the jobs for priority control is determined, start times and job assignments for each stage of processing are decided (detailed scheduling ) and materials and work flows from station to station are monitored and adjusted (expediting).

9. Loading

Each job (customer order) may have its unique product specification and, hence, it is unique through various work centres in the facility. As new job orders are released, they are assigned or allocated among the work centres, thus establishing how much of a load each work centre must carry during the coming planning period. This assignment is known as loading (sometimes called shop loading as machine loading).

10. Sequencing

This stage establishes the priorities for jobs in the queues (waiting lines) at the work centres. Priority sequencing specifies the order in which the waiting jobs are processed; it requires the adoption of a priority sequencing rule.

11. Detailed Scheduling

Detailed scheduling determines start times, finish times and work assignments for all jobs at each work centre. Calendar times are specified when job orders, employees, and materials (inputs), as well as job completion (outputs), should occur at each work centre. By estimating how long each job will take to complete and when it is due, schedulers can establish start and finish dates and develop the detailed schedule.

12. Expediting

Expediting is a process of tracking a job’s progress and taking special actions to move it through the facility. In tracking a job’s progress, special action may be needed to keep the job moving through the facility on time. Manufacturing or service operations disruptions-equipments breakdowns, unavailable materials, last-minute priority changes, require managers to deviate

from plans and schedules and expedite an important job on a special handling basis.

13. Input/Output Control

Input/output control related to the activities to monitor actual versus planned utilization of a work centre’s capacity. Output plans and schedules call for certain levels of capacity at a work centre, but actual utilization may differ from what was planned. Actual versus planned utilization of the work centre’s capacity can be monitored by using input-output reports and, when discrepancies exist, adjustments can be made. The important components of operations planning and scheduling system has been explained in detail in the following paragraphs.

4.3 AGGREGATE PLANNING

Aggregate planning is an intermediate term planning decision. It is the process of planning the quantity and timing of output over the intermediate time horizon (3 months to one year). Within this range, the physical facilities are assumed to –10 be fixed for the planning period. Therefore, fluctuations in demand must be met by varying labour and inventory schedule. Aggregate planning seeks the best combination to minimise costs. Aggregate Planning Strategies The variables of the production system are labour, materials and capital. More labour effort is required to generate higher volume of output. Hence, the employment and use of overtime (OT) are the two relevant variables. Materials help to regulate output. The alternatives available to the company are inventories, back ordering or subcontracting of items. These controllable variables constitute pure strategies by which fluctuations in demand and uncertainties in production activities can be accommodated by using the following steps:

1. Vary the size or the workforce: Output is controlled by hiring or laying off workers in proportion to changes in demand.

2. Vary the hours worked: Maintain the stable workforce, but permit idle time when there is a slack and permit overtime (OT) when demand is peak.

3. Vary inventory levels: Demand fluctuations can be met by large amount of inventory.

4. Subcontract: Upward shift in demand from low level. Constant production rates can be met by using subcontractors to provide extra capacity.

Aggregate Planning Guidelines

The following are the guidelines for aggregate planning:

1. Determine corporate policy regarding controllable variables.

2. Use a good forecast as a basis for planning.

3. Plan in proper units of capacity.

4. Maintain the stable workforce.

5. Maintain needed control over inventories.

6. Maintain flexibility to change.

7. Respond to demand in a controlled manner.

8. Evaluate planning on a regular base.

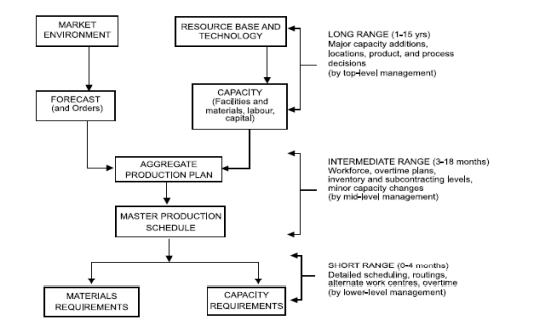

4.4 MASTER PRODUCTION SCHEDULE (MPS)

Master scheduling follows aggregate planning. It expresses the overall plans in terms of specific end items or models that can be assigned priorities. It is useful to plan for the material and capacity requirements. Flowchart of aggregate plan and master production schedule is shown in Fig. 5.4 Time interval used in master scheduling depends upon the type, volume, and component lead times of the products being produced. Normally weekly time intervals are used. The time horizon covered by the master schedule also depends upon product characteristics and lead times. Some master schedules cover a period as short as few weeks and for some products it is more than a year.

Functions of MPS

Master Production Schedule (MPS) gives a formal details of the production plan and converts this plan into specific material and capacity requirements. The requirements with respect to labour, material and equipment is then assessed.

The main functions of MPS are:

1. To translate aggregate plans into specific end items: Aggregate plan determines level of operations that tentatively balances the market demands with the material, labour and equipment capabilities of the company. A master schedule translates this plan into specific number of end items to be produced in specific time period

Fig. 1.4 Flowchart of aggregate plan and master schedule

2. Evaluate alternative schedules: Master schedule is prepared by trial and error. Manycomputermsimulation models are available to evaluate the alternate schedules.

3. Generate material requirement: It forms the basic input for material requirement planning

(MRP).

4. Generate capacity requirements: Capacity requirements are directly derived from MPS.

Master scheduling is thus a prerequisite for capacity planning.

5. Facilitate information processing: By controlling the load on the plant. Master schedule determines when the delivery should be made. It coordinates with other management information systems such as, marketing, finance and personnel.

6. Effective utilization of capacity: By specifying end item requirements schedule establishes the

load and utilization requirements for machines and equipment.

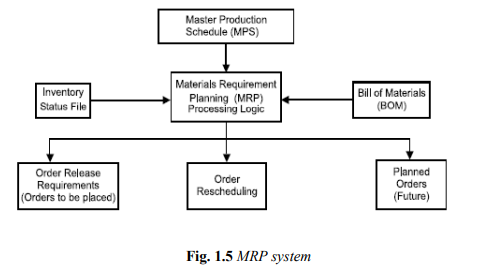

4.5 MATERIAL REQUIREMENT PLANNING (MRP)

MRP refers to the basic calculations used to determine components required from end item requirements. It also refers to a broader information system that uses the dependence relationship to plan and control manufacturing operations.

“Materials Requirement Planning (MRP) is a technique for determining the quantity and timing for the acquisition of dependent demand items needed to satisfy master production schedule requirements.”

Objectives of MRP

1. Inventory reduction: MRP determines how many components are required when they are required in order to meet the master schedule. It helps to procure the materials/ components as and when needed and thus avoid excessive build up of inventory.

2. Reduction in the manufacturing and delivery lead times: MRP identifies materials and component quantities, timings when they are needed, availabilities and procurements and actions required to meet delivery deadlines. MRP helps to avoid delays in production and priorities production activities by putting due dates on customer job order.

3. Realistic delivery commitments: By using MRP, production can give marketing timely information about likely delivery times to prospective customers.

4. Increased efficiency: MRP provides a close coordination among various work centres and hence help to achieve uninterrupted flow of materials through the production line. This increases the efficiency of production system.

MRP System

The inputs to the MRP system are: (1) A master production schedule, (2) An inventory status file and (3) Bill of materials (BOM).

Using these three information sources, the MRP processing logic (computer programme) provides three kinds of information (output) for each product component: order release requirements, order rescheduling and planned orders.

1. Master Production Schedule (Mps)

MPS is a series of time phased quantities for each item that a company produces, indicating how many are to be produced and when. MPS is initially developed from firm customer orders or from forecasts of demand before MRP system begins to operate. The MRP system whatever the master schedule demands and translates MPS end items into specific component requirements. Many systems make a simulated trial run to determine whether the proposed master can be satisfied.

2. Inventory Status File

Every inventory item being planned must have an inventory status file which gives complete and up to date information on the on-hand quantities, gross requirements, scheduled receipts and planned order releases for an item. It also includes planning information such as lot sizes, lead times, safety stock levels and scrap allowances.

3. Bill Of Materials (Bom)

BOM identifies how each end product is manufactured, specifying all subcomponents items, their sequence of build up, their quantity in each finished unit and the work centres performing the build up sequence. This information is obtained from product design documents, workflow analysis and other standard manufacturing information

REVIEW QUESTIONS

i. What do you mean by aggregate planning?

ii. Discuss the operations planning and scheduling systems.

iii. Discuss the aggregate plan and master schedule.

iv. Discuss the MRP system and explain the objective of MRP.

v. Explain the functions of master production schedule