CHAPTER TWO: OPERATION MANAGEMENT

2.1 A FRAMEWORK FOR MANAGING OPERATIONS

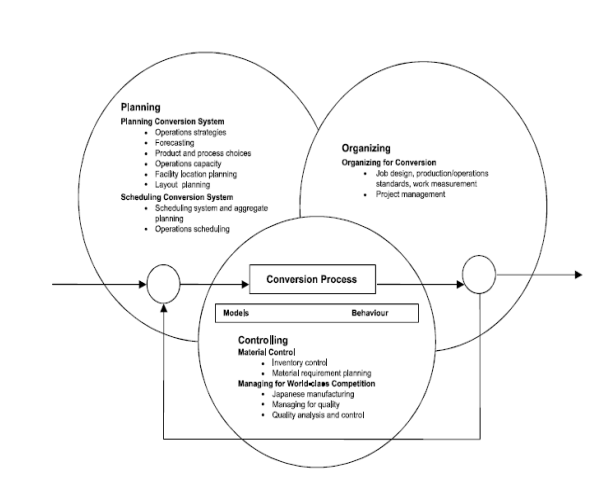

Managing operations can be enclosed in a frame of general management function as shown below in Fig. 2.1. Operation managers are concerned with planning, organizing, and controlling the activities which affect human behavior through models.

Planning

Activities that establishes a course of action and guide future decision-making is planning. The operations manager defines the objectives for the operations subsystem of the organization, and the policies, and procedures for achieving the objectives. This stage includes clarifying the role and focus of operations in the organization’s overall strategy. It also involves product planning, facility designing and using the conversion process.

Organizing

Activities that establishes a structure of tasks and authority. Operation managers establish a structure of roles and the flow of information within the operations subsystem. They determine the activities required to achieve the goals and assign authority and responsibility for carrying them out.

OBJECTIVES:

a) Framework for operation management.

b) The meaning and objectives of production and operation management.

c) The scope of production and operation management.

Controlling

Activities that assure the actual performance in accordance with planned performance. To ensure that the plans for the operations subsystems are accomplished, the operations manager must exercise control by measuring actual outputs and comparing them to planned operations management. Controlling costs, quality, and schedules are the important functions here.

Behaviour

Operation managers are concerned with how their efforts to plan, organize, and control affect human behavior. They also want to know how the behavior of subordinates can affect management’s planning, organizing, and controlling actions. Their interest lies in decision making behavior.

Models

As operation managers plan, organize, and control the conversion process, they encounter many problems and must make many decisions. They can simplify their difficulties using models like aggregate planning models for examining how best to use existing capacity in short-term, break even analysis to identify break even volumes, linear programming and computer simulation for capacity utilizations, decision tree analysis for long-term capacity problem of facility expansion, simple median model for determining best locations of facilities etc

Fig 2.1 General model for managing operations

2.2 OBJECTIVES OF OPERATIONS MANAGEMENT

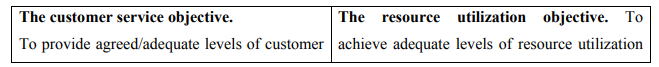

Objectives of operations management can be categorized into customer service and resource utilization.

Customer Service

The first objective of operating systems is the customer service to the satisfaction of customer wants. Therefore, customer service is a key objective of operations management. The operating system must provide something to a specification which can satisfy the customer in terms of cost and timing. Thus, primary objective can be satisfied by providing the ‘right thing at a right price at the right time’.

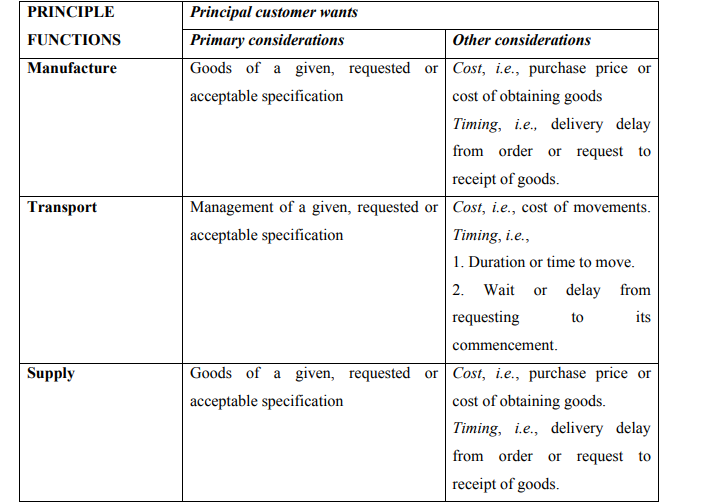

These aspects of customer service—specification, cost and timing—are described for four functions in Table 2.1. They are the principal sources of customer satisfaction and must, therefore, be the principal dimension of the customer service objective for operations managers.

Table2.1 Aspects of customer service

Generally an organization will aim reliably and consistently to achieve certain standards and operations manager will be influential in attempting to achieve these standards. Hence, this objective will influence the operations manager’s decisions to achieve the required customer service.

Resource Utilisation

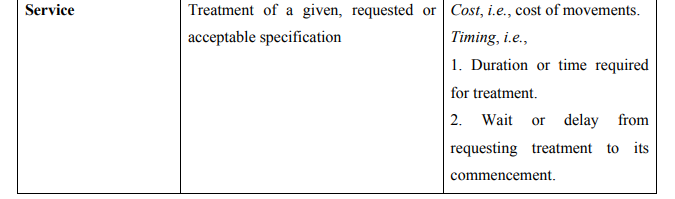

Another major objective of operating systems is to utilize resources for the satisfaction of customer wants effectively, i.e., customer service must be provided with the achievement of effective operations through efficient use of resources. Inefficient use of resources or inadequate customer service leads to commercial failure of an operating system.

Operations management is concerned essentially with the utilization of resources, i.e., obtaining maximum effect from resources or minimizing their loss, under utilization or waste. The extent of the utilizations of the resources’ potential might be expressed in terms of the proportion of available time used or occupied, space utilization, levels of activity, etc. Each measure indicates the extent to which the potential or capacity of such resources is utilized. This is referred as the objective of resource utilization.

Operations management is also concerned with the achievement of both satisfactory customer service and resource utilizations. An improvement in one will often give rise to deterioration in the other. Often both cannot be maximized, and hence a satisfactory performance must be achieved on both objectives.

Table 2.2 summarizes the twin objectives of operations management. The type of balance established both between and within these basic objectives will be influenced by market considerations, competitions, the strengths and weaknesses of the organization, etc. Hence, the operations managers should make a contribution when these objectives are set.

TABLE 2.2 The twin objectives of operations management

2.3 MANAGING GLOBAL OPERATIONS

The term ‘globalization’ describes businesses’ deployment of facilities and operations around the world. Globalization can be defined as a process in which geographic distance becomes a factor of diminishing importance in the establishment and maintenance of cross border economic, political and socio-cultural relations. It can also be defined as worldwide drive toward a globalize economic system dominated by supranational corporate trade and banking institutions that are not accountable to democratic processes or national governments.

There are four developments, which have spurred the trend toward globalization. These are:

1. Improved transportation and communication technologies;

2. Opened financial systems;

3. Increased demand for imports; and

4. Reduced import quotas and other trade barriers.

When a firm sets up facilities abroad it involves some added complexities in its operation. Global markets impose new standards on quality and time. Managers should not think about domestic markets first and then global markets later, rather it could be think globally and act locally. Also, they must have a good understanding of their competitors.

Some other important challenges of managing multinational operations include other languages and customs, different management style, unfamiliar laws and regulations, and different costs.

Managing global operations would focus on the following key issues:

To acquire and properly utilize the following concepts and those related to global operations, supply chain, logistics, etc.

To associate global historical events to key drivers in global operations from different

perspectives.

To develop criteria for conceptualization and evaluation of different global operations.

To associate success and failure cases of global operations to political, social, economical and technological environments.

To envision trends in global operations.

To develop an understanding of the world vision regardless of their country of origin, residence or studies in a respectful way of perspectives of people from different races, studies, preferences, religion, politic affiliation, place of origin, etc.

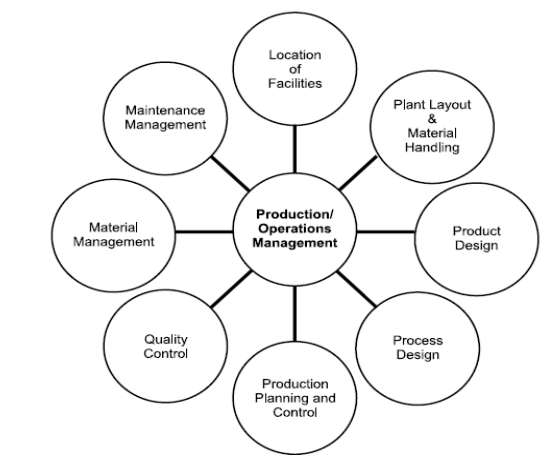

2.4 SCOPE OF PRODUCTION AND OPERATIONS MANAGEMENT

Production and operation management are concerned with the conversion of inputs into outputs, using physical resources, so as to provide the desired utilities to the customer while meeting the other organizational objectives of effectiveness, efficiency and adoptability. It distinguishes itself from other functions such as personnel, marketing, finance, etc., by its primary concern for

‘conversion by using physical resources.’ Following are the activities which are listed under production and operations management functions:

1. Location of facilities

2. Plant layouts and material handling

3. Product design

4. Process design

5. Production and planning control

6. Quality control

7. Materials management

8. Maintenance management.

Location of Facilities

Location of facilities for operations is a long-term capacity decision which involves a long term commitment about the geographically static factors that affect a business organization. It is an important strategic level decision-making for an organization. It deals with the questions such as ‘where our main operations should be based?’

The selection of location is a key-decision as large investment is made in building plant and machinery. An improper location of plant may lead to waste of all the investments made in plant and machinery equipments. Hence, location of plant should be based on the company’s

expansion plan and policy, diversification plan for the products, changing sources of raw materials and many other factors. The purpose of the location study is to find the optimal location that will results in the greatest advantage to the organization.

Plant Layout and Material Handling

Plant layout refers to the physical arrangement of facilities. It is the configuration of departments, work centres and equipment in the conversion process. The overall objective of the plant layout is to design a physical arrangement that meets the required output quality and quantity most economically.

According to James Moore, “Plant layout is a plan of an optimum arrangement of facilities including personnel, operating equipment, storage space, material handling equipments and all other supporting services along with the design of best structure to contain all these facilities”. ‘Material Handling’ refers to the ‘moving of materials from the store room to the machine and from one machine to the next during the process of manufacture’. It is also defined as the ‘art and science of moving, packing and storing of products in any form’.

It is a specialized activity for a modern manufacturing concern, with 50 to 75% of the cost of production. This cost can be reduced by proper section, operation and maintenance of material handling devices.

Material handling devices increases the output, improves quality, speeds up the deliveries and decreases the cost of production. Hence, material handling is a prime consideration in the designing new plant and several existing plants.

Product Design

Product design deals with conversion of ideas into reality. Every business organization have to design, develop and introduce new products as a survival and growth strategy. Developing the new products and launching them in the market is the biggest challenge faced by the organizations.

The entire process of need identification to physical manufactures of product involves three functions: marketing, product development, and manufacturing. Product development translates the needs of customers given by marketing into technical specifications and designing the various features into the product to these specifications. Manufacturing has the responsibility of selecting the processes by which the product can be manufactured. Product design and development provides link between marketing, customer needs and expectations and the activities required to manufacture the product.

Process Design

Process design is a macroscopic decision-making of an overall process route for converting the raw material into finished goods. These decisions encompass the selection of a process, choice of technology, process flow analysis and layout of the facilities. Hence, the important decisions in process design are to analyze the workflow for converting raw material into finished product and

to select the workstation for each included in the workflow. Production Planning and Control Production planning and control can be defined as the process of planning the production in advance, setting the exact route of each item, fixing the starting and finishing dates for each item, to give production orders to shops and to follow up the progress of products according to orders.

The principle of production planning and control lies in the statement ‘First Plan Your Work and then Work on Your Plan’. Main functions of production planning and control includes planning, routing, scheduling, dispatching and follow-up.

Planning is deciding in advance what to do, how to do it, when to do it and who is to do it. Planning bridges the gap from where we are, to where we want to go. It makes it possible for things to occur which would not otherwise happen. Routing may be defined as the selection of path which each part of the product will follow, which being transformed from raw material to finished products. Routing determines the most advantageous path to be followed from department to department and machine to machine till raw material gets its final shape.

Scheduling determines the programme for the operations. Scheduling may be defined as ‘the fixation of time and date for each operation’ as well as it determines the sequence of operations to be followed.

Fig.2.2 Scope of production and operations management

Dispatching is concerned with the starting the processes. It gives necessary authority so as to start a particular work, which has already been planned under ‘Routing’ and ‘Scheduling’. Therefore, dispatching is ‘release of orders and instruction for the starting of production for any item in acceptance with the route sheet and schedule charts’.

The function of follow-up is to report daily the progress of work in each shop in a prescribed proforma and to investigate the causes of deviations from the planned performance.

Quality Control

Quality Control (QC) may be defined as ‘a system that is used to maintain a desired level of quality in a product or service’. It is a systematic control of various factors that affect the quality of the product. Quality control aims at prevention of defects at the source, relies on effective feed back system and corrective action procedure.

Quality control can also be defined as ‘that industrial management technique by means of which product of uniform acceptable quality is manufactured’. It is the entire collection of activities which ensures that the operation will produce the optimum quality products at minimum cost.

The main objectives of quality control are:

To improve the companies income by making the production more acceptable to the customers i.e., by providing long life, greater usefulness, maintainability, etc.

To reduce companies cost through reduction of losses due to defects.

To achieve interchangeability of manufacture in large scale production.

To produce optimal quality at reduced price.

To ensure satisfaction of customers with productions or services or high quality level, to

build customer goodwill, confidence and reputation of manufacturer.

To make inspection prompt to ensure quality control.

To check the variation during manufacturing.

Materials Management

Materials management is that aspect of management function which is primarily concerned with the acquisition, control and use of materials needed and flow of goods and services connected with the production process having some predetermined objectives in view.

The main objectives of materials management are:

To minimize material cost.

To purchase, receive, transport and store materials efficiently and to reduce the related cost.

To cut down costs through simplification, standardization, value analysis, import substitution, etc.

To trace new sources of supply and to develop cordial relations with them in order to ensure continuous supply at reasonable rates.

To reduce investment tied in the inventories for use in other productive purposes and to develop high inventory turnover ratios.

Maintenance Management

In modern industry, equipment and machinery are a very important part of the total productive effort. Therefore, their idleness or downtime becomes are very expensive. Hence, it is very important that the plant machinery should be properly maintained.

The main objectives of maintenance management are:

1. To achieve minimum breakdown and to keep the plant in good working condition at the lowest possible cost.

2. To keep the machines and other facilities in such a condition that permits them to be used at their optimal capacity without interruption.

3. To ensure the availability of the machines, buildings and services required by other sections of the factory for the performance of their functions at optimal return on investment.

REVIEW QUESTION

1. Explain in brief the objectives of operations management.

2. Distinguish between manufacturing operations and service operations.

3. Explain the key issues to be considered for managing global operations

4. Explain the framework of managing operations.

5. Explain the scope of production and operations management.