Materials requirements planning (MRP) developed during the 1970s but is equally applicable today. It operates as an integrated information management, production planning and stock management system that has been enhanced in practicality in recent years as the speed and power of IT systems have increased. MRP is also known as MRPI. This differentiates it from manufacturing resources planning (MRPII).

MRP enables the advance planning of materials required for manufacture. The system utilizes a bill of materials (BOM), in essence a breakdown of all the materials and components that go to make a finished product. The BOM serves to inform purchasing that goods must be ordered to meet an anticipated manufacturing date. Purchasing will then order, taking into account the suppliers lead times

and a „safety margin‟ ( it is not a just in time system but works to allow a practical margin for error, i.e. . an agreed number of days in advance of production). The objective is to ensure that when production commences the goods are available as required and that inventory levels are minimized.

MRP is defined as „a set of logically related procedures, decision rules, and records designed to relate a master production schedule (MPS) into time-phased „net requirements‟ for each component inventory item needed to implement this schedule‟. The elements of this definition are examined below.

- A set of logically related procedures: MRP systems follow a logical sequence that incorporates decision rules relating to existing stock held, forecasting etc.

- Translate an MPS into time phased ‘net requirements’: time-phased because not everything is required at the same time. If the manufacturing run is extending over six days it may not be until the final day that you require a particular component. By getting

delivery later than when the run commenced inventory cost savings can be made. We refer to „net requirements‟ because the MRP system takes into account that you may already hold some of the required stock items in stock and will reduce the ordered

quantity accordingly. - The planned coverage of such requirements for each component inventory item needed to implement this schedule; ensuring that each item is required, taking into account suppliers lead times, is ordered accordingly.

Principles of MRP

An MRP system is a dependent demand system. E.g. suppose we are making 5000 square framed print. You require four pieces of wood cut to the same length and shape for each frame- a total of 20,000 pieces of wood. You require 5000 pieces of glass to fit the frame. The number of parts you require is dependent on the number of finished items to be produced. The approach of materials requirement planning to dependent demand is to start from the end and work backwards. The first step is to estimate customer demand for a finished product, and then calculate a production schedule to meet that demand. Customer demand will usually include orders received together with forecast estimates of additional customer demand.

Forecasting is important as it enables longer production runs to be undertaken, thereby gaining in reduced set up times and economies of scale, where either future sales are predicted or where a justifiable case for manufacturing for stock has been accepted.

The main elements of an MRP system These include: a bill of materials, a master schedule, and an inventory records file.

1. The master production schedule

Both forecast demand and actual demand on hand are combined in the MPS to decide the quantity to be produced. The role of the MPS is crucial in the MRP system. It provides the specification of the work to be progressed. Linking with the manufacturing availability in the capacity requirements plan (CRP) it brings together what is to be made, assembled or bought in within a specific time frame. The MPS enables us to plan the utilization of both labor and equipment. In turn, this identifies to the purchasing department when delivery is required from the suppliers to meet production run requirements. The MPS is in effect a summary of customer demand. The MRP program acts on the MPS as follows.

- By reference to the BOM file the program translates details of finished products required into details of materials and components required.

- By reference to the stock file program compares what is required with what is in stock

The outputs from the program specify not just the amounts required in this process but also the time by which it is required. They also highlight the need for any special action, such as the possible need to re-schedule or expedite orders.

Detailed outputs of the system will include any or all of the following;

• Order releases to purchasing for the current period, including the dates when required

• Planned order releases to purchasing for future periods, based on current stocks, orders in progress, scheduled requirements and known lead times.

• Order releases for items to be produced in-house, with due dates for completion.

• Feedback on problems such as bottlenecks or lack of availability. This allows schedulers to make adjustments that can be incorporated in the revised program run.

2. The Bill of Materials

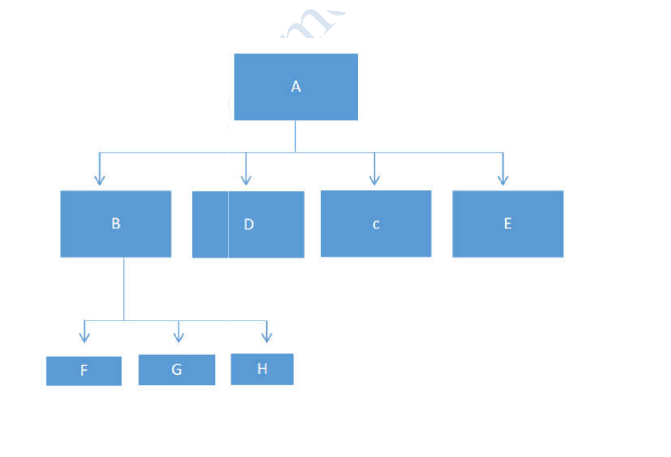

This is a listing of all the raw materials, component parts, subassemblies, and assemblies required to produce one unit of a specific finished product. Each different product made by a given manufacturer will have its own separate bill of materials. The bill of materials is arranged in a hierarchy, so that managers can see what materials are needed to complete each level of production. MRP uses the bill of materials to determine the quantity of each component that is needed to produce a certain number of finished products. From this quantity, the system subtracts the quantity of that item already in inventory to determine order requirements.

The above diagram illustrates a bill of materials for product A. Product A is made of Assembly B, Components C and D and Material E. Assembly B is made from materials F and G, and component H (as well as other assemblies or products). This analysis is continued until it captures all the materials, components etc. that are used in manufacture of Product A.

A typical BOM will contain the following items of information.

• Quantity required. The quantity required is one of the most important parts of the BOM because it tells us how many parts are needed for the product.

• Item Identification Number. This tells us which part to order. It can be a catalogue number, unique product code, or any other identification number.

• Description of the item. This provides a check that the correct item is being ordered.

• Cost. This is included to show how much each part is per item and the total cost of all like parts.

• Total product cost.

3. Inventory data

Accurate inventory records are a fundamental requirement of an MRP system. We need to know our „net requirements‟. E.g. if we need 1000 units of X and we hold 300 units in stock, our „net requirement‟ would be 800 units, allowing for the agreed ‟safety stock‟.

MRP requires inventory records that describe:

• Each item of stock (part number, part description, supplier’s lead time for supply). The information is held on the item master file and requires regular review particularly with regard to supplier lead times.

• Stock location, which is normally held on a location file following delivery. This will often form part of an integrated system covering storage and distribution in this instance.

• Transaction records relating to each stock item. This information is stored on a transaction file and may be linked to a purchasing management system such as SAP or Oracle.

Applications of MRP

While having elements in common to all inventory situations, MRP is most applicable where:

• The demand for an item is dependent

• The demand is discontinuous-lumpy and non-uniform

• In job, batch and assembly or flow production, or where all three manufacturing methods are used.

Benefits of an MRP system

• Provides accurate and timely information to purchasing staff

• A scheduling tool that it tells planners if due dates remain valid

• Anticipates shortages and/or slow moving stock

• Communicates priorities ( what is wanted and in what sequence)

• Professional and business discipline with the ability to build on and expand MRP system does not suit all organizations. It is a complex system to introduce and administer successfully. Once launched it may be difficult to make changes. While results are good in

batch production and some assembly processes, the application elsewhere is less straightforward.