Some firms make and buy critical nonstandard items to ensure that a reliable second source is available in case of difficulty with the supplier. Such a policy also provides data that are useful in reviewing internal production and management efficiency.

Making the Decision

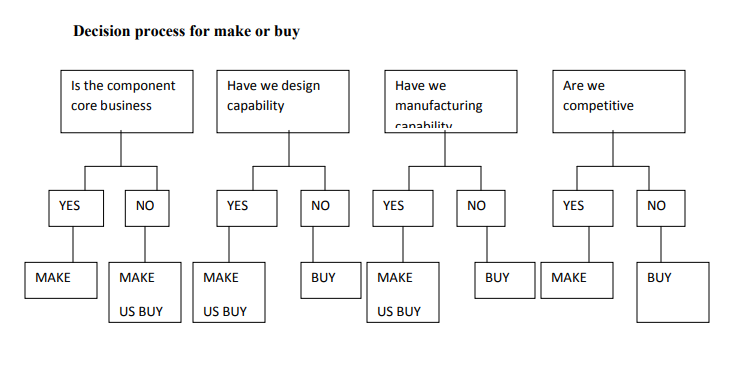

Make-or-buy decisions can have a critical effect on the economic health of a firm, even on its survival. Frequently, these decisions are made at too low a level in the organization. On many occasions, no conscious decision appears to have been made. Things just happen! The decision to make is often weaker than the decision to buy because buy costs are known whereas make costs are estimates.

Obviously, the amount of time and effort and the level of managerial attention appropriate are functions of the amount of money involved and the criticality of the item to the firm’s well-being. Normally several departments should be interested and involved in make-or-buy decisions: Production, Purchasing, Engineering, Finance, and Marketing.

Any of the following situations should precipitate a make-or-buy analysis:

- New product development and modification. Every major component should be reviewed.

- Unsatisfactory supplier performance. If purchasing is unable to develop reliable sources for an item, the item should be reviewed and analyzed to ensure that the specified quantity level is essential and to ensure that suitable substitutes are not available. If the item, as specified, passes these reviews, it becomes a candidate for in-house sourcing.

- Changes in sales. Sales demand that exceeds capacity calls for a make-or buy review of those items produced in house that contribute the lowest ROI. Declines in sales and production should prompt a review of candidates for in-house production.

- Periodic review of previous decisions. Changing costs and other considerations can convert a good make-or-buy decision into a bad one very quickly. Major make-or-buy decisions should be reviewed as a component of the firm’s annual planning process.