Introduction

- Poultry industry in Kenya has developed tremendously due to the use of artificial incubation and brooding and easy availability of hybrid birds, both eggers and broilers.

- Poultry production has become an easy source of income and food for the rural as well as the urban communities.

- The term poultry includes domestic birds such as turkeys, ducks, geese, pheasants, doves and pigeons.

- Of late ostrich farming has become a lucrative activity.

- Poultry production starts with incubation of eggs.

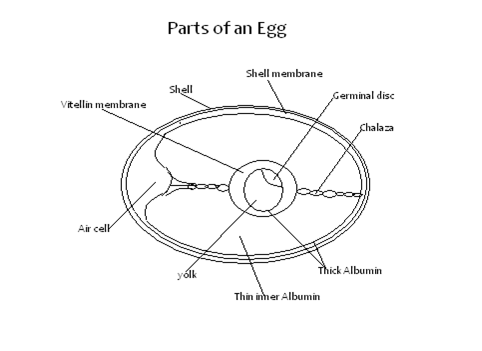

Parts of an Egg

Shell

- Forms 10-12% of the whole egg content.

- Made of calcium and phosphorus.

- Protects the inner egg contents.

Shell membrane

- Made of inner and outer membranes.

- Lining of the egg shell.

- Constitutes 1 % of the total egg content.

Albumen (egg white)

- About 55-60% of the total egg content.

- It is divided into chalaza, thick and thin albumen.

- Chalaza holds the egg yolk in position.

- Albumen serves as food for the chick.

Yolk

- 30-33% of the total egg content.

- Supply embryo with nutrient

Germinal disc -The embryo which develops into a chick if fertilized.

Vitelline membrane – Gives the yolk its round shape.

- Air sac

- Keeps the egg fresh by allowing gaseous exchange.

- Provides oxygen for the embryo

Egg Candling:

- This is the practice of determining the internal qualities of an egg by examining it against a light source.

Procedure

- The egg is placed on a hole made on a .cardboard box.

- This is called a candling box.

- A source of light is placed in the box directly under the egg.

- The observer then looks through the egg against the source of light below.

- Abnormalities on and within the egg can be seen through the translucent shell.

Incubation

- Involves the provision of fertile eggs with the proper condition for embryonic development.

Selection of Eggs for Incubation

- Should be fertile.

- Should be of medium size about 55- 60gms in weight.

- Should have smooth shell.

- Should be oval shaped.

- Should not be cracked.

- Eggs should be clean to ensure that pores are open.

- Should not have abnormalities such as blood spots, meat spots and double yolk. .

- Eggs should not be more than 5 days old.

- Eggs should be fresh that is collected within one week.

Internal egg qualities can be determined through the egg candling process.

Methods of Incubation

Natural Incubation

- This involves the use of a broody hen which sits on the eggs to provide them with conditions necessary for hatching.

- Takes 20-21 days.

- The hen is given about 10-15 eggs.

Signs‘ of Broodiness in Poultry

- Tendency to sit on an egg after laying.

- Moulting of the hen.

- Making some noise at the laying nests.

- Feathers are raised.

- It becomes aggressive when disturbed.

- It stops laying.

Preparation and Management of Natural Incubation

- The hen is given “China eggs” to sit on to induce broodiness.

- When broody the hen should be provided with a nesting nest or a saucershaped nest scooped on the ground.

- The nest shall be lined with soft bedding and fertile eggs provided.

- The eggs are set in the evening or night.

- The bird is dusted to control external parasites.

- The hen is allowed t hour outside to feed and exercise everyday.

- Broken eggs should be removed immediately.

- The hen should not be disturbed.

Advantages of Natural Incubation

- It is cheap.

- High hatchability.

- Low risk involved.

- Useful in small scale production.

- Less skill is required.

- Less laborious.

Disadvantages of Natural Incubation

- Egg production is low because the hen will not lay eggs during incubation.

- It is not possible to plan when to incubate.

- If the hen dies the eggs will be destroyed.

- If the hen deserts the eggs or refuses to sit on them the farmer will incur losses.

- Only few chicks can be hatched at a time by one hen.

- Diseases and parasites could easily be transmitted to the chicks.

Artificial Incubation

- This is the use of artificial device known as an incubator for hatching eggs.

Conditions Necessary for Artificial Hatching of Eggs

- Temperature – maintain at 37.5°C-39.4 °C throughout to control the rate of embryonic development of the chick. High or low temperatures are lethal.

- Ventilation – Good air circulation.

- Carbon dioxide: oxygen ratio maintained at 0.03%:21 %.

- Relative humidity – Maintained at 60%.

- High humidity leads to marshy chicks

- low humidity the chick may stick to the shell.

Turning of Eggs –

- Done 3-4 times a day to facilitate uniform distribution of heat for uniform development of chick.

- Turn slowly 180 ° clockwise along the axis to avoid breaking the blood v

- Some incubators have automatic turning mechanism.

- Cleanliness – cleaning and disinfecting the incubator with formaldehyde solution.

Advantages of Artificial Incubation

- It facilitates large scale production of chicks.

- Incubators are always ready when needed.

- Artificial incubation leads to higher egg production because broodiness in the hens is not required, so there is more time for laying eggs.

Disadvantages of Artificial Incubation

- High initial capital in buying an incubator.

- High level of management and attention is required.

- It is not economical for only a small number of eggs.

- High risks involved in turning the eggs.

Brooding and Rearing of Chicks

- Brooding is the rearing of day old chicks upto 8 weeks old for the layer chicks and 2 weeks for the broiler chicks.

- For successful brooding the source of the chicks should be considered.

Sources of Chicks

The following factors should be considered:

- The reputation of the supplier (hatchery).

- Time taken by the chicks in transit.

- Proper sexing and breed identification.

Brooding

Natural Brooding

- A hen is allowed to take care of the chicks.

- She provides them with warmth and security.

- She stays with the chicks for 8 weeks and then rejects them.

Advantages

- It is cheap.

- Less labour is needed.

- Suitable for small scale.

Disadvantages of Natural Brooding

- Not possible to produce large numbers of chicks.

- The hen goes off laying during brooding time.

- Only possible when a broody hen is available.

Artificial Brooding

- The chicks are raised artificially in a structure known as a brooder until they are 8 weeks old.

Brooder Requirements

- Temperature – should be about 35°C in the 15th week and reduced to 21°C by the 8th week.

- Litter – wood shavings which are capable of absorbing 60% moisture without showing wetness should be used.

- Space confinement – Done by use of hardboards which are about 25cm high and form a circular space. A space of 1m2 for 25 chicks is required.

- Feeders and waterers – should be enough for the chicks and evenly distributed in the brooder.

- Ventilators – windows should be enough to allow proper air circulation but direct draught should be avoided.

Types of Heaters in the Brooder

- Electric heaters – one ordinary bulb 100 watts can raise 30 chicks.

- One infrared bulb 240 watts can raise 100 chicks.

- Kerosene burners – Hurricane lamps can raise 100 chicks.

- Charcoal burners – these are specially made jikos with heat deflectors.

Brooder Management

Preparation Before Chicks Arrive

- Start 2-3 days before arrival.

- The brooder house should be cleaned to remove old litter and then disinfected.

- New litters 5-1Ocm high should be put in and covered with absorbent materials/news papers.

- Equipment should be cleaned, disinfected and tested to make sure that they are working.

- The brooder is lit about 6 hours before the chicks arrive.

- Feed and water should be placed into shallow containers.

- Brooder space should be confined with a hard board to prevent chicks straying far from the source of heat.

Management After Arrival of the Chicks

- Chicks are placed in the brooder during the day to familiarize with the brooder.

- If chicks arrive stressed and weak they should be given glucose solution in the waterers.

- In case the heat source is charcoal burners they should be covered with wire mesh.

- Feed chicks with chick mash which is later mixed with growers mash as the chicks grow.

- Clean water should be provided and changed regularly.

- Constant attention should be given to the chicks for the first 2 weeks.

- Any vices should be checked and controlled.

- Any dead chicks should be removed as soon as seen.

- Ventilation should be used to control the temperature and humidity in the brooder.

- Constant disinfection is required at the entrance to avoid diseases.

- Brooder space should be increased as the chicks grow.

- Debeaking should be done at 10 days old.

- Vaccination against diseases such as Gumboro after 2 weeks, New Castle at 3-4 weeks and fowl typhoid at 7 weeks.

- Dusting to control external parasites.

- Growers’ mash should be introduced gradually at 7 weeks old.

- Chicks are removed from the brooder when they are 8 weeks old.

- On average the chick uses about 1.5kg – 2.2kg of chick mash by the time it is 8 weeks old.

Temperature Control in the Brooder

If the brooder temperatures are low the following should be done:

- Brooder space is reduced.

- Heaters are increased.

- Ventilators are closed.

If the brooder temperatures are too high the following should be done:

- Brooder space is increased.

- Heaters should be reduced.

- Ventilators should be opened.

Management of the Growers

- The growers are birds at the age of 9 weeks to the point of lay that is at 18 weeks.

- Growers should be fed on growers’

- By this time the growers should be occupying the main poultry house.

- Sick birds should be isolated and treated.

- A foot bath for constant disinfection should be placed at the entrance.

- Each bird is fed 115 gms per day of growers’ mash.

- Greens and soluble grit should also be provided.

- Clean water should be provided all the time (adilibitum).

- Drenching against internal parasites should be done by adding a dewormer into the water.

- Vermins should be controlled.

- Litter should be kept dry by turning.

- Vaccination should be done as required.

- Layer pullets require dimly lit house.

Management of the Layers

- Layers’ mash should be introduced at 18 weeks and increased gradually.

- The birds start laying at 18-21 weeks.

- The birds should be vaccinated against New Castle and fowl typhoid.

- Enough floor space roosts, feeders and waterers should be provided.

- Each hen should be given 120gms per day of layers’ mash.

- Clean water should be provided adlibitum.

- Eggs should be collected twice a day at noon and in the evening.

- Green leaves should be provided to keep the birds busy thus preventing cannibalism and improve the yellow colour of the yolk.

- Grains should be given in addition to the layers’ mash at the rate of 65gms per bird per day.

- Soluble grit or oyster shells should be provided at all times for efficient digestion and strong shelled eggs.

- Layers should be fed according to their body weight and the rate of egg production for example a 70kg bag should feed 100 layers for 4-5 days.

- Enough laying nests should be provided at least 1 per 5 layers.

- The laying boxes should be dimly lit to reduce egg eating.

- Debeaking should be done when necessary.

- Broken eggs and dead birds should be disposed off properly.

- The non-layers and cannibals should be culled.

Management of Broilers

- Broilers are table birds kept for meat production.

- They have high growth rates or high feed conversion ratio.

- The objective is to produce a kilogram of quality poultry meat from less than two kg of broiler feed.

- The broiler chick requires special broiler feed from day old to 4 weeks of age.

- Broiler starters’ mash or crumbs should be fed.

- This contains coccidiostat, high level of protein, vitamins and trace elements for early growth.

- From 4 weeks to 8 weeks they are given broiler follow-on mash or pellets.

- This feed contains high level of metabolisable energy to ensure a good cover of subcutaneous fat in the finished broiler.

- From 8 weeks until slaughter finisher pellets should be given to increase the size.

- Adequate clean water should be provided at all times (adlibitum).

- High level of hygiene should be maintained to reduce mortality rate.

- Birds should be dusted with appropriate pesticides to control external parasites.

- Deworming should be done routinely.

- Vaccination against common diseases should be done.

- Dead birds should be disposed off properly.

- Broilers should be kept under deep litter system, the house should be well ventilated and well lit.

Poultry Rearing Systems

- extensive,

- semi intensive

- intensive systems.

The Extensive Systems

Free Range

- Birds are set free throughout the day to fend for themselves.

- Birds are confined in night shelters for the night.

- There is no supplementation.

Advantages

- Birds eat insects and green leaves therefore less feed is required.

- Cheap method.

- Cannibalism and egg eating are reduced since the birds are not crowded.

- Manure is evenly spread in the runs.

- Low labour requirement.

- Birds get plenty of exercises thus helping to keep in good health.

- No need to provide grit as birds pick it from the soil.

Disadvantages

- More land is required if a farmer wants to rear many birds.

- Birds can be stolen or eaten by predators.

- Eggs get lost in the vegetation or stolen.

- Eggs get dirty.

- Difficult to determine layers from non-layers.

- Birds get easily infected with diseases and parasites of the area.

- Breeding programme is not easy to follow.

- Birds can destroy crops where perimeter fencing is not constructed.

- Low productivity per unit area.

Semi-Intensive

Fold System

- Birds are confined in small portable structures called folds.

- A fold measures 3.5m long, 1.5m wide and 1.5m height.

- 1/3 of the fold is roofed while the rest is enclosed with wire mesh.

- Birds get plenty of sunlight.

- Birds get fresh grass as the fold is moved to new grounds.

Advantages

- Manure is evenly spread in the field.

- Less feed is used because birds eat grass.

- Reduces build up of parasites and diseases since the fold is moved often.

- Birds are protected from predators.

Disadvantages

- Few birds are kept per fold.

- It is laborious since the folds are moved from one place to the other.

- Individual egg production record is difficult to keep.

- The fold does not last long because of

- high frequency of handling.

- The return per unit area of land is low.

Intensive System

Deep Litter System

- Birds are confined in a house throughout their life.

- The floor of the house is made up of litter which accumulates over time.

- Enough feeders, waterers and laying boxes are provided depending on the number of birds and space available.

- Movable roosts and perches made of timber frames should be provided in the house.

- Stress and vices should be watched closely and controlled.

- Eggs should be collected as frequently as possible to prevent dirt and egg eating.

- The house should be dimly lit.

- The floor space requirement should be 1m2 per 2-3 birds.

Advantages

- High stocking rate per unit area of land.

- Low labour requirement.

- Fast accumulation of manure.

- There is control of feeding, egg production and movement of birds.

- Safety of the birds is guaranteed from predators.

- No loss of eggs.

- Useful method when rearing breeding stock.

- Regular cleaning of the house is not necessary since the litter absorbs the droppings.

- Easy collection of eggs.

Disadvantages

- High incidence of cannibalism like egg eating, feather plucking and toe pecking.

- Pests and disease causing organisms accumulate in the litter.

- Individual records of the birds are not possible.

- May be difficult to find litter.

- Eggs become dirty if laid on the floor.

- Feeders and waterers may be contaminated by the litter.

- The system encourages broodiness in hens.

- High infestation of diseases if the management is below standard.

- If there is a disease outbreak, it can spread very quickly throughout the house due to the communal housing.

- High cost of building deep litter house.

Battery Cage System

- Birds are confined in cages which are placed in the poultry house.

- The cages are made of wire mesh

- Each cage contains 1-3 birds.

- Water and feed troughs together with eggs trays are fitted along the front side of the cages.

- The floor of the cages should be slanting to allow the eggs to roll out of the cages.

- Droppings from the cages fall from behind for easy cleaning.

Advantages

- Records are easily kept therefore culling is easy.

- Birds do not become broody.

- More eggs are collected due to restricted movement of the hens and complete control of egg eating.

- Tender meat is obtained from the culls because the muscles have not been toughened much.

- Handling is easier than in the other systems and individual attention to hens is given.

- Stocking rate is very high.

- Vices are greatly reduced.

- Eggs are clean because hens do not step on them.

- The system can easily be mechanised.

- Birds do not contaminate the food and water.

- Sick birds can be detected easily and isolated for treatment.

- Wire floors prevent re-infestation of parasitic worms and coccidiosis.

- No bullying during feeding.

- Low labour requirement.

Disadvantages

- Initial costs for cages, equipment and house are excessively high.

- Requires high level of management.

- Higher maintenance costs where automation is used.

- Birds may get fatigue due to lack of exercises thus lowering productivity.

- In case of disease outbreak, spreading is very fast.

- Birds develop bruises on combs, breasts and toes as they stick their necks out-to feed and walk in the cages.

- Not useful when rearing breeding stock and the rearing of broilers.

- Cannot be used for brooding young chicks.

Stress and Vices in Chicken

- Stress is a condition imposed on the birds making them disturbed and uncomfortable.

- Stress reduces production and brings about poor performance.

- Vices are habits developed by animals.

- These affect production and health of the birds.

- Usually they are bad habits.

Cause of Stress in Poultry

- Sudden changes in routine management.

- Presence of strangers in the poultry house.

- Presence of animals and vermins.

- Too much noise.

- Constant and poor handling.

- Sudden weather changes.

- Disturbance of the pecking order.

- Overcrowding

- Poor hygiene.

- Disease and pest attack.

- Lack of food and water.

Control of Stress

- Poultry house should be kept quiet and constructed away from noise.

- Poultry house should be insulated to maintain constant temperatures.

- Parasites and diseases should be controlled.

- Change in routine management should be gradual.

- Enough feed and water should be provided.

Vices

- Feather pecking.

- Cannibalism (toe and vent pecking).

- Egg eating.

Pecking and Cannibalism

- Situation where birds peck at each other resulting in death or injury.

Effects:

- Feather and body growth rate IS reduce

- Loss of birds due to death may result from cannibalism.

- Culling rate is increased (economic loss).

- The appearance of the carcass is spoiled thereby reducing its market value.

Causes of Cannibalism

- Overcrowding in the house.

- High temperatures in the poultry house making the birds uncomfortable.

- Too bright light.

- External parasite infestation.

- Inadequate and incorrect feeding.

- Idleness of the birds.

- Greediness of the birds.

- Disturbances of the pecking order.

- Prolapses of the rectum which occurs once in a while.

- Bright light in the lying boxes.

Preventive Measures

- Ample spacing should be provided on the floor, feeders, waterers and laying boxes.

- Overheating should be avoided during brooding.

- The house should be dimly lit for the layers.

- Laying nests should be darkened and above the groun

- Dusting should be done to control external parasites.

- Provide enough balanced ration.

- Birds should be kept busy.

- New/strange birds should not be allowed in the house.

Egg Eating

A vice influenced by the following:

- Presence of broken or soft shelled eggs.

- Idleness of the birds.

- Inadequate laying nests.

- Mineral deficiencies.

- Bright light in the laying nests.

- Greediness of the birds.

Preventive Measures

- Eggs should be collected regularly.

- Laying boxes raised above the ground.

- Birds should be given balanced ration.

- Debeaking should be done as need be.

- Birds should be kept busy with greens.

- Birds should be kept according to age groups.

- Injured birds should be isolated and treated.

Marketing of Poultry Products

- Poultry products include eggs and meat.

Marketing of Eggs

- Eggs are delicate and perishable foods and have the highest value when fresh.

The factors considered when sorting out and grading eggs for the market include:

- Size/weight of the egg – large eggs fetch high prices than small ones. The average weight should be about 57gms.

- Shape of the egg – The normal egg shape is oval, with a broad end and a narrow end.

- Cleanliness – Consumers prefer clean eggs.

- Colour of the shell – Brown eggs are popular with the consumers.

- Candling qualities – candling is done to determine freshness of the eggs and presence of any other egg abnormalities.

- Shell texture – should be smooth and without cracks.

Poultry Meat

- Broilers are slaughtered at the age of 1-2.5months old with a life weight of 1.5-2kgs.

- The birds are killed and dressed in a clean way before being wrapped in clean bags ready for sale.

- The meat is sold in hotels and restaurants.

- Whole birds can be sold live in local markets.