Basic Elements of lean production

Flexible resources

Multifunctional workers who perform more than one job and general-purpose machines which perform several basic functions

Cycle time-time required for the worker to complete one pass through the operations assigned paces production to customer demand.

Cellular layouts

Manufacturing cells comprised of dissimilar machines brought together to manufacture a family of parts and cycle time is adjusted to match takt time by changing worker paths.

Pull system

Material is pulled through the system when needed and reversal of traditional push system where material is pushed according to a schedule, forces cooperation, prevent over and underproduction while push systems rely on a predetermined schedule, pull systems rely on customer requests

Kanbans

This is a card which indicates standard quantity of production. It is derived from two-bin inventory system which maintains discipline of pull production. It authorizes production and movement of goods.

Types of Kanbans

Production kanban-It authorizes production of goods

Withdrawal kanban-It authorizes movement of goods

Kanban square-This is a marked area designated to hold items

Signal kanban-This is a triangular kanban used to signal production at the previous workstation.

Material kanban-This is used to order material in advance of a process

Supplier kanban-This rotates between the factory and suppliers

Small lots

Require less space and capital investment to move processes closer together and makes quality problems easier to detect and processes more dependent on each other.

Quick setups

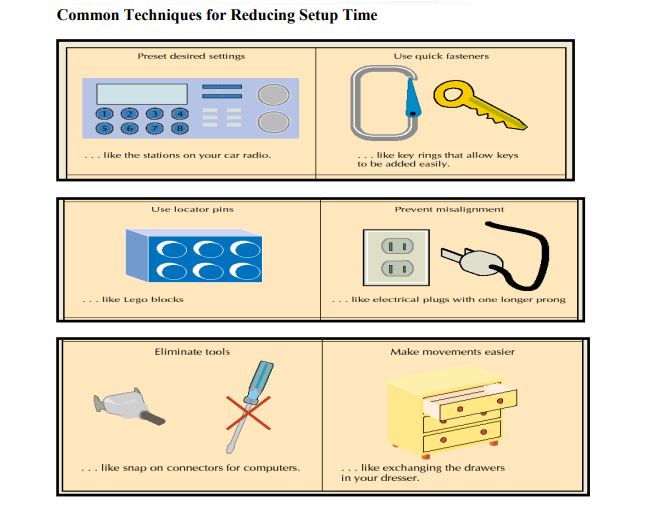

Internal setup-This Can be performed only when a process is stopped

External setup-This Can be performed in advance

Uniform production levels

- Result from smoothing production requirements on final assembly line

- Kanban systems can handle +/- 10% demand changes

- Reduce variability with more accurate forecasts

- Smooth demand across planning horizon

- Mixed-model assembly steadies component production

Quality at the source

This can be achieved by;

- Visual control-makes problems visible

- Poka-yokes—This prevent defects from occurring

- Kaizen-This is a system of continuous improvement; ―change for the good of all‖

- Jidoka-authority to stop the production line

- Andons-call lights that signal locations of quality problems

- Under-capacity scheduling-This leaves time for planning, problem solving, and maintenance

Total productive maintenance

This can be achieved by;

- Breakdown maintenance-Repairs to make failed machine operational

- Preventive maintenance-System of periodic inspection and maintenance to keep machines operating

TPM combines preventive maintenance and total quality concepts

TPM Requirements

- Design products that can be easily produced on existing machines

- Design machines for easier operation, changeover, and maintenance

- Train and retrain workers to operate machines

- Purchase machines that maximize productive potential

- Design preventive maintenance plan spanning life of machine

Supplier networks

This can be achieved by;

- Long-term supplier contracts

- Synchronized production

- Supplier certification

- Mixed loads and frequent deliveries

- Precise delivery schedules

- Standardized, sequenced delivery

- Locating in close proximity to the customer

JIT

Just-in-time (JIT) manufacturing, also known as just-in-time production or the Toyota production system (TPS) is a methodology aimed primarily at reducing flow times within production as well as response times from suppliers and to customers. It allows companies to reduce their overhead expenses while always ensuring that parts are available to manufacture their products.

Benefits of JIT

- Lower Warehouse Costs

Storing excess inventory can cost a lot of money, and reducing the amount of inventory you keep on hand can reduce your carrying costs as well. Companies that implement the just-in time inventory model may be able to reduce the number of warehouses they maintain, or even allow them to eliminate those warehouses altogether. - Better Supply Chain Management

The just-in-time inventory model can also help companies be more efficient and competitive in the way they handle their supply chains and use their parts to assemble products for their customers. A more efficient supply chain can provide lower costs throughout the manufacturing process, and those lower costs can then be passed on to the customer. Those lower costs can make the company’s products more affordable, and help the company gain a larger market share and stay ahead of its competitors. - Better Customer Satisfaction

Implementing the just-in-time inventory management model can allow companies to serve their customers faster and more efficiently. Companies that use the just-in-time model have a greater level of control over the entire manufacturing process, making it easier to respond quickly when the needs of customers change. For instance, a computer manufacturer that uses

the just-in-time inventory control model can quickly ramp up production of a hot model, while reducing the number of unsold units and out-dated products. - Less Waste

When companies use the traditional method of inventory management and control, they can end up with pallets of unsold items that simply go to waste. The company many need to slash prices on that unsold inventory just to get rid of it, which can reduce the perceived value of the firm’s other products. The just-in-time inventory model reduces this waste and helps the company respond more quickly to what its customers need.

Disadvantages of JIT approach

- Faculty forecasting may lead to stock outs.

- JIT requires establishment of system to link p buyers of suppliers

- Lack of safety stocks makes the firm vulnerable to fail.

- Removes advantage of bill buying e.g. reduced prices.

- Requires much training to break down barriers between functions within the organization

Benefits of Lean Production

- Reduced inventory

- Improved quality

- Lower costs

- Reduced space requirements

- Shorter lead time

- Increased productivity

- Greater flexibility

- Better relations with suppliers

- Simplified scheduling and control activities

- Increased capacity

- Better use of human resources

- More product variety