CHAPTER ONE: INTRODUCTION TO PRODUCTION AND OPERATION

MANAGEMENT

1.1 INTRODUCTION

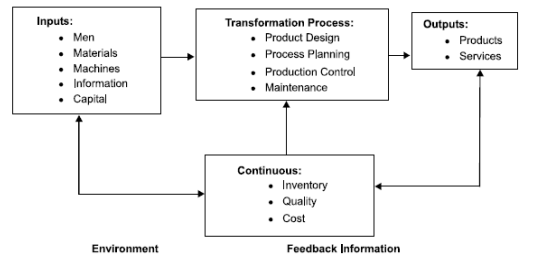

Production/operations management is the process, which combines and transforms various resources used in the production/operations subsystem of the organization into value added product/services in a controlled manner as per the policies of the organization.

Therefore, it is that part of an organization, which is concerned with the transformation of a range of inputs into the required (products/services) having the requisite quality level.

The set of interrelated management activities, which are involved in manufacturing certain products, is called as production management. If the same concept is extended to services management, then the corresponding set of management activities is called as operations

management.

1.2 HISTORICAL EVOLUTION OF PRODUCTION AND OPERATIONS

MANAGEMENT

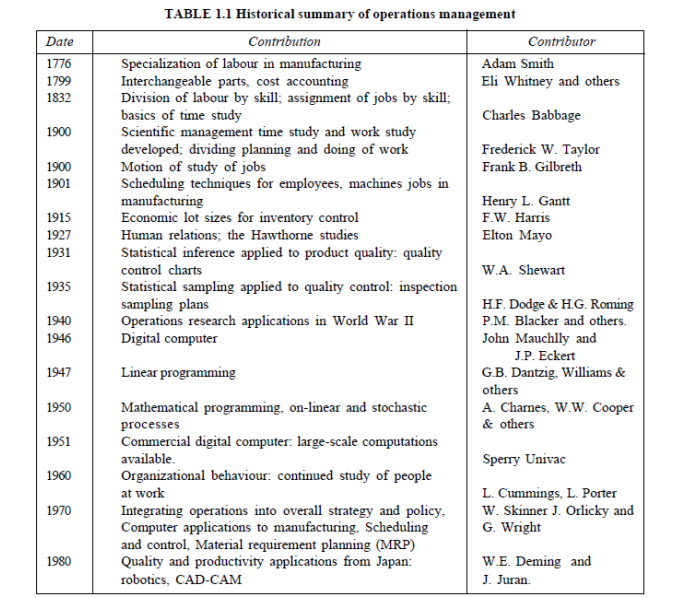

For over two centuries operations and production management has been recognized as an important factor in a country’s economic growth. The traditional view of manufacturing management began in eighteenth century when Adam Smith recognized the economic benefits of specialization of labour. He recommended breaking of jobs down into subtasks and recognizes workers to specialized tasks in which they would become highly skilled and efficient.

Objectives:

a) Introduction on production and operation management.

b) Key characteristics of production systems and the key classifications of production system.

c) Brief history of operation management

In the early twentieth century, F.W. Taylor implemented Smith’s theories and developed cientific management. From then till 1930, many techniques were developed prevailing the traditional view. Brief information about the contributions to manufacturing management is shown in the Table 1.1.

Production management becomes the acceptable term from 1930s to 1950s. As F.W. Taylor’s works become more widely known, managers developed techniques that focused on economic efficiency in manufacturing. Workers were studied in great detail to eliminate wasteful efforts and achieve greater efficiency. At the same time, psychologists, socialists and other social scientists began to study people and human behavior in the working environment. In addition, economists, mathematicians, and computer socialists contributed newer, more sophisticated analytical approaches. With the 1970s there emerged two distinct changes in our views. The most obvious of these, reflected in the new name operations management was a shift in the service and manufacturing sectors of the economy. As service sector became more prominent, the change from ‘production’ to ‘operations’ emphasized the broadening of our field to service organizations. The second, more suitable change was the beginning of an emphasis on synthesis, rather than just analysis, in management practices.

CONCEPT OF PRODUCTION

Production function is that part of an organization, which is concerned with the transformation of a range of inputs into the required outputs (products) having the requisite quality level. Production is defined as “the step-by-step conversion of one form of material into another form through chemical or mechanical process to create or enhance the utility of the product to the user.” Thus production is a value addition process. At each stage of processing, there will be value addition.

Edwood Buffa defines production as ‘a process by which goods and services are created’. Some examples of production are: manufacturing custom-made products like, boilers with a specific capacity, constructing flats, some structural fabrication works for selected customers, etc., and manufacturing standardized products like, car, bus, motor cycle, radio, television, etc.

Fig. 1.2 Schematic production system

Difference between Operations Management and Research

OR relies on mathematical modeling and OM relies on practical scenarios/industrial cases.

OR domain and tool of Engineers while OM is considered to be one of the critical tools of Managers.

OR considered more powerful to improve the whole system where as OM can be applied to a part of the system.

OR relies on mathematical modeling while OM relies on practical scenarios/industrial cases.

Key Areas of Responsibility for an Operations Manager

Operations Managers job responsibility includes but is not limited to:

Forecasting

Capacity planning

Scheduling

Inventory Management

Quality Assurance and Control

Motivating employees

Deciding where to locate facilities

1.4 PRODUCTION SYSTEM

The production system of an organization is that part, which produces products of an organization.

It is that activity whereby resources, flowing within a defined system, are combined and transformed in a controlled manner to add value in accordance with the policies communicated by management

The production system has the following characteristics:

1. Production is an organized activity, so every production system has an objective.

2. The system transforms the various inputs to useful outputs.

3. It does not operate in isolation from the other organization system.

4. There exists a feedback about the activities, which is essential to control and improve system performance.

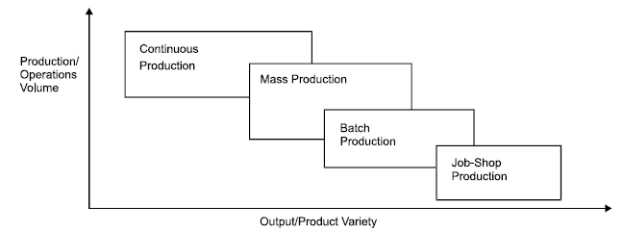

Classification of Production System

Production systems can be classified as Job Shop, Batch, Mass and Continuous Production systems.

Fig. 1.3 Classification of production systems

Job Shop Production

Job shop production are characterized by manufacturing of one or few quantity of products designed and produced as per the specification of customers within prefixed time and cost. The distinguishing feature of this is low volume and high variety of products.

A job shop comprises of general purpose machines arranged into different departments. Each job demands unique technological requirements, demands processing on machines in a certain sequence.

Characteristics

The Job-shop production system is followed when there is:

1. High variety of products and low volume.

2. Use of general purpose machines and facilities.

3. Highly skilled operators who can take up each job as a challenge because of uniqueness.

4. Large inventory of materials, tools, parts.

5. Detailed planning is essential for sequencing the requirements of each product, capacities for each work centre and order priorities.

Benefits

Following are the advantages of job shop production:

a. Because of general purpose machines and facilities variety of products can be produced.

b. Operators will become more skilled and competent, as each job gives them learning opportunities.

c. Full potential of operators can be utilized.

d. Opportunity exists for creative methods and innovative ideas.

Limitations

Following are the limitations of job shop production:

a. Higher cost due to frequent set up changes.

b. Higher level of inventory at all levels and hence higher inventory cost.

c. Production planning is complicated.

d. Larger space requirements.

Batch Production

Batch production is defined by American Production and Inventory Control Society (APICS) “as a form of manufacturing in which the job passes through the functional departments in lots or batches and each lot may have a different routing.” It is characterized by the manufacture of limited number of products produced at regular intervals and stocked awaiting sales.

Characteristics

Batch production system is used under the following circumstances:

1. When there is shorter production runs.

2. When plant and machinery are flexible.

3. When plant and machinery set up is used for the production of item in a batch and change

of set up is required for processing the next batch.

4. When manufacturing lead time and cost are lower as compared to job order production.

Benefits

Following are the advantages of batch production:

a. Better utilization of plant and machinery.

b. Promotes functional specialization.

c. Cost per unit is lower as compared to job order production.

d. Lower investment in plant and machinery.

e. Flexibility to accommodate and process number of products.

f. Job satisfaction exists for operators.

Limitations

Following are the limitations of batch production:

a. Material handling is complex because of irregular and longer flows.

b. Production planning and control is complex.

c. Work in process inventory is higher compared to continuous production.

d. Higher set up costs due to frequent changes in set up.

Mass Production

Manufacture of discrete parts or assemblies using a continuous process are called mass production.

This production system is justified by very large volume of production. The machines are arranged in a line or product layout. Product and process standardization exists and all outputs follow the same path.

Characteristics of mass production

Mass production is used under the following circumstances:

1. Standardization of product and process sequence.

2. Dedicated special purpose machines having higher production capacities and output rates.

3. Large volume of products.

4. Shorter cycle time of production.

5. Lower in process inventory.

6. Perfectly balanced production lines.

7. Flow of materials, components and parts is continuous and without any back tracking.

8. Production planning and control is easy.

9. Material handling can be completely automatic.

Advantages

Following are the advantages of mass production:

a. Higher rate of production with reduced cycle time.

b. Higher capacity utilization due to line balancing.

c. Less skilled operators are required.

d. Low process inventory.

e. Manufacturing cost per unit is low.

Limitations

Following are the limitations of mass production:

a. Breakdown of one machine will stop an entire production line.

b. Line layout needs major change with the changes in the product design.

c. High investment in production facilities.

d. The cycle time is determined by the slowest operation.

Continuous Production

Production facilities are arranged as per the sequence of production operations from the first operations to the finished product. The items are made to flow through the sequence of operations through material handling devices such as conveyors, transfer devices, etc.

Characteristics

Continuous production is used under the following circumstances:

1. Dedicated plant and equipment with zero flexibility.

2. Material handling is fully automated.

3. Process follows a predetermined sequence of operations.

4. Component materials cannot be readily identified with final product.

5. Planning and scheduling is a routine action.

Advantages

Following are the advantages of continuous production:

a. Standardization of product and process sequence.

b. Higher rate of production with reduced cycle time.

c. Higher capacity utilization due to line balancing.

d. Manpower is not required for material handling as it is completely automatic.

e. Person with limited skills can be used on the production line.

f. Unit cost is lower due to high volume of production.

Limitations

Following are the limitations of continuous production:

a. Flexibility to accommodate and process number of products does not exist.

b. Very high investment for setting flow lines.

c. Product differentiation is limited

1.5 PRODUCTION MANAGEMENT

Production management is a process of planning, organizing, directing and controlling the activities of the production function. It combines and transforms various resources used in the production subsystem of the organization into value added product in a controlled manner as per the policies of the organization.

E.S. Buffa defines production management as, “Production management deals with decision making related to production processes so that the resulting goods or services are produced according to specifications, in the amount and by the schedule demanded and out of minimum cost.”

Objectives of Production Management

The objective of the production management is ‘to produce goods services of right quality and quantity at the right time and right manufacturing cost’.

1. RIGHT QUALITY: The quality of product is established based upon the customers needs.

The right quality is not necessarily best quality. It is determined by the cost of the product and the technical characteristics as suited to the specific requirements.

2. RIGHT QUANTITY: The manufacturing organization should produce the products in right number. If they are produced in excess of demand the capital will block up in the form of inventory and if the quantity is produced in short of demand, leads to shortage of products.

3. RIGHT TIME: Timeliness of delivery is one of the important parameter to judge the effectiveness of production department. So, the production department has to make the optimal utilization of input resources to achieve its objective.

4. RIGHT MANUFACTURING COST: Manufacturing costs are established before the product is actually manufactured. Hence, all attempts should be made to produce the products at pre-established cost, so as to reduce the variation between actual and the standard (pre established) cost.

REVIEW QUESTIONS

1. What do you mean by ‘Production’?

2. What do you mean by production system?

3. What is batch production? What are its characteristics, advantages and limitations?

4. What is batch production? What are its characteristics, advantages and limitations?

5. What is mass production? What are its characteristics, advantages and limitations?

6. What is continuous production? What are its characteristics, advantages and limitations?

7. Explain in brief the objectives of production management.