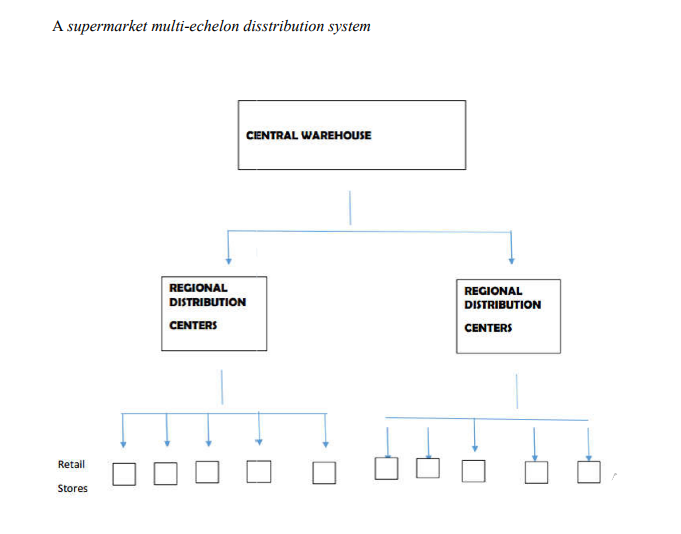

Distribution Requirements planning is an inventory control and scheduling technique that applies MRP principles to distribution inventories. It may also be regarded as a method of handling stock replenishment in multi-echelon environment. An echelon is defined as „A stepwise arrangement of troops, ships planes etc.

Applied to Distribution „multi-echelon‟ means that, instead of independent control of the same item at different distribution points using EOQ formulae, the dependent demand at a higher echelon( such as a higher central warehouse) is derived from the requirements off lower echelons( such as regional warehouses).

DRP is useful for both manufacturing organizations, such as car manufacturers that sell their cars via several distribution points, such as regional and local distributors, and purely merchandising organizations, such as supermarkets. All levels in a DRP multi echelon structure are dependent, except for the level that serves the customer, which are the retailers.

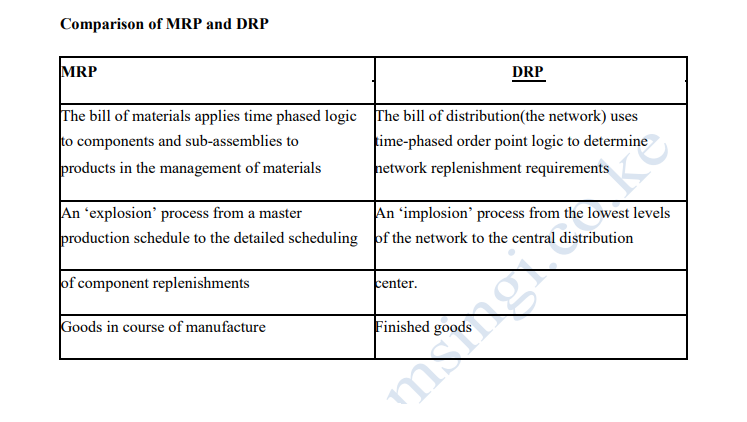

DRP and MRP similarities

- As planning systems , neither uses a fixed or periodic review approach

- Both are computerized systems

- Just as MRP has been expanded to MRPII, so has DRP been expanded to DRPII

- DRP utilizes record formats and processing logic consistent with MRP

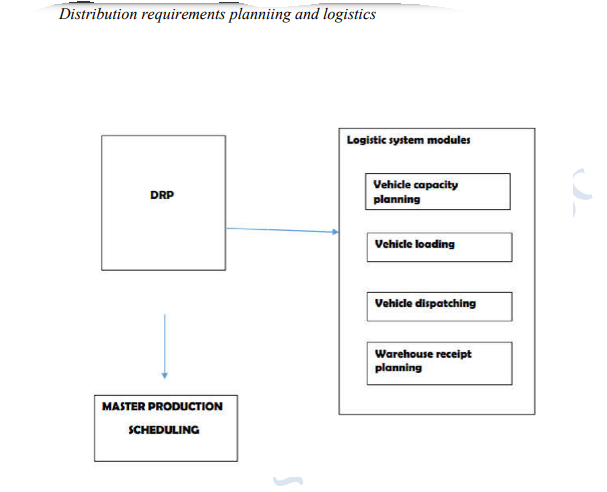

The last point is the most important of all as it provides the basis for integrating the database throughout the supply chain, from purchasing through to distribution. Thus, both MRP and DRP contribute to a logistics system.

Thus as Volman et al. observe:

Distribution Requirements planning serves a central role in coordinating the flow of goods inside the factory with the systems modules that place the goods in the hands of the customers. It provides the basis for integrating the manufacturing planning control (MRP) system from the firm to the field.