QUALITY ASSURANCE AND CONTROL

- Introduction to concepts in quality management:

Quality: ISO 8402 defines quality as the totality of features and characteristics of a product that bears on the ability to satisfy stated or implied needs. In this definition, features and characteristic of product ‘ implies the ability to identify what quality aspects can be measured, or controlled, or constitute an acceptable quality level (AQL) and ability to satisfy given needs relates to the value of the product or service to the customer including economic value as well as safety, reliability, maintainability and other relevant features.

Crosby defines quality as conformity to requirements not goodness. He also stresses that the definition of quality can never make any sense unless it is based on what the customer wants i.e. a product is a quality product only when it conforms to the customer’s requirements.

Juran defines quality as ‘fitness for use’. This definition implies quality of design, quality of conformance, availability and adequate field service. Garvin has identified five approaches to defining quality and eight dimensions of quality.

Five approaches of quality:

- The transcendent approach: quality is absolute and universally recognisable.

- The product-based approach: quality is precise and measurable variable.

- The user -based approach: quality is defined in terms of fitness for use or how well the product fulfils its intended functions

- The manufacturing-based approach: quality is conformance to specifications i.e. targets and tolerances determined by product designers.

- The value-based approach: quality is defined in terms of cost and prices. Here, a quality product is one that provides performance at an acceptable price or conformance at an acceptable cost.

Eight dimensions of quality:

- Performance: The product’s operating characteristics

- Reliability: The probability of a product surviving over a specified period of time under stated conditions of use.

- Serviceability: the speed, accessibility and ease of repairing the item or having it repaired.

- Conformance: The degree to which delivered products meet the pre determined standards.

- Durability: Measures the projected use available from the product over its intended operating cycle before it deteriorates.

- Features: ‘The bells and whistles’ or secondary characteristics which supplement the product the product’s basic functioning.

- Aesthetics: personal judgements of how a product looks, feels, sounds, tastes or smells.

- Perceived quality: Closely identified with the reputation of the producer. Like aesthetic, it is a personal evaluation.

Quality control and quality management-ISO 9000, 2000, TQM:

Quality control: Is concerned with defect detection and correction. Inspection activities can be classified as quality control processes, along with other activities which involve monitoring to ensure that defectives or potential defectives are spotted. Quality control can also be defined as a process employed to ensure certain level of quality or service. It may include whatever actions a business deems necessary to provide for the control and verification of certain characteristics of a product or service. The basic goal of quality control is to ensure that the products, service or processes provided meet specific requirements and are dependable, satisfactory and fiscally sound.

Quality assurance: Differs from quality control and is defined as all those planned and systematic activities implemented within the quality system and demonstrated as needed to provide adequate confidence that an entity will fulfil requirements for quality.

Quality assurance can also be defined as a planned and systematic production processes that provide confidence in a product’s suitability for its intended purpose. It can also be defined as a set of activities intended to ensure that products and services satisfy customer’s requirements in a systematic and reliable fashion.

Two key principles characteristics of quality assurance entail:’ fit for purpose’’ (the product should be suitable for the intended purpose) and ‘’right first time’’ (mistakes should be eliminated). Quality assurance include regulation of the quality of raw materials, assemblies, products, components, services related to production, management production and inspection processes.

Quality assurance is concerned with defect prevention and has become synonymous with quality systems such as Kenya bureau of standards (KEBS), BS5750 and international counterpart ISO 9000.

Quality assurance includes all activities connected with the attainment of quality such as:

- Design, including proving and testing

- Specification, which must be clear and unambiguous

- Assessment of supplier to ensure that they can perform

- Motivation of all concerned parties

- Education and training of supplier’s staff

- Inspection and testing

- Feedback to ensure that all measures are effective

Quality Assurance objectives:

- Reduction of errors and enhancement of quality

- Problem prevention rather than detection and correction

- Reduction in product or service costs

- Improved productivity

- Improved employee involvement, motivation, job satisfaction and commitment

- Improved teamwork and working relationships

- Development of employee problem-solving ability.

Advantages/ Importance of quality Assurance:

Both buyers and sellers gain benefits from a good quality control. The following are the principle advantages:

- Minimum possible rejection and wider acceptance of the supply is made possible by the supplier’s effective quality control system.

- Minimum inspection time and effort help the vendor as well as the purchase in delivery and receiving the supply at a lower cost

- Prospect of zero defects increase

- Scraps are minimised and wastage is reduced due to good quality assurance system

- Goodwill of both vendor and purchaser is enhanced as there are fewer difficult and problems in regard to quality products

- Sometimes inspection at the purchaser’s end is eliminated if vendor quality certificate and statistical date regarding the quality of the goods supplied is enclosed.

- Quality consciousness is developed resulting in benefit to all concerned.

- Accumulation of obsolete material is reduced to the minimum

- It results in reduction of lock-up capital due to decrease in inventory.

- KENYA BUREAU OF STANDARDS

The Kenya Bureau of Standards (KEBS) is a government agency responsible for governing and maintaining the standards and practices of metrology in Kenya. It was established by an Act of Parliament of Kenya’s National Assembly, The Standard Act, and Chapter 496 of the Laws of Kenya. The Bureau started its operations in July 1974. It has main offices in Nairobi, and regional offices throughout Kenya.[1]

The KEBS Board of Directors is known as the National Standards Council (“NSC”) and is the policy-making body for supervising and controlling the administration and financial management of the Bureau. The Bureau’s chief executive is the Managing Director.

The aims and objectives of KEBS include preparation of standards relating to products, measurements, materials, processes, etc. and their promotion at national, regional and international levels; certification of industrial products; assistance in the production of quality goods; quality inspection of imports at ports of entry; improvement of measurement accuracies and dissemination of information relating to standards.

To keep close liaison with and render efficient service to industry, trade and commerce in different parts of the country, KEBS has opened Regional Offices in Mombasa, Kisumu, Nakuru, Garissa, Nyeri and has import inspection offices at all the legal points of entry in Kenya.

ROLES OF KEBS

The functions of`KEBS are to:

- Promote standardisation in industry and commerce

- Provide facilities for testing and calibration of instruments and scientific apparatus and determine their degree of accuracy or issue of certificates

- Provide facilities for examination and testing of commodities, material or substance in which they may be manufactured, produced, processed or treated

- Control the use of standardisation and distinctive marks

- Prepare, frame, modify or amend specifications and codes of practice

- Help the Government, local authority, public institution or person in the preparation and framing of specifications or codes of practice

- Cooperate with the Government, representatives industry, local authority, public body or person in adopting and applying standards

- Provide testing services on behalf of the Government of locally manufactured and imported goods at the ports of entry or country of origin and determine whether goods comply with the law on standards of quality

- Test goods destined for export for purposes of export certification KEBS has approved a Kenyan Standard. It provides for common use, rules, guidelines or characteristics for products, services, processes and production methods aimed at achieving order

- lt may also deal exclusively with terminology, symbols, packaging, marking or labelling requirements on products, processes or production methods.

ISO – International Standards Organization

The Role of ISO and Its Affiliates

The International Standards Organization (ISO) is well known for its international management standards for quality assurance in a broad range of business and industrial applications. Generally these standards are referred to as ISO-90xx accreditations and they apply to corporations.

Approximately seven years ago, ISO and its state-level affiliates around the world established new standards, 17021 and 17024, for the certification of individual practitioners in various professional disciplines.

The American National Standards Institute (ANSI) is the state-level organization to which U.S. corporations apply for ISO accreditation.

Please note that, while this site refers to “ISO standards,” any formal reference is required to use the full name: ISO/ICE/ANSI Standard 17021 or 17024. For more on this, see: www.ansi.org

In addition to the steps listed in the Key Events graphic above, accreditation requires ongoing reports, audits and a range of other activities that are needed to ensure that this certification program is, and remains, current, comprehensive, effective, predictive, fair and secure.

The rigor involved in qualifying and maintaining ISO accreditation is the basis for our belief that State Regulators will approve this certification as one of the methods they use to test the theoretical knowledge of candidate

BENEFITS

Benefits of International Standards

International Standards bring technological, economic and societal benefits. They help to harmonize technical specifications of products and services making industry more efficient and breaking down barriers to international trade. Conformity to International Standards helps reassure consumers that products are safe, efficient and good for the environment.

Benefits of standards: the ISO Materials

ISO has developed materials describing the economic and social benefits of standards, the ISO Materials. They are intended to be shared with decision makers and stakeholders as concrete examples of the value of standards.

Facts and figures about the benefits of standards

The repository of studies on economic and social benefits of standards provides an insight of the approaches and results of the studies undertaken by different authors, such as national and international standards bodies, research institutes, universities and other international agencies.

For business

International Standards are strategic tools and guidelines to help companies tackle some of the most demanding challenges of modern business. They ensure that business operations are as efficient as possible, increase productivity and help companies access new markets.

Benefits include:

- Cost savings – International Standards help optimise operations and therefore improve the bottom line

- Enhanced customer satisfaction – International Standards help improve quality, enhance customer satisfaction and increase sales

- Access to new markets – International Standards help prevent trade barriers and open up global markets

- Increased market share – International Standards help increase productivity and competitive advantage

- Environmental benefits – International Standards help reduce negative impacts on the environment

- Globalisation

- Change with technology

- Ecologi conformanve

Businesses also benefit from taking part in the standard development process. Read more about the benefits of gettcb

Total quality management (TQM):

This is the overall management philosophy. TQM is defined as a way of managing an organisation so that every job, every process is carried out right, first time and every time. This mean each stage of process is carried out right, first time and every time. This also means that each stage of manufacture or service is 100% correct before it proceeds. TQM is also defined as an integrative management concept of continually improving the quality of delivered goods and services through the participation of all levels and functions of the organisation.

TQM principles:

TQM is based on three important tenets:

- A focus on product improvement from the customer’s view point. The term customer here is associated with concept of quality chains which emphasizes the linkages of suppliers and customers. Quality chains are both internal and external. Internally, purchasing is the customer of design and the supplier of production. Staffs within a function are also suppliers and customers.

- A recognition that personal at all levels share responsibility for product quality. It is based on team rather than individual performance. Thus, while top management provides leadership, continuous improvement is also understood and implemented at shop floor level (based on Japanese concept of Kaizen-on- going improvement which affects everyone). The characteristic s of this principle include:

- Provision of leadership from the top

- Creation of quality culture dedicated to continuous improvement

- Team-work- i.e. quality improvement teams and quality cycles

- Adequate resource allocation

- Quality training of employees

- Measurement and use of statistical concepts

- Quality feedback

- Employee recognition

It has been stated that ‘’once a culture of common beliefs, principles, objectives and concerns has been established, people will manage their own tasks and will take voluntary responsibility to improve processes they own’’.

- Recognition of the importance of implementing a system to provide information to managers about quality processes which enable them to plan, control and evaluate performance.

Issues in managing quality in supply chain:

- Specification and standardization:

Specification: A specification for an item has been defined as ‘a statement of the attributes of a product or service. It is basically a description of an item, its dimensions, analysis, performance or other relevant characteristics in sufficient detail to ensure that it will be suitable in all aspects for the purpose for which it is intended.

There are two main approaches to specification that are performance and conformance.

- The idea of performance specification is that a clear indication of the purpose, function, application and performance expected of the supplied material or service is communicated and the supplier is allowed or encouraged to provide an appropriate product. In this case, the detailed specifications is in the hands of the supplier where applicable, performance specifications are to be preferred in that they allow a wider competition and enable suppliers to suggest new or improved ways of meeting the requirements.

- Conformance specifications apply in situations where the buying organisation lays down clear and unambiguous requirements that must be met (In this case the specification is of the product, not the application). This type of specification is necessary where for example items for incorporation in an assembly are required or where a certain chemical product is to be acquired for a production process. It has been said that specifications restrict innovation.

Additional methods of specification:

- Use of brand or trade name: This will be applicable under the following circumstances:

- When manufacturing process is secrete or covered by a patent

- When manufacturing process of the vendor call a high degree of skill that cannot be exactly defined in a specification

- When only small quantities are bought so that the preparation of the specifications by the buyer is impracticable

- By sample: The sample can be provided either by buyer or seller and is useful method of specification in relation to printing and some raw materials e.g. cloth. When sample specifications are used:

- The bulk must correspond with the sample in quality

- The buyer must have a reasonable opportunity of comparing the bulky with the sample

- The goods must be free from any defect making their quality unsatisfactory which a reasonable examination of the sample would not reveal.

The value of specifications:

Specification will ensure that:

- All commodities specified will be suitable for their intended purpose when put in place

- Materials is of a consistent quality at all times

- The inspection or testing to be applied to goods purchased is notified in advance to the inspection section and to suppliers

- In respect of the purchase of the specified items, all suppliers will have the same date on which to base the quotations

Preparation of specifications:

- Avoid over-specification: This may lead to goods becoming more expensive and also may be difficult to find a manufacturer willing to quote

- Avoid under-specification since this may lead to inferior goods and services

- In order to be practicable, pay attention to convenience in handling and storage

- If there is to be inspection after delivery, the specifications ought to state what tests are to be applied

- If any special marking or packing is wanted, include the relevant instructions in the specifications.

Standardization:

This is the process of agreeing and adopting generic specification or descriptions of the items required. Standardization can also be defined as the process of grouping like items together in order to simplify examination of the complete range of any given type of items within the store. A standard differs from specification in that while every standard is a specification not every specification is a standard. Standard may be distinguished according to their subject –matter, purpose and range of application.

Advantages of standardization:

- There is accurate comparison of quotation since all prospective suppliers are quoting for the same thing.

- Clear specification helps to achieve reliability and reduce costs

- Less dependability on specialist suppliers and greater scope for negotiation

- Facilitation of international sourcing by reference to ISO standards.

- Reduction in error and conflicts thus increasing supplier goodwill.

- Quality is easier to monitor because visual inspection is easier and use of tried or tested items means that defects are less likely to occur.

- It gives clear specification and removal of any uncertainty as to what is required on part of both buyer and the supplier.

- Save time and money by eliminating the need to prepare specifications each time and reducing the need for explanatory telephone calls.

- Easier communication and less room for misunderstanding and disputes between buyers and users.

- Save inventory cost through variety reduction.

After standardization is introduced the following attributes should be observed:

- Ensure specifications are observed

- Ensure new specifications are suitably revised and approved.

- Ensure old specifications are reviewed, replaced, amended or even eliminated if they are not necessary.

Variety reduction:

This is the process of reducing the number of varieties stocked to a controlled workable minimum.

Procedure for variety reduction:

Variety reduction involves a complete examination of the list of commodities stocked to determine:

- The use or users for which each item is intended

- Which items have similar characteristics and can be used as substitutes for each other

- What range of sizes is essential

- Which items can be eliminated

- What specifications are necessary for retained items

Reasons that lead to variety reduction:

(1)Lack of specification when procuring items

(2) Where there are many suppliers of the same item

(3) Different sizes of containers or packages for items

(4) Lack of guidelines on how to use stocked items

(5) When there are varieties of the same item

Advantages of variety reduction:

(1)Reduction of stock holding cost

(2) Release of money tied up in stocks

(3) Easier specification while ordering

(4) Narrow range of inventory which leads to reduction in administrative cost

(5) Reduced supplier base: facilitates the building of long term relationship and supplier development.

Managing service quality:

Service quality is about ensuring customers, both internal and external, get what they want. As the technology brings markets, people and products ever closer, it is the single most effective and sustainable means of differentiation between competing companies. Managing service quality is packed with case histories, insights and guidance to the latest and most insightful academic thought in the field of service quality senior managers and board directors share with junior employees ideas, experience and advice as they strive for excellence in service quality. For an organization to succeed, intensely managing service quality is absolutely essential. It is only through customer alignment that the organization is on track toward a single, shared vision of customer focus and customer value; a vision that energizes people and the organization to accomplish extraordinary things. In order to embrace proper management based on service quality aspects the following concepts should invariably be focussed on:

- Voice of the customer

- Customer focus

- Customer alignment

- Linking the customer to results

TECHNIQUES OF QUALITY ASSURANCE:

The traditional tools to help organisations to understand their processes with a view to improving their quality techniques encompass:

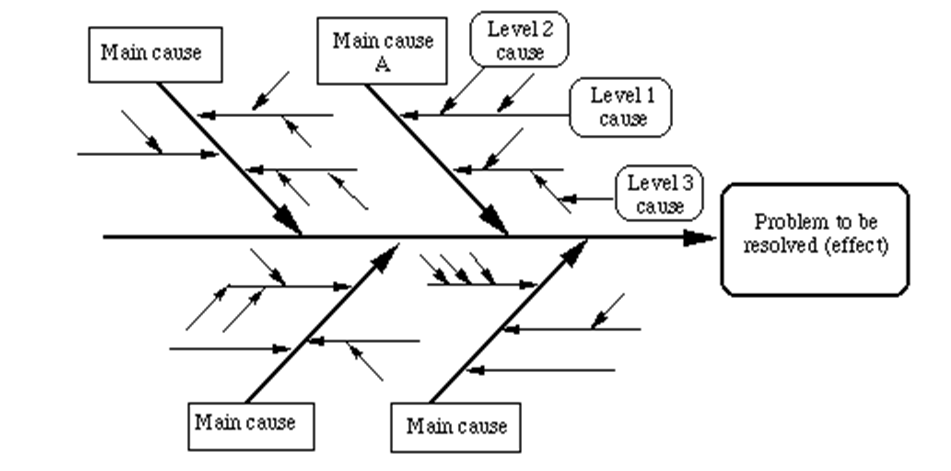

- Cause and effect diagrams:

The cause-and-effect diagram is a method for analysing process dispersion. The diagram’s purpose is to relate causes and effects. Three basic types are: Dispersion analysis, Process classification and cause enumeration. Effect = problem to be resolved, opportunity to be grasped, result to be achieved. Excellent for capturing team brainstorming output and for filling in from the ‘wide picture’. It helps to organise and relate factors, providing a sequential view. It also deals with time direction but no quantity can become very complex. It can also be difficult to identify or demonstrate interrelationships.

Cause and Effect, Fishbone, Ishikawa Diagram:

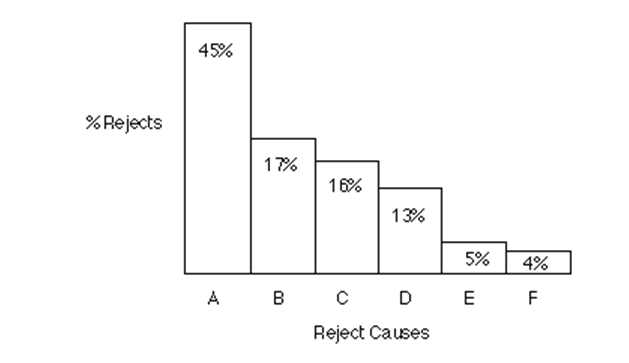

Pareto principle:

The Pareto principle suggests that most effects come from relatively few causes. In quantitative terms: 80% of the problems come from 20% of the causes (machines, raw materials, operators etc.); 80% of the wealth is owned by 20% of the people etc. Therefore effort aimed at the right 20% can solve 80% of the problems. Double (back to back) Pareto charts can be used to compare ‘before and after’ situations and also can be used to check general use, to decide where to apply initial effort for maximum effect.

Pareto principle:

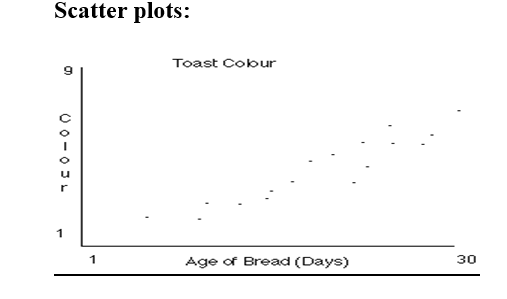

Scatter diagram:

A scatter plot is effectively a line graph with no line – i.e. the point intersections between the two data sets are plotted but no attempt is made to physically draw a line. The Y axis is conventionally used for the characteristic whose behaviour is used to predict and use to define the area of relationship between two variables.

Warning: There may appear to be a relationship on the plot when in reality there is none, or both variables actually relate independently to a third variable.

- Control charts:

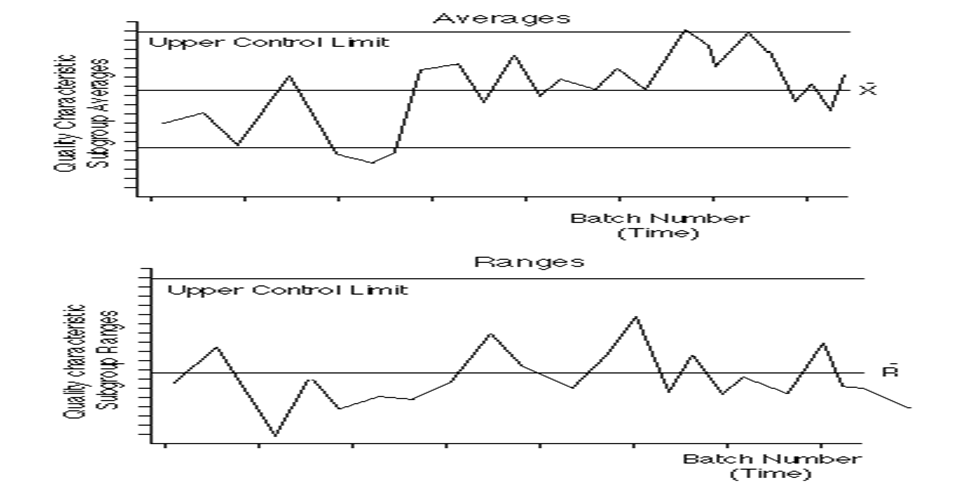

Control charts are a method of Statistical Process Control, SPC. (Control system for production processes). They enable the control of distribution of variation rather than attempting to control each individual variation. Upper and lower control and tolerance limits are calculated for a process and sampled measures are regularly plotted about a central line between the two sets of limits. The plotted line corresponds to the stability/trend of the process. Action can be taken based on trend rather than on individual variation. This prevents over-correction/compensation for random variation, which would lead to many rejects.

Control chart:

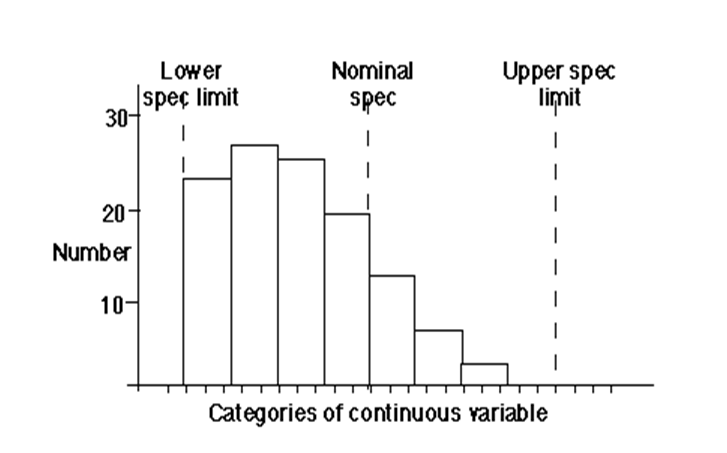

- Histogram or Bar Graph:

A Histogram is a graphic summary of variation in a set of data. It enables us to see patterns that are difficult to see in a simple table of numbers. It can also be analysed to draw conclusions about the data set.

A histogram is a graph in which the continuous variable is clustered into categories and the value of each cluster is plotted to give a series of bars as above. The examples below reveal the skewed distribution of a set of product measurements that remain nevertheless within specified limits. Without using some form of graphic this kind of problem can be difficult to analyse, recognise or identify.

Histogram or bar Graph:

- Check sheets

A Check Sheet is a data recording form that has been designed to readily interpret results from the form itself. It needs to be designed for the specific data it is to gather. It is used for the collection of quantitative or qualitative repetitive data and also it is adaptable to different data gathering situations. Minimal interpretation of results is required. It is easy and quick to use. No control for various forms of bias – exclusion, interaction, perception, operational, non-response, estimation.

- Check list:

A Checklist contains items that are important or relevant to a specific issue or situation. Checklists are used under operational conditions to ensure that all important steps or actions have been taken. Their primary purpose is for guiding operations, not for collecting data. Generally used to check that all aspects of a situation have been taken into account before action or decision making.

Value analysis and Value engineering:

Value analysis:

This is a systematic procedure aimed at ensuring that necessary functions are achieved at minimum cost without detriment to quality, reliability, performance and delivery. Value analysis can also be defined as the process of analyzing a product or a process to determine aspects or elements that do not add value and have the same eliminated. Value analysis results in the orderly utilization of alternative materials, newer processes, and abilities of specialist suppliers. It focuses manufacturing and purchasing attention on one objective: equivalent performance at lower cost. Having this focus, it provides step-by-step procedures for accomplishing its objective efficiently and with assurance.

Value analysis procedure:

The job plan for value analysis project comprises the following stages:

- Project selection: what project shows the greatest potential for savings etc

- Information stage: Obtain essential information relating to the items under consideration, define the functions of the product etc

- Speculation stage: Have a brain storming session in which many ideas are put forward for achieving the desired function, reducing costs or improving the product

- Investigation stage: Selects the best ideas produced at the speculation stage and evaluate their feasibility

- Proposal stage: Recommendations be presented to the level of management able to authorise the suggested changes

- Implementation stage: When approved by the responsibility executive, the agreed recommendations will be progressed through the normal production, purchasing or other procedures.

Purchasing and value analysis:

Where no value analysis exists, all buyers should be encouraged to understand and apply the approach. Purchasing can make the following contributions:

- Provision of information concerning:

- Materials and components

- Material cost of bought-out components

- Use of supplier standard part instead of special

2) Suggestions for buying economics such as:

- Economic order quantities

- Reduction costs of packing, handling and transportation

- Alternative reliable suppliers etc

3) Encouraging supplier participation: This involves examining with suppliers, the function of the items being analysed and seeking their specialist advice as to how the cost can be reduced.

Value engineering:

This is the application of value analysis at the pre-production or development stage. Value engineering can also be defined as a methodological systematic study of all phases of the design of a given item or process in relation to the function (value) of the finished product or processes to perform.

It is imperative to note that the terms value analysis and value engineering are invariably used synonymously. However, the distinction may be summarized by the statement that value analysis is concerned with cost correction while value engineering is concerned with cost avoidance. The basic organisational approaches to value analysis and value engineering include specialized staff approach (value analyst) the cross-functional team approach (committees members drawn from all departments) and the staff training approach. Developing understanding of the concept and working knowledge of techniques among most professional and operating personnel responsible for specifying purchasing and using production materials plays a significant role in perfection of both value analysis and value engineering.

Failure models and effect analysis (FMEA):

FMEA is defined as a systematic approach that applies a tabular method to aid the thought

process used by engineers to identify potential failure modes and their effects.

Types of FMEA:

The analyses take three forms:

1) Systems FMEA is used to analyse systems and subsystems in the early concept and design stages. System function is the design or purpose(s) of the system and is derived from customer wants. It can also include safety requirements, government regulations and constraints.

2) Design FMEA is used to analyse products before they are released to production.

3) Process FMEA is used to analyse products before they are released to the customer.

The preparation of an FMEA:

The Ford motor company which was the first of the UK motor manufacturers to request suppliers to use FMEA in their advance quality planning recommends a team approach led by the responsible system, product or manufacturing/assembly engineer who is expected to involve representatives from all affected activities. Team members may be drawn from design, manufacturing, assembly, quality, reliability, service, purchasing, Testing, supplier and other subject experts as appropriate. The team leader is also responsible for keeping the FMEA updated. For proprietary designs, the preparation and updating of FMEAs is the responsibility of the suppliers.

With a design FMEA, for example the team is initially concerned with identifying how a part may fail to meet its intended function. Starting with the failure modes with the highest severity ratings the design FMEA team then ascertains the possible causes of failure based on two assumptions:

-That the part is manufactured/assembled within engineering specifications

-That the part design may include a deficiency that may cause an unacceptable variation in the manufacturing or assembling process

The team then proceeds to ascertain:

- The cumulative number of failures that could occur over the life of the part

- Design evaluation techniques that can be used to detect the identified failure causes

- What design actions are recommended to reduce the severity, occurrence and detection ratings

Advantages of FMEA approach:

- Improved quality, reliability and safety of products

- Improved image and competitiveness

- Increased customer satisfaction

- Reduced in the product development timing and cost

- Documentation and tracking of actions to reduce risk

Disadvantages of FMEA approach:

FMEA is viewed as hard, slog; more use should be made of computerised aids to reduce the effort of preparing and updating the FMEA. The main difficulties are related to time constraints and lack of understanding of the importance of FMEA, training and commitment.

Quality function deployment:

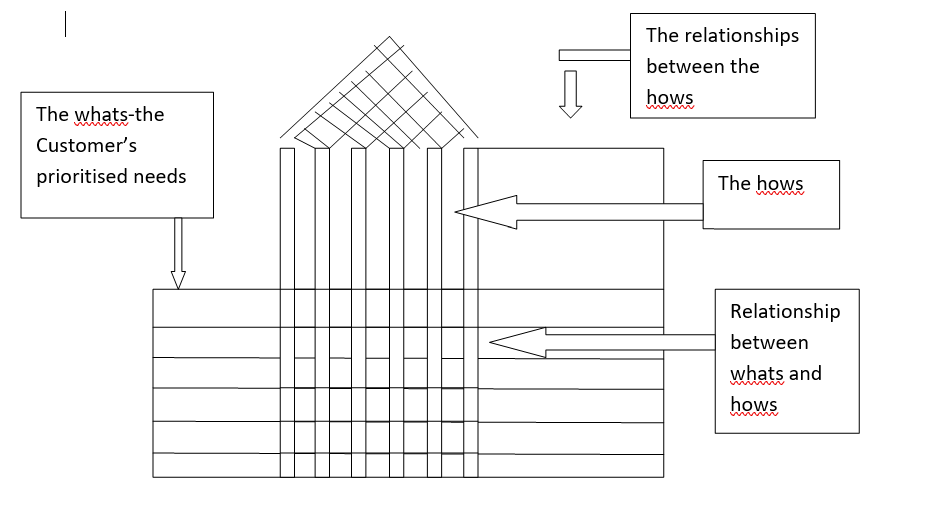

Quality function deployment (QFD) is a complex technique developed in Japan. QFD is a cross-functional team approach and incorporates the needs of the customer (the whats), which have been prioritised, hence QFD is also known as the voice of the customer. These whats are recorded on the left of the matrix. The hows are the ways that the team identify hows are recorded in the centre block of the matrix, the strength of the relationship being recorded by a designated symbol. The roof of the matrix records the relationship between the various hows that have been identified. These can be strongly or weakly positive or negative and this again is recorded by some assigned symbol. The benefits of QFD are said to be a better designed product with fewer design changes, giving a quicker time to market and ultimately a satisfied and loyal customer.

Simplified QFD matrix: